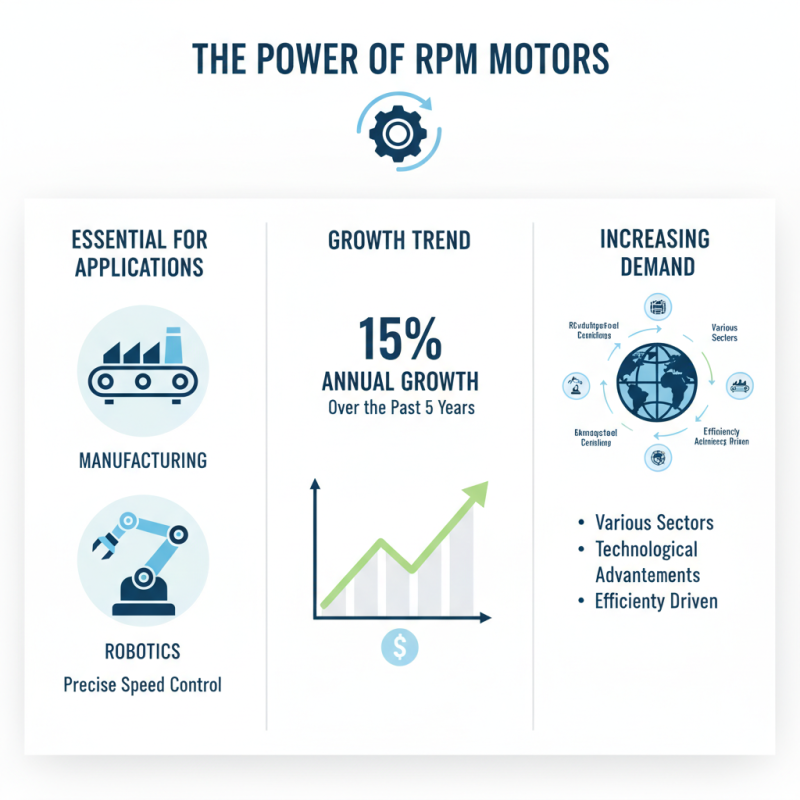

In the evolving landscape of industrial machinery, the demand for effective and reliable motors is undeniable. A recent industry report highlights a growing trend: the 7 RPM motor is gaining traction across various applications. This specific motor speed is becoming essential in sectors like automation and robotics. Innovation in motor technology drives this growth, but challenges remain.

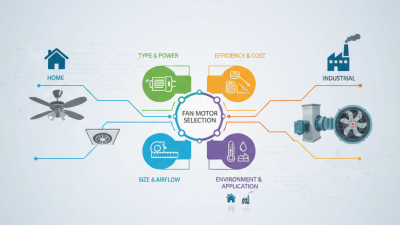

The need for efficiency is paramount. According to market analysis, the 7 RPM motor market is projected to expand by 15% annually. This growth reflects increased automation and energy-saving practices. Yet, selecting the right motor can be daunting. Factors like torque, power specifications, and durability must all be considered.

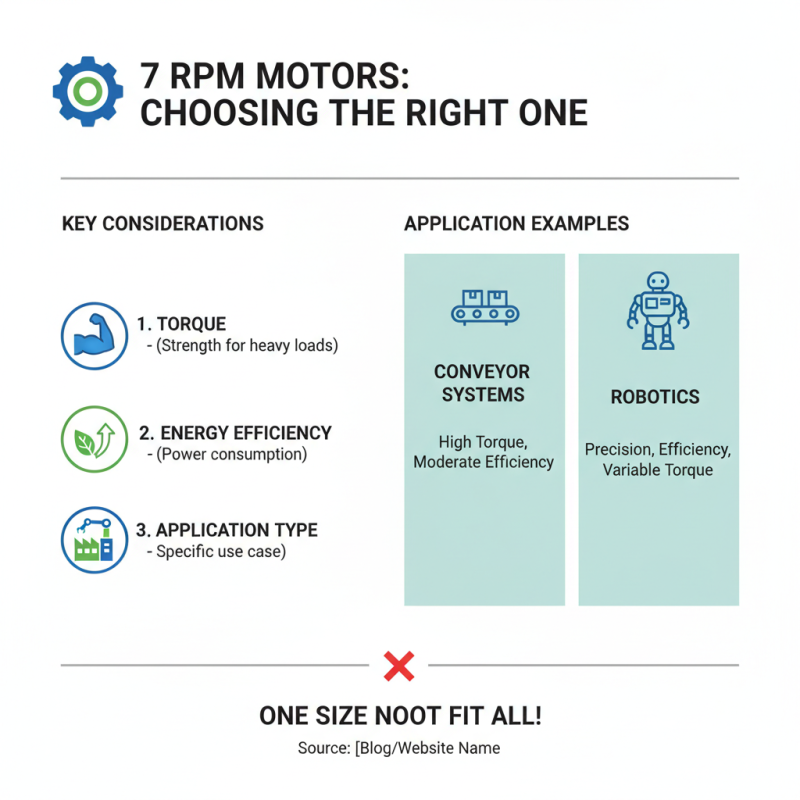

Not all 7 RPM motors are created equal. Users must evaluate their specific needs carefully. While performance data can guide them, occasional mismatches can occur. Finding the ideal motor means balancing cost, application, and longevity. It requires thoughtful reflection on where improvements can be made in efficiency and design. In 2026, choosing the right 7 RPM motor will be crucial for achieving operational success.

