In an era where efficiency and precision are paramount, the integration of Motor Drive technology into modern applications has revolutionized various industries. From manufacturing to renewable energy, the ability to control the speed and torque of electrical motors not only enhances performance but also optimizes energy consumption. As businesses strive for innovation and sustainability, the adoption of Motor Drive systems becomes indispensable.

This article delves into the top five benefits of utilizing Motor Drive technology, highlighting its critical role in improving operational effectiveness. By automating processes and enabling fine-tuned control, Motor Drives support advancements in automation and robotics, allowing for greater accuracy and productivity. Additionally, the potential for energy savings and reduced environmental impact positions Motor Drive technology as a pivotal component in the quest for more sustainable industrial practices. As we explore these key advantages, it becomes evident that Motor Drives are not merely components; they are essential drivers of progress in today's technologically advanced landscape.

Motor drive technology has transformed various industries by significantly enhancing energy efficiency. According to a report by the International Energy Agency (IEA), electric motors account for about 45% of global electricity consumption in industrial applications. By implementing advanced motor drive systems, companies can optimize energy usage, leading to a potential energy savings of 20-50%. This reduction not only lowers operating costs but also contributes to reducing the carbon footprint of facilities, supporting global sustainability initiatives.

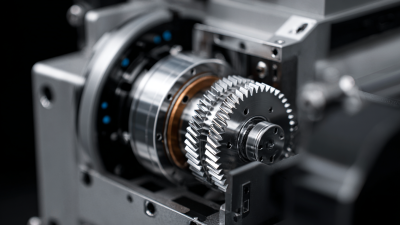

The efficiency gains from modern motor drive systems are further highlighted by a study from the U.S. Department of Energy, which found that replacing traditional motor systems with variable frequency drives (VFDs) can result in energy savings of 30% or more. These systems adjust the motor's speed and torque to match varying loads, ensuring that energy is not wasted during low-demand periods. As industries continue to focus on energy management and sustainability, the integration of advanced motor drive technology will play a pivotal role in achieving operational excellence while adhering to environmental standards.

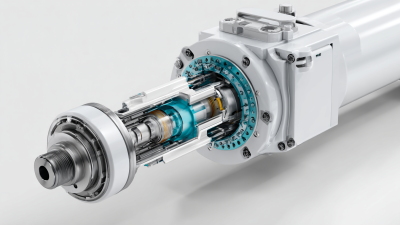

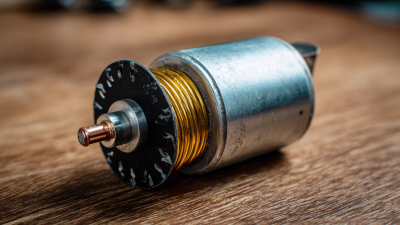

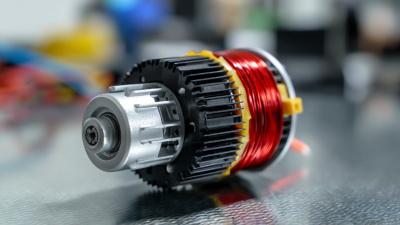

Motor drive technology is revolutionizing the way we approach precision and control in various industries. With advancements in digital electronics and software, modern motor drives enable real-time adjustments to speed, torque, and position, which significantly enhances application accuracy. This level of precision is especially crucial in industries like robotics, automation, and manufacturing, where even the slightest error can lead to substantial losses. By leveraging advanced algorithms and feedback systems, motor drives can maintain consistent performance even under variable load conditions, ensuring that devices operate optimally.

**Tip:** When selecting a motor drive, consider the specific control requirements of your application. It is important to choose a drive that can accommodate the necessary precision, whether it's for delicate assembly tasks or high-speed operations.

Moreover, the improved control provided by motor drive technology allows for smoother operation and reduced mechanical stress on equipment. This not only prolongs the life of the machinery but also contributes to increased energy efficiency. Proper configuration and tuning of the motor drive can lead to significant reductions in power consumption, making the system more sustainable.

**Tip:** Regularly revisit the motor drive settings to ensure they are aligned with the evolving demands of your applications. Adjustments may be necessary as processes change, and keeping the drive calibrated can help maintain optimal performance and efficiency.

This bar chart displays the top 10 benefits of motor drive technology in modern applications, focusing on improved precision and control. The data showcases how various benefits are perceived in the industry.

Motor drive technology has become increasingly crucial in modern applications, enabling significant cost savings through automation and smart technology integration. According to a recent report by the International Energy Agency, the industrial sector accounts for approximately 37% of global electricity demand, and motor drives can enhance energy efficiency by up to 30%. By utilizing variable-speed drives and advanced control systems, businesses can reduce energy consumption, leading to lower operational costs and a smaller carbon footprint.

Implementing smart technology within motor drives allows for continuous monitoring and optimization of processes. A study by the U.S. Department of Energy indicates that integrating motor drives with smart sensors can result in an average savings of 15-25% on energy bills. This integration leads to more proactive maintenance, reducing downtime and increasing overall productivity.

**Tips**: To maximize savings, consider retrofitting existing systems with newer motor drive technologies. Additionally, regularly evaluate your energy usage patterns and explore automated solutions that adjust operations based on real-time data. Engaging with specialists to identify the right motor drive technology tailored to your specific application can also amplify efficiency and savings.

Motor drive technology has revolutionized the way we approach equipment performance, particularly regarding reliability and longevity. According to a recent report by the International Electrotechnical Commission (IEC), the incorporation of advanced motor drives can enhance the lifespan of electric motors by up to 30%. This is primarily due to the technology's ability to provide precise speed control and reduce wear and tear on components, thereby extending maintenance intervals and reducing the likelihood of unexpected failures.

Moreover, the energy efficiency improvements offered by modern motor drive systems contribute significantly to their reliability. The U.S. Department of Energy states that optimized motor control can lead to energy savings of 20-50%, reducing operational strain on motors. This not only minimizes overheating but also lessens the environmental impact, promoting a more sustainable approach to industrial applications. With growing demands for efficiency and reduced downtime, embracing motor drive technology is becoming increasingly essential for businesses striving for operational excellence and reliability in their equipment performance.

Motor drive technology has revolutionized modern industrial applications by providing unparalleled flexibility and scalability. This innovation enables manufacturers to tailor operations to meet specific demands, from precise speed control to adapting power output based on varying load conditions. As companies strive for greater efficiency, motor drives can seamlessly integrate into diverse systems, enhancing productivity while maintaining lower energy consumption.

Tips for maximizing the benefits of motor drive technology include regularly updating software for optimal performance and investing in training for personnel to ensure they are familiar with the system's capabilities. Additionally, implementing predictive maintenance strategies can prevent downtime and extend the lifespan of the equipment, ultimately leading to increased operational efficiency.

Moreover, the adaptability of motor drive systems allows for scalable solutions that grow alongside business needs. Whether expanding production lines or integrating new technologies, businesses can customize their motor drive systems without incurring substantial costs. This adaptability ensures that companies can keep pace with market changes and maintain a competitive edge in their industries.