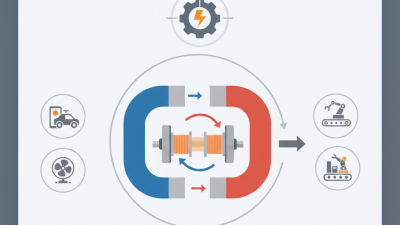

In the quest for optimized performance and efficiency, selecting the right Motor Type is crucial. According to the International Energy Agency (IEA), electric motors account for approximately 45% of global industrial electricity consumption. This statistic underscores the need for advanced motor technologies that enhance operational productivity while minimizing energy use.

Recent studies predict a significant shift towards more efficient motor types by 2026. For instance, variable speed drives (VSD) can improve efficiency by up to 60% compared to fixed-speed motors. However, the transition is not always straightforward. Industries still rely heavily on older technologies due to familiarity and initial costs. The reluctance to change often impedes progress.

Moreover, advancements in materials and design impact motor performance. Companies are increasingly exploring permanent magnet motors and synchronous designs. Yet, challenges persist in terms of scalability and integration into existing systems. As industries evolve, understanding the nuances of each Motor Type will become essential for sustainable growth.

As we approach 2026, motor technology is evolving rapidly. High-efficiency motors are becoming standard. Data indicates that the market for electric motors is projected to reach $191 billion by 2026. This growth is driven by advanced materials and innovative designs that enhance performance. Efficiency gains are essential for various industries, leading to reduced energy costs.

Recent studies show that adopting permanent magnet motors can increase efficiency by up to 30%. These motors generate more power while consuming less energy. Engineers are exploring different winding techniques, too. For example, concentrated windings are gaining traction. They can reduce copper losses, which is a major efficiency killer in traditional motors.

However, challenges remain. Not all applications benefit equally from high-efficiency motors. Some situations require trade-offs between cost and performance. Organizations must analyze their needs carefully. Deployment of advanced motors can also introduce complexities in manufacturing and maintenance. It is crucial to evaluate the long-term implications of these technologies on operational efficiency. Navigating this landscape requires both caution and innovation.

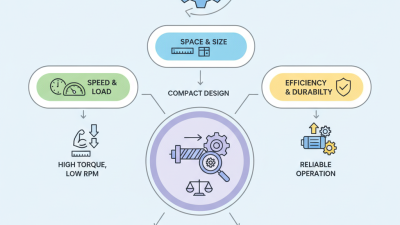

Choosing the best motor type in 2026 depends on several key performance indicators. Efficiency is paramount. Recent reports indicate that electric motors can achieve 95% efficiency. In contrast, traditional motors often peak around 90%. This difference directly impacts energy consumption and operating costs.

Torque-to-weight ratio is another essential factor. Motors that deliver higher torque with less weight are preferable. Innovative designs are pushing boundaries, often reaching industry averages of 3 Nm/kg. These advancements enhance performance without compromising stability.

Tips: Evaluate your application’s specific needs. Consider load conditions carefully. An oversized motor can waste energy and create unnecessary costs.

Another factor is heat dissipation. Efficient cooling systems extend motor lifespan. Controlling operating temperature is vital, especially in demanding environments. Reports highlight a reduction in performance due to inadequate cooling.

Regular maintenance cannot be overlooked. Inspections and adjustments prevent issues that could compromise efficiency. Reflecting on these factors will lead to a more informed choice for optimized performance in 2026.

This chart displays the key performance indicators (KPIs) for various motor types in 2026, focusing on efficiency and power output. The motor types considered include Brushless DC Motors, Induction Motors, and Stepper Motors.

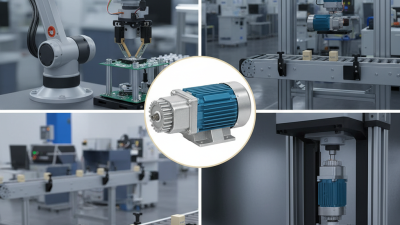

As we enter 2026, the choice between brushless and brushed motors becomes critical. Brushless motors offer higher efficiency and longer lifespans. They require less maintenance and generate less heat during operation. This makes them ideal for applications requiring durable performance.

On the other hand, brushed motors present a more straightforward design and lower initial costs. They can excel in environments where simplicity is key. However, they may require more frequent replacements. Their performance can degrade over time, leading to inefficiencies.