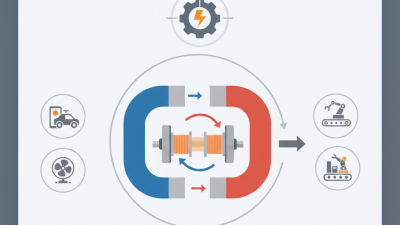

RPM motors play a crucial role in numerous modern applications. Their ability to provide precise speed control is essential for industries like manufacturing and robotics. Data from industry reports indicate that RPM motors have seen a growth of around 15% annually over the past five years. This trend highlights their increasing demand across various sectors.

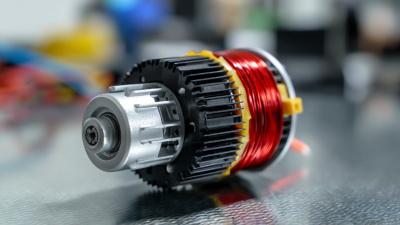

In terms of specifications, 7 RPM motors are particularly valued for their torque capabilities. They deliver high performance in tasks ranging from conveyor systems to automated assembly lines. Interestingly, many applications still underutilize the potential of RPM motors, leading to inefficiencies. Users often overlook matching the motor's specs to specific needs, causing operational issues.

Moreover, energy efficiency is another consideration. RPM motors have improved significantly, yet some designs still lack optimal energy consumption features. Reports suggest that up to 30% of these motors could be more efficient if upgraded. This presents an opportunity for manufacturers to enhance their design strategies. Continuous innovation in motor technology is crucial for addressing these challenges.

When selecting a 7 RPM motor, consider torque, efficiency, and durability. High torque ratings are crucial for applications requiring substantial force. Industry reports show that motors with a torque range of 5 to 10 Nm perform well in heavy-duty tasks. Choose a motor that can maintain consistent torque across different loads.

Efficiency matters significantly in motor selection. Motors with an efficiency rating above 85% help reduce energy costs. Lower efficiency can lead to increased heat production. Excess heat may shorten the motor's lifespan and create maintenance challenges. High-quality materials often contribute to better motor efficiency. Look for specifications indicating energy consumption rates.

Durability in design is another essential feature. Materials should withstand wear and tear in harsh environments. Some applications might expose motors to moisture or dust. IP ratings evaluate how well a motor can resist these conditions. An IP rating of 65 or higher offers solid protection against dust and water. Ultimately, balancing these factors can lead to a more effective motor choice.

This chart shows the performance comparison of various 7 RPM motors based on crucial factors like torque, efficiency, and weight. These factors are important for applications in robotics, automotive, and automation industries.

In 2026, several key industries will significantly rely on 7 RPM motors. These motors are crucial in manufacturing, where precision is essential. They ensure consistent speeds for conveyor belts, making product movement efficient. In food processing, these motors help in mixing ingredients smoothly. Consideration of hygiene and safety remains pertinent in these applications.

The renewable energy sector also adopts 7 RPM motors. They assist in wind turbine mechanisms, offering stability at low speeds. The challenge lies in integrating these motors effectively with existing systems. During testing phases, speed variations can occur, impacting energy production.

Healthcare devices represent another vital application area. 7 RPM motors are used in machinery like dental drills or surgical tables. Proper calibration is necessary here. Yet, the interaction of mechanical parts sometimes leads to unexpected results. Ongoing reflection on motor performance is crucial for these sensitive applications.

| Application | Industry | Motor Type | Power Rating (W) | Efficiency (%) |

|---|---|---|---|---|

| Conveyor Systems | Manufacturing | DC Gear Motor | 150 | 85 |

| Robotic Arms | Automation | Stepper Motor | 200 | 90 |

| Pumps | Water Management | AC Induction Motor | 300 | 80 |

| Agricultural Equipment | Agriculture | Brushless DC Motor | 250 | 92 |

| Medical Devices | Healthcare | Servo Motor | 100 | 88 |

When examining the best 7 RPM motors on the market, several factors come into play. Different applications put varying demands on these motors. For instance, some require high torque, while others prioritize energy efficiency. A motor suitable for a conveyor system could struggle in a robotics setting. Understanding these nuances is crucial.

In comparing leading models, it's clear that performance varies. Some motors excel in durability but may lack speed control features. Others showcase advanced technology for energy savings, yet they could be more expensive. It's important to weigh the costs against the benefits. Users need to assess their specific needs; not every motor suits all applications. This can lead to challenges in finding the perfect match.

Efficiency shouldn’t come at the price of reliability. The balance is tricky. A less expensive motor may fail under heavy load, while an expensive one might be overkill for lighter tasks. Careful evaluation is essential. Users must ask themselves: does the motor meet my standard without compromise? Reflecting on these aspects can guide better decision-making in choosing the right 7 RPM motor.

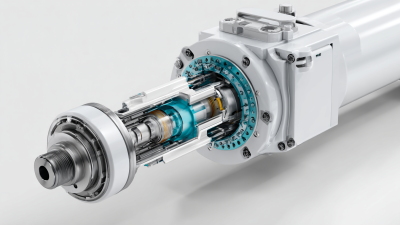

Innovations in 7 RPM motor technology are set to reshape various industries by 2026. As demand for energy-efficient and compact solutions grows, manufacturers are adopting advanced materials. Lightweight composites provide strength while reducing overall mass. These materials enhance thermal stability, enabling motors to perform better under varying conditions. When motors are lighter, they become more versatile and adaptable.

The future also sees the rise of smart motors. These motors integrate IoT technology, allowing for real-time monitoring and data analytics. Users can track performance metrics efficiently. However, there are challenges with security and data privacy. Companies must prioritize safe data handling while innovating. Additionally, ensuring compatibility with existing systems may complicate integration.

Even with these advancements, there remain areas for improvement. Current designs may still lack sufficient energy efficiency for certain applications. This gap highlights the need for ongoing research. Innovators should focus on enhancing motor longevity and reducing maintenance needs. Continuous iteration and feedback from users can lead to better outcomes in future designs.