The 5 Rpm motor is an essential component in various applications across industries. Its low-speed operation is ideal for tasks requiring precision and control. Many businesses benefit from its unique features, making it a popular choice in manufacturing and automation.

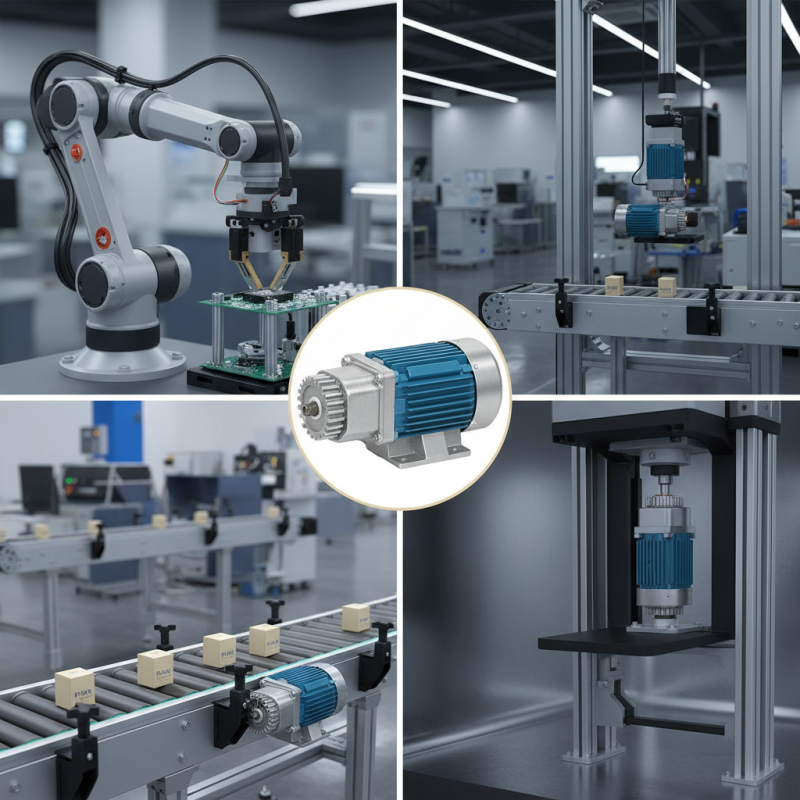

In robotics, the 5 Rpm motor provides smooth movement. This precision allows for intricate operations, ensuring accuracy in tasks like assembly and welding. Additionally, its compact size makes it suitable for confined spaces, but it can lack power in high-demand situations.

Another application is in conveyor systems. The 5 Rpm motor moves items steadily, facilitating consistent production. However, it may struggle with heavier loads. Understanding its capabilities and limitations helps users make informed decisions. This insight can prevent inefficiencies and enhance system performance.

5 RPM motors play a crucial role across various industries. These motors offer specific advantages, particularly in automation and control systems. Their low-speed operation makes them ideal for applications that require precision. For example, in conveyor systems, they ensure a steady flow of materials without sudden jolts. According to a recent study, industries utilizing slow-speed motors have reported a 30% increase in operational efficiency.

In agriculture, 5 RPM motors drive slow-moving machinery like seeders and irrigation systems. Their ability to maintain a consistent speed allows for better coverage and reduced waste. Research shows that farms using these motors can increase yield by 15%. However, the dependency on a singular motor speed may pose challenges during rapid changes in demand.

Manufacturing processes also benefit from these motors. They power assembly lines where parts must be accurately positioned. In robotic applications, their steady movement reduces wear and tear, extending machinery lifespan. Yet, the limited speed range might not meet the needs of all manufacturers, leading to potential inefficiencies when high-speed operations are required. Balancing speed and torque is essential.

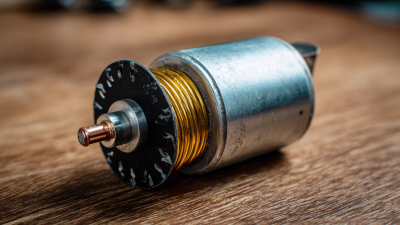

5 RPM motors are increasingly favored in various mechanical applications. Their low rotation speed provides unique advantages that enhance efficiency and reliability. According to industry reports, these motors excel in tasks requiring precise motion control. This control allows for improved accuracy in assembly lines, reducing errors that could lead to costly downtimes.

One significant benefit of 5 RPM motors is their energy efficiency. Operating at lower speeds generally translates to reduced energy consumption. Studies from mechanical engineering journals show that systems utilizing 5 RPM motors can see up to 30% energy savings compared to higher RPM alternatives. This is particularly beneficial in continuous operation environments, where every percentage point of efficiency can lead to substantial savings over time.

