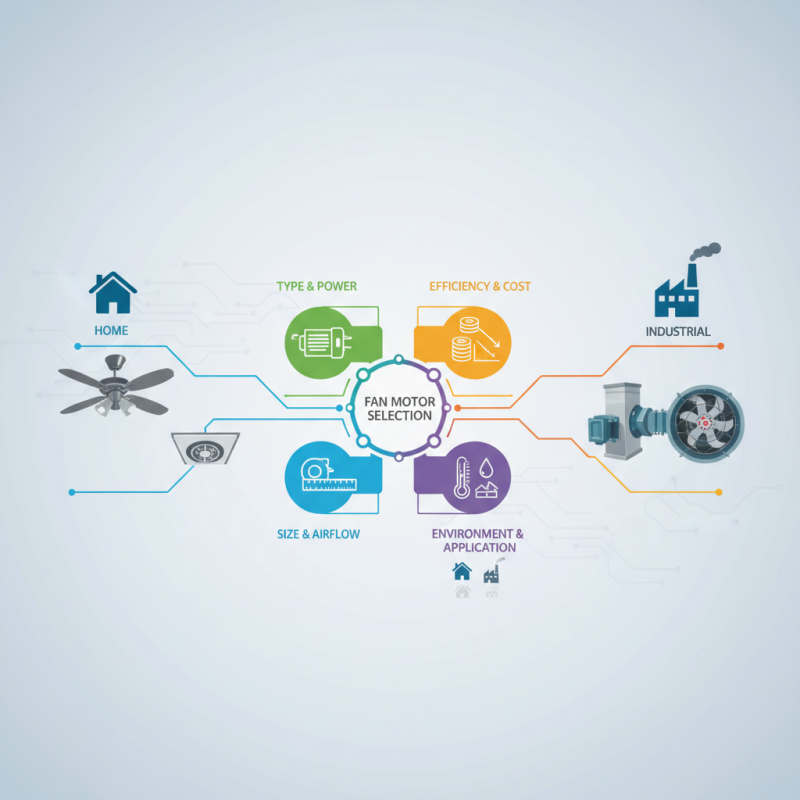

Choosing the right fan motor for your home or industrial needs is crucial for ensuring efficiency, performance, and longevity. As an integral component of various ventilation and air circulation systems, the fan motor plays a significant role in both comfort and functionality. According to industry expert John Smith, a renowned specialist in HVAC systems, "Selecting the appropriate fan motor can transform the efficiency of your cooling or heating system, ultimately affecting your energy costs and indoor air quality."

When evaluating fan motors, it’s essential to consider several factors, including the type of motor, size, power requirements, and specific applications. Whether you're looking to install a ceiling fan, exhaust system, or industrial ventilation setup, understanding these parameters can lead to better performance and reduced operational costs.

This article will guide you through the essential criteria for selecting the ideal fan motor, providing insights that will help you make informed decisions to meet both residential and industrial needs. By delving into the intricacies of fan motor selection, you will be equipped to enhance your space’s climate control while maximizing energy efficiency.

When choosing the right fan motor for your home or industrial needs, it's essential to start with a clear understanding of your specific requirements. For home use, factors such as room size, expected airflow (measured in cubic feet per minute or CFM), and energy efficiency play crucial roles. According to the American Council for an Energy-Efficient Economy (ACEEE), using energy-efficient fan motors can reduce energy consumption by up to 50%, making them a sustainable choice for residential spaces. Selecting an appropriate fan motor based on these parameters not only enhances comfort but also contributes to significant savings in energy costs over time.

In contrast, industrial needs demand a more robust assessment. Industrial fan motors typically need to handle heavier workloads and may require features such as variable speed control to accommodate fluctuating demands. The global fan motor market is projected to reach $19 billion by 2027, driven by advancements in technology and growing industrial applications. As reported by Research and Markets, the demand for high-performance electric motors is increasing, which directly impacts fan motor specifications, including insulation class and operating temperature range. Understanding these parameters ensures that you choose a fan motor capable of performing efficiently under strenuous conditions, ultimately leading to improved operational reliability in industrial settings.