Both motor types have their pros and cons. Brushless motors may seem superior, but they can be more complex to control. Brushed motors, while easier to manage, could end up costing more in the long run. Finding the right balance between performance and cost efficiency is essential for optimized use. Every application demands careful consideration of these factors.

| Motor Type | Efficiency (%) | Torque (Nm) | Weight (kg) | Maintenance Frequency | Cost ($) |

|---|---|---|---|---|---|

| Brushed Motor | 75 | 0.5 | 1.2 | Frequent | 50 |

| Brushless Motor | 90 | 0.8 | 0.9 | Rare | 100 |

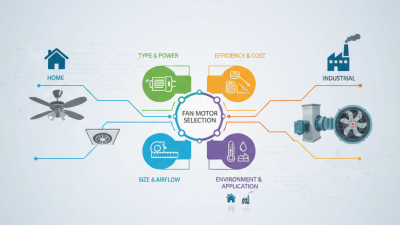

Energy efficiency standards are evolving rapidly, and their influence on motor selection is significant. As we approach 2026, industries must adapt to stricter regulations. These standards aim to reduce energy consumption and greenhouse gas emissions. Organizations increasingly prioritize efficiency over raw power. This shift influences the types of motors that are considered optimal for various applications.

The impact of these standards is profound. Motors with higher efficiency ratings are becoming the norm. However, not every motor marketed as efficient truly lives up to expectations. Some may underperform in real-world conditions. Industry professionals must evaluate motors beyond labels. They need to consider operational demands and specific usage scenarios.

A common oversight is neglecting maintenance practices that optimize motor performance. Users might install the latest technology but fail to maintain it properly. This inconsistency leads to subpar results. Beyond energy use, it’s crucial to measure the long-term costs involved. Investing in an efficient motor may save money, but initial costs can deter some users. Balancing these factors will be essential in making informed decisions by 2026.

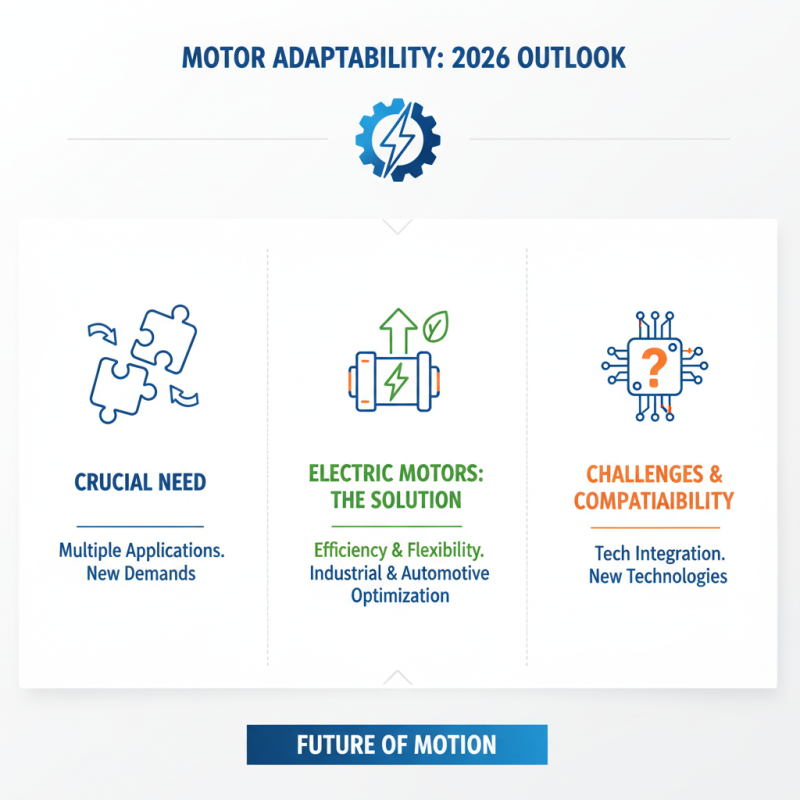

As we look toward 2026, the adaptability of motor types becomes crucial. Multiple applications will emerge, requiring motors that can adjust to new demands. Electric motors are a prime candidate because they offer both efficiency and flexibility. They can be optimized for various environments, from industrial to automotive sectors. However, there are challenges; compatibility with new technologies is vital.

Synchronous motors, for instance, may excel in precision but face limitations with energy fluctuations. We need to assess whether they can meet the upcoming standards. Moreover, the rise of smart automation raises questions. Can traditional motors align with advanced control systems? Many thoughts remain on how to bridge this gap effectively.

The balance between performance and efficiency is delicate. While some motor types promise higher outputs, they may also increase energy consumption. This contradiction calls for a deeper look. In 2026, understanding this interplay will be key to future-proofing motor types. Embracing change is essential, but it requires careful reflection on what works best now and in the future.