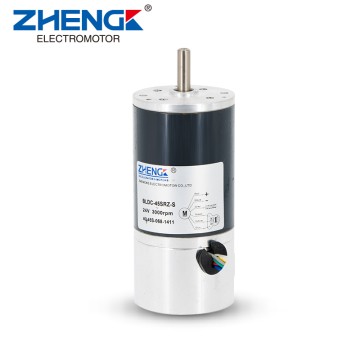

Zhengke High-Quality BLDC Torque Motors from Leading Factories and Manufacturers

When sourcing a **DC Torque Motor Product**, quality and performance are my top priorities. Our BLDC torque motors are designed for maximum efficiency, making them suitable for a range of applications. I can connect you with reputable suppliers and manufacturers, ensuring optimal pricing and reliability. At Zhejiang Zhengke Electromotor Co., Ltd., we are committed to innovative designs and high craftsmanship. Every motor undergoes rigorous quality control measures, ensuring you invest in a durable and high-performance product. We recognize the importance of dependable partners in your supply chain, providing flexible order quantities and tailored solutions to meet your specific needs.The Secret to Bldc Torque Motor Product Service From Concept to Delivery

In the competitive landscape of electric motor manufacturing, understanding the intricacies of product service is crucial for global buyers seeking reliable partners. Our company specializes in producing high-quality BLDC torque motors, ensuring that each step of the process, from concept to delivery, is meticulously handled. With years of experience in manufacturing various gear Dc Motors, we leverage our strong R&D team, advanced equipment, and skilled engineers to meet the specific needs and standards of our clients. The journey begins with an in-depth consultation, where we collaborate with our customers to understand their unique requirements and design specifications. Our R&D team utilizes cutting-edge technology to innovatively enhance our product offerings. As we move into production, our skilled workers and advanced machinery ensure that each motor is manufactured with precision and care. Rigorous quality control measures are implemented at every stage to guarantee that our products not only meet but exceed industry standards. Finally, our commitment to professional technology extends beyond manufacturing—our dedicated customer service team guides clients through the delivery process, ensuring timely and reliable shipment. By choosing us as your partner, you gain access to a seamless service that transforms your ideas into high-performance motors, ultimately empowering your business to thrive in the global marketplace.

The Secret to Bldc Torque Motor Product Service From Concept to Delivery

| Stage | Description | Duration (Weeks) | Key Activities | Outcome |

|---|---|---|---|---|

| 1. Concept Development | Initial brainstorming and idea validation. | 2 | Market research, idea sketches, feasibility studies. | Clear project direction and objectives. |

| 2. Design Phase | Detailed design and prototyping. | 4 | CAD modeling, material selection, prototype testing. | Functional prototype ready for testing. |

| 3. Testing & Validation | Tests to ensure design meets specifications. | 3 | Performance tests, reliability assessments, safety checks. | Validated design, ready for production. |

| 4. Manufacturing | Producing the final product. | 6 | Supplier coordination, assembly line setup, quality assurance. | Final product ready for distribution. |

| 5. Delivery & Support | Product distribution and customer support. | 2 | Logistics planning, customer training, warranty setup. | Successful product launch and customer satisfaction. |

Making Smart Choices Bldc Torque Motor Product More Than a Supplier - A Partner Ahead of the Curve

S

Sophia Baker

Excellent product! The staff provided great assistance and were very knowledgeable about the details.

31 May 2025

D

David Wright

This product is built to last. The support staff are true professionals, making the whole experience smooth.

26 May 2025

S

Scarlett Hill

Truly impressed! The quality is superb, and the support team was a real pleasure to work with.

03 July 2025

L

Lily Martinez

I appreciate the quality and the thoroughness of the customer service team.

30 June 2025

I

Isaiah Young

Quality meets expert support! I felt very guided through my purchase.

19 June 2025

S

Sophie Green

Excellent product! The staff were knowledgeable and really cared about my experience.

15 May 2025