The design of these motors often contributes to less wear and tear. The slower speed means that components experience less stress. However, it is essential to note that the torque output may not be suitable for all applications. Some users may find limitations when high torque is necessary. Balancing requirements with motor capabilities is crucial for optimal performance in mechanical systems.

| Application | Description | Key Benefits |

|---|---|---|

| Conveyor Systems | Used for transporting materials in various industries. | Consistent speed, low energy consumption, and high reliability. |

| Automated Doors | Powering sliding and revolving doors in commercial spaces. | Safety, smooth operation, and programmable control. |

| Robotic Arms | Used in manufacturing for precise movements. | High control precision, durability, and ease of integration. |

| Aquarium Aerators | Used for ensuring water circulation and oxygenation. | Quiet operation, energy efficiency, and reliable performance. |

| Fans and Blowers | Used for cooling systems and air circulation. | Consistent airflow, low maintenance, and long lifespan. |

When comparing 5 RPM motors to other speed options, distinct advantages emerge. These motors excel in precision applications. For example, in assembly lines, slow rotation ensures careful positioning. It reduces the risk of damage to delicate components. Such control is rarely found in higher-speed motors.

However, there are downsides to consider. The torque output of 5 RPM motors can be lower than faster models. This might limit their use in heavy-duty tasks. Some projects may require higher speeds for efficiency. Exploring alternatives can be beneficial in these cases. Understanding the specific needs is crucial before making a decision.

Furthermore, the energy efficiency of 5 RPM motors can be a double-edged sword. They often consume less energy in low-speed applications, yet this might not hold for all situations. Balancing energy savings with performance needs is essential. This analysis helps clarify where 5 RPM motors fit best, making it clear that they are not always the first choice.

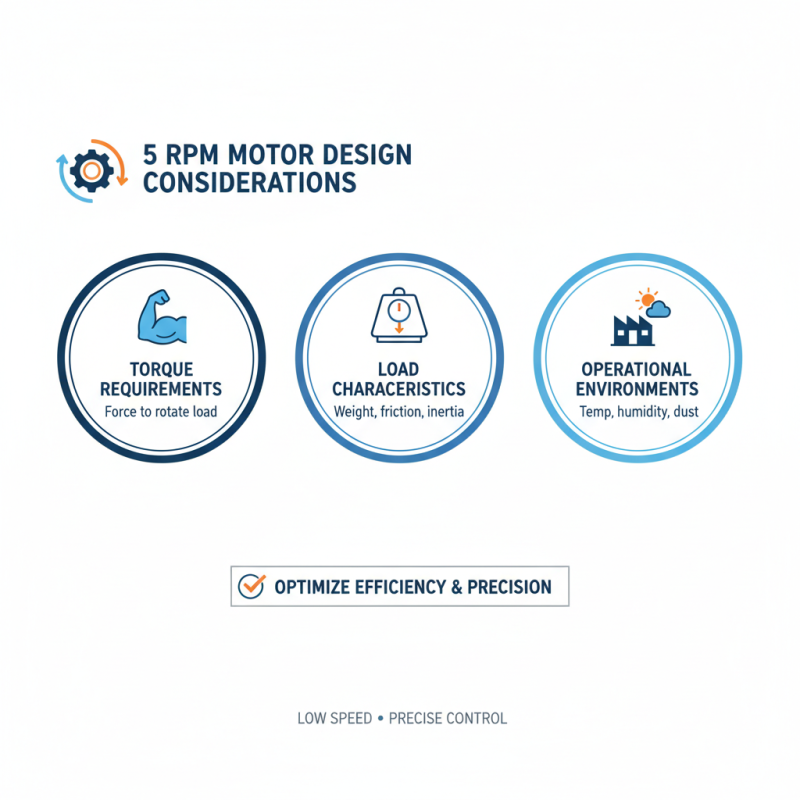

When utilizing 5 RPM motors, several design considerations must be prioritized. These motors are often used in applications requiring low speeds and precise control. Key factors include torque requirements, load characteristics, and operational environments. Understanding these elements helps in optimizing efficiency.

It's crucial to examine the torque requirements. A motor undersized for its application may struggle, leading to overheating. Load characteristics also play an essential role. The nature of the load, whether it’s constant or variable, affects performance. These motors require careful selection based on the specific application.

Operational environments pose another challenge. For example, high-temperature settings may necessitate additional cooling solutions. Moisture exposure can damage the motor’s components. It's essential to consider these factors to avoid operational failures. A thorough review of the design elements is necessary for achieving the best performance from a 5 RPM motor.

The future of 5 RPM motor technology presents exciting opportunities. These low-speed motors are finding new applications in various fields. For instance, they are increasingly used in automation and robotics. Their precision and stability make them ideal for repetitive tasks. As industries evolve, the demand for efficient motors keeps rising.

In the realm of renewable energy, 5 RPM motors play a crucial role. They can effectively drive systems like small wind turbines and solar trackers. Such applications help harness energy more reliably. Moreover, advancements in materials and control systems are expected. This could lead to lighter, more efficient motors. However, there are challenges. The balance between power and efficiency needs constant reevaluation. Technologies must be adapted and improved to meet the growing demands of modern applications.

Overall, the evolution of 5 RPM motors reflects broader trends. The push for smarter, sustainable solutions continues. As we explore these technologies, we must remain mindful of their limitations. Continuous improvement and innovation are vital for future advancements.