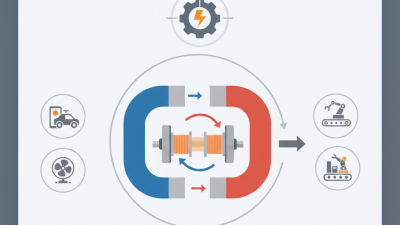

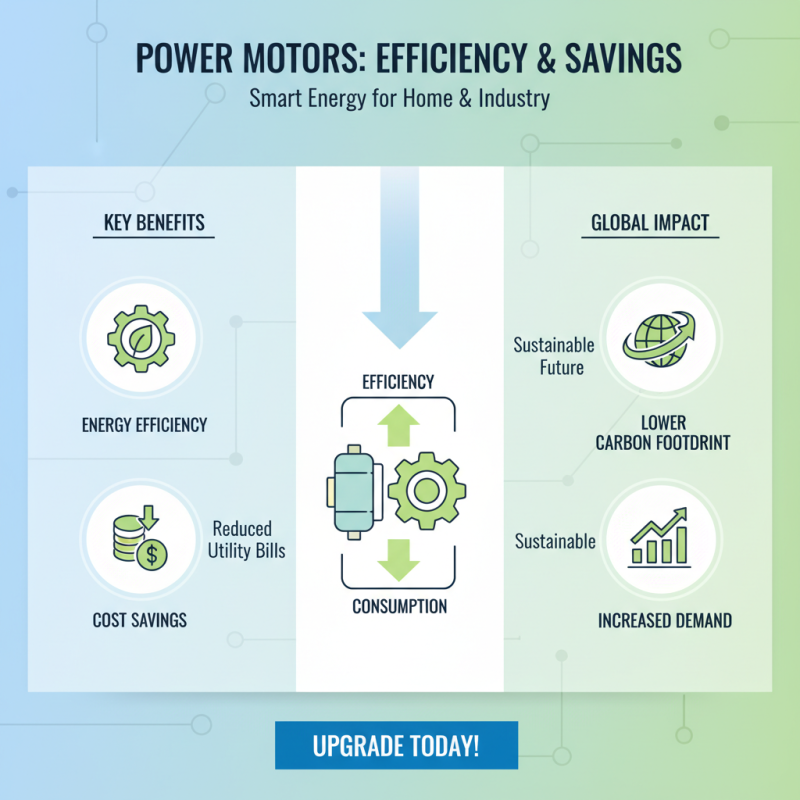

Power motors are essential components that drive efficiency and innovation in both residential and industrial settings. As technology advances, the availability and versatility of power motors have expanded, leading to their widespread adoption. These electric marvels not only enhance operational capabilities but also contribute to energy savings and sustainability, making them a vital investment for homeowners and businesses alike.

