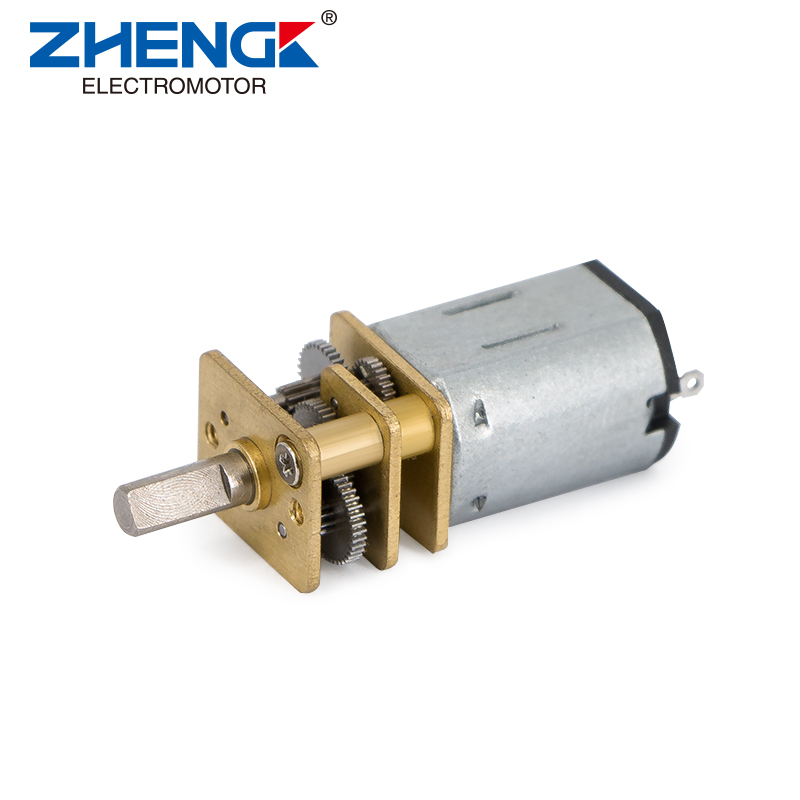

High-Quality 12V Gear Motor from Zhengke - Reliable Manufacturer for Your Needs

The 12V Gear Motor from Zhejiang Zhengke Electromotor Co., Ltd. is designed to deliver exceptional performance and reliability in various applications. This robust gear motor is engineered to provide High Torque while ensuring energy efficiency, making it ideal for robotics, automation systems, and small machinery, With a compact design, the motor fits seamlessly into tight spaces without compromising on power. Its durable construction guarantees longevity and resistance to wear, essential for continuous operation in demanding environments. The 12V input voltage allows for easy integration into existing systems, while its variable speed options make it versatile for different tasks, Zhejiang Zhengke Electromotor Co., Ltd. prides itself on using advanced manufacturing techniques, ensuring that each gear motor meets stringent quality standards. Choose the 12V Gear Motor for your project and experience the perfect blend of performance, reliability, and versatility. Explore new possibilities with a trusted partner in electromechanical solutions

Best Strategies For 12v Gear Motor Dominates Pioneers in the Field

In today's competitive landscape, leveraging the best strategies for 12v gear motors can significantly impact your business's success and efficiency. Our extensive experience in manufacturing various gear Dc Motors positions us as pioneers in this field. With a robust research and development team backed by advanced equipment, we are dedicated to innovating and optimizing our products to cater to the evolving needs of global buyers. A key strategy is to focus on quality and reliability. Our skilled engineers and workers ensure that each gear motor is crafted to meet high industry standards, reducing downtime and maintenance costs for your operations. By offering technical support and detailed product knowledge, we empower our customers to make informed decisions, ultimately setting them up for success in their respective markets. Moreover, we understand the importance of tailored solutions to meet the unique requirements of diverse applications. Partnering with us means gaining access to not only superior products but also professional technology that drives efficiency and performance. As we continue to dominate this field, we invite global purchasers to collaborate with us to achieve unparalleled innovation and growth.

Best Strategies For 12v Gear Motor Dominates Pioneers in the Field

| Strategy | Description | Benefits | Applications |

|---|---|---|---|

| Efficient Gear Design | Utilizing optimized gear shapes to minimize friction and energy loss. | Improved torque output and energy efficiency. | Robotics, Automation Systems |

| Motor Control Algorithms | Implementing advanced control algorithms for better precision in motor operation. | Enhanced speed control and accuracy. | Drones, Electric Vehicles |

| Heat Management | Applying effective thermal management techniques to prevent overheating during operation. | Increased reliability and longevity. | Industrial Equipment, Home Appliances |

| Customization | Tailoring gear motors to specific application requirements, including size, weight, and power needs. | Optimized performance for specialized tasks. | Medical Devices, Precision Machinery |

| Integration with IoT | Equipping gear motors with IoT capabilities for remote monitoring and operation. | Improved data collection and analysis, remote control. | Smart Homes, Industrial Automation |

China Top 12v Gear Motor Where Innovation Meets 2025 Delivers Unmatched Quality

D

Daniel Lee

The craftsmanship is excellent. I appreciated the outstanding support from their knowledgeable team.

19 June 2025

Z

Zoe Thompson

Impressive overall! The quality of the product and professionalism of the service were noteworthy.

03 July 2025

L

Lila Rivera

This product has surpassed my expectations. Their customer service followed up promptly.

13 June 2025

G

Gavin Taylor

Very reliable and sturdy! The support team was knowledgeable, making the experience wonderful.

07 June 2025

C

Cecilia Adams

Amazing product! The support I received was attentive, ensuring everything went smoothly.

03 June 2025

L

Leo Turner

Impressive quality! Their after-sales team was a pleasure to work with.

30 June 2025