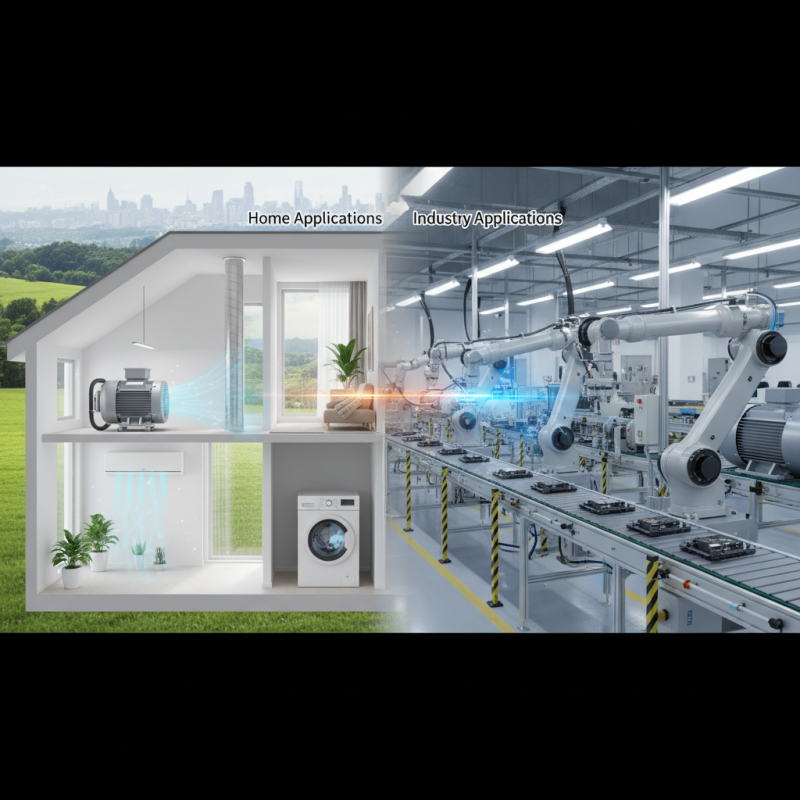

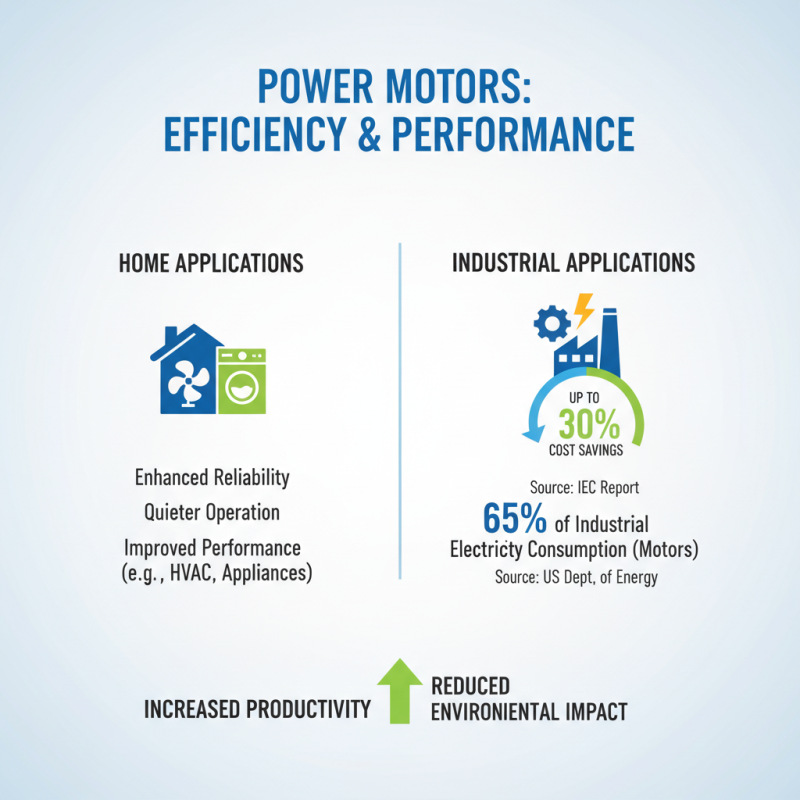

In home applications, power motors can be found in various systems, ranging from HVAC units to appliances, ensuring a comfortable and convenient living environment. Their ability to provide consistent power translates into better performance and reliability. In industrial applications, power motors facilitate automation, improving production lines and reducing labor costs. The efficiency gained from using power motors can lead to significant long-term savings and a positive impact on the overall bottom line.

In summary, understanding the top benefits of power motors is crucial for anyone looking to optimize their home or enhance their industrial operations. By embracing this technology, users can unlock new levels of productivity and efficiency, driving progress in a sustainable manner.

Power motors are becoming increasingly popular in residential applications due to their efficiency and versatility. These motors provide a reliable source of energy for various household devices, such as appliances, heating systems, and even home automation systems. One of the primary advantages of using power motors at home is their ability to operate quietly and smoothly, reducing noise pollution. This is particularly beneficial in residential areas where peace and quiet are valued.

Tips for selecting the right power motor for your home include considering the specific requirements of your devices. It's essential to assess the power needs and application of each motor, ensuring you choose one that fits your energy usage patterns. Additionally, prioritize energy-efficient models to save on utility bills and reduce your carbon footprint.

Another significant benefit of power motors in residential settings is their adaptability. They can be used for diverse applications, from powering garage doors to running smart home systems. This flexibility means homeowners can incorporate power motors into various aspects of their daily lives, enhancing convenience and automation. When planning to integrate power motors, consider consulting with a professional who can help determine the best options for your specific needs.

| Benefit | Residential Applications | Industrial Applications |

|---|---|---|

| Energy Efficiency | Lower energy bills, improved sustainability | Reduced operational costs, compliance with regulations |

| Reliability | Minimized downtime for home appliances | Increased uptime for production processes |

| Versatility | Applicable in HVAC systems, garage doors | Suitable for conveyors, pumps & heavy machinery |

| Compact Design | Space-saving installations in homes | Efficient use of space in factory layouts |

| Low Maintenance | Fewer service calls needed | Saves time and resources in maintenance |

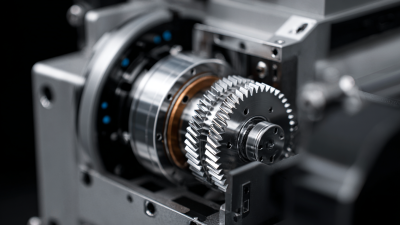

Power motors are crucial in industrial applications, offering a range of benefits that enhance operational efficiency and productivity. According to a report by the International Energy Agency (IEA), industrial motors account for about 70% of electricity consumption in the manufacturing sector. By implementing energy-efficient power motors, industries can significantly reduce their energy costs while also minimizing their carbon footprint. These motors are designed to handle heavy loads and operate in demanding environments, making them ideal for various industrial processes.

One of the key benefits of power motors is their reliability and durability. Industrial environments often involve harsh conditions, including temperature fluctuations and exposure to dust or moisture. Power motors are built to withstand these challenges, leading to lower maintenance costs and reduced downtime. A study by the U.S. Department of Energy indicates that optimizing motor operation can yield energy savings of 10-30%, further showcasing their financial advantages in long-term use.

**Tip:** When selecting power motors for industrial applications, consider the motor’s efficiency rating. Higher efficiency models not only reduce energy consumption but can also qualify for government incentives, further decreasing initial investment costs.

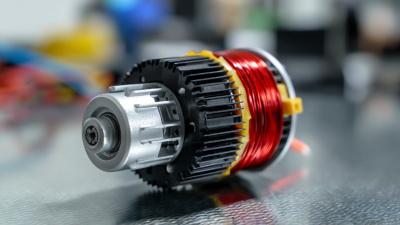

Another important aspect of power motors is their adaptability. They can be customized to meet specific performance needs and can easily integrate with various automation systems. The flexibility offered by power motors allows industries to scale operations rapidly in response to market demands. According to the World Economic Forum, industries that adopt adaptable technologies are better positioned to thrive in a competitive landscape.

**Tip:** Regularly monitor and assess the performance of your power motors to ensure they are operating at optimal levels, as this can help catch any inefficiencies early and maintain a productive workflow.

Power motors have become essential components in both home and industrial applications due to their impressive energy efficiency and potential for cost savings. As energy prices continue to rise, the demand for more efficient power solutions has never been more critical. By integrating power motors into various systems, homeowners and industries alike can significantly reduce their energy consumption, leading to lower utility bills and a reduced carbon footprint.

One effective way to maximize energy efficiency with power motors is to conduct regular maintenance checks. By ensuring that motors are clean and free of obstructions, their operational efficiency can be maintained, leading to optimal energy usage. Additionally, investing in variable speed drives can allow motors to adjust their speed according to the load requirements, thereby minimizing energy waste during low-demand periods.

Another tip for enhancing cost savings while using power motors is to choose the right motor for each specific application. Understanding the load requirements and selecting a motor that operates at its peak efficiency range can lead to substantial energy savings. Furthermore, implementing automated systems to monitor and manage motor performance can help identify inefficiencies in real-time, allowing for prompt corrective actions that prolong motor life and reduce operational costs.

Power motors have become essential components in both home and industrial settings due to their remarkable versatility. Their applications span a wide range of areas including HVAC systems, manufacturing equipment, and even household appliances. In residential environments, power motors can enhance energy efficiency and simplify everyday tasks, such as with electric fans and washers. In industrial applications, these motors power conveyor belts, pumps, and heavy machinery, playing a crucial role in streamlining operations and improving productivity.

Tips for selecting the right power motor for your application include assessing the required torque and speed, as these factors significantly impact performance. It's also advisable to consider the motor's efficiency rating, as this can lead to long-term cost savings on energy. Additionally, understanding the specific environment in which the motor will operate—such as exposure to dust, moisture, or extreme temperatures—can help in choosing a motor that will withstand the demands of its setting.

The versatility of power motors also allows for customization. Many applications benefit from motors that can be tailored to specific needs, such as variable speed control for precise processing in industrial equipment or quiet operation for home appliances. Exploring these features can lead to enhanced functionality and can optimize performance across various tasks, making power motors an invaluable asset in both home and industrial applications.

Power motors play a crucial role in enhancing performance and reliability in both home and industrial applications. According to a report by the International Electrotechnical Commission (IEC), energy-efficient motors can lead to operational cost savings of up to 30% when compared to standard motors. These benefits are particularly significant in industrial settings where motors account for about 65% of the total electricity consumption, as noted in the U.S. Department of Energy's findings. By investing in high-performance power motors, industries can not only achieve greater productivity but also reduce their environmental impact due to lower energy consumption.

In residential settings, the impact of power motors extends to household appliances and home automation systems. The integration of advanced motors in these devices ensures smoother operation, lower noise levels, and improved longevity. For instance, energy-efficient motors in HVAC systems can increase reliability significantly, resulting in a reduction in unexpected breakdowns and maintenance costs. As highlighted in a recent report from the Electric Power Research Institute (EPRI), households equipped with modern power motors experience a marked improvement in comfort and energy savings.

Tips: When selecting power motors for your applications, consider looking for models with high efficiency ratings to ensure optimal performance. Additionally, regular maintenance is crucial; lubricating moving parts can extend the lifespan and reliability of these motors, ultimately leading to better productivity for both home and industrial use.