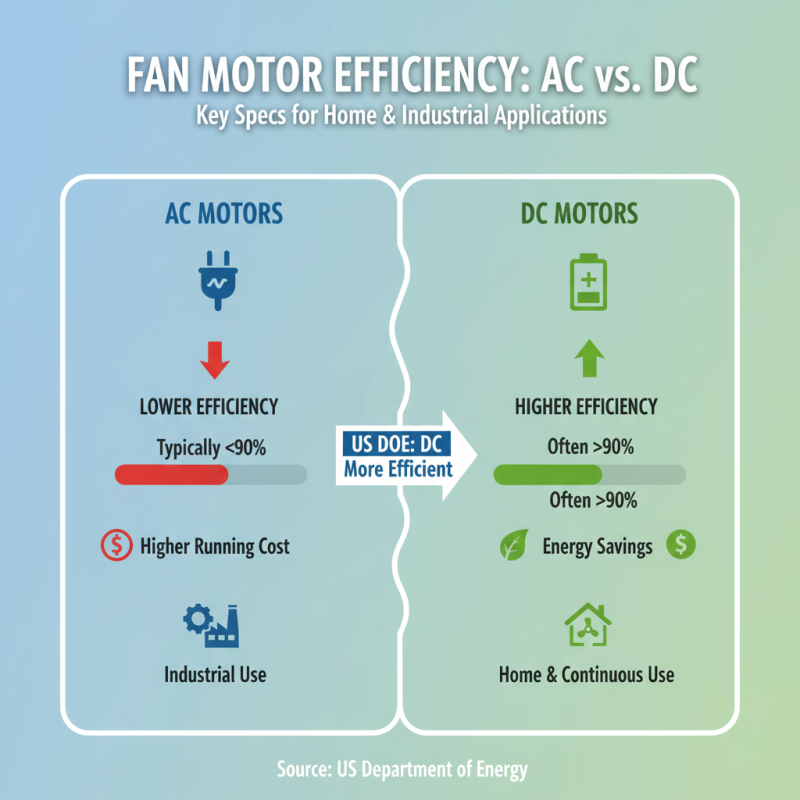

When selecting a fan motor, understanding the different types and their applications is crucial for meeting your specific home or industrial needs. There are primarily two categories of fan motors: AC (Alternating Current) and DC (Direct Current). AC motors, commonly used in residential settings, are notable for their durability and efficiency in high-voltage applications; they often power ceiling fans and exhaust systems. In contrast, DC motors are favored in situations requiring variable speed options and higher energy efficiency. Industry studies indicate that DC motors can achieve energy savings of up to 30% compared to their AC counterparts, making them ideal for residential use in areas such as HVAC systems.

In industrial environments, the choice of fan motor often hinges on specific applications. Permanent split capacitor (PSC) motors are prevalent in ventilation systems due to their reliability, while shaded pole motors are typical for smaller fans. In settings that require heavy-duty applications, such as manufacturing plants, high-efficiency motors compliant with NEMA Premium standards are encouraged, as they help to diminish energy consumption by approximately 8% over standard motors, according to the U.S. Department of Energy. This energy efficiency translates not only into cost savings but also contributes to sustainability efforts in industrial operations. Thus, selecting the appropriate fan motor type based on the setting is essential for optimizing performance and reducing operational costs.

| Type of Fan Motor | Application | Power Source | Efficiency Rating | Typical RPM |

|---|---|---|---|---|

| AC Fan Motor | Home Ventilation, Ceiling Fans | AC Power | Up to 85% | 1200-1800 RPM |

| DC Fan Motor | Computers, Small Appliances | DC Power | Up to 90% | 2000-4000 RPM |

| EC Fan Motor | HVAC Systems, Industrial Fans | EC Power | Up to 95% | 1200-3000 RPM |

| Brushless DC Motor | Medical Equipment, Robotics | DC Power | Up to 92% | 1500-6000 RPM |

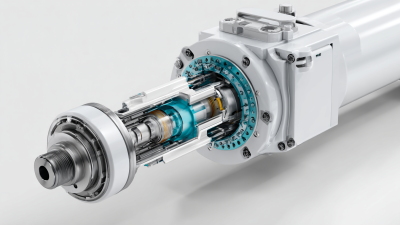

When selecting a fan motor for either home or industrial applications, there are several critical specifications to consider that can significantly impact performance and energy efficiency. Firstly, the motor type—whether it’s AC or DC—can affect both operational cost and energy consumption. According to the U.S. Department of Energy, DC motors typically display higher efficiency than their AC counterparts, often exceeding efficiencies of 90%, which can lead to considerable energy savings over time, especially in continuous operation scenarios.

Another key specification is the motor's power rating, usually measured in horsepower or watts. The appropriate power rating is crucial; too weak a motor may underperform, while an excessively powerful motor can lead to wasted energy and increased operational costs. Data from the International Energy Agency indicates that accurately sized motors can operate at optimal efficiency levels, resulting in energy savings of up to 20%. Additionally, considering aspects such as rotational speed (RPM), torque, and duty cycle helps in determining motor suitability for specific applications, especially in industrial environments where demands may fluctuate.

Lastly, it's essential to evaluate the environmental conditions in which the fan motor will operate. Factors such as ambient temperature, humidity, and exposure to dust or corrosive agents can influence the lifespan and reliability of a motor. For instance, motors operating in high-temperature environments may require specific insulation classes to prevent overheating. Adhering to these specifications not only ensures compliance with industry standards but enhances the longevity and performance of the fan system overall.

When selecting a fan motor, energy efficiency and performance are critical factors that can significantly impact both the environment and your utility bills. Different types of fan motors, such as AC and DC motors, offer varying levels of energy consumption and operational efficiency. Generally, DC motors tend to be more energy-efficient, as they utilize electronic speed controllers that minimize power loss and adjust speed according to demand. This results in lower energy consumption over time, making them a favorable choice for both residential and industrial applications.

On the other hand, traditional AC motors can provide robust performance and reliability, particularly in heavy-duty environments where high airflow is required consistently. However, their energy efficiency can be lower, especially if operated at speeds that exceed the optimal range for the given application. It's essential to consider factors such as the motor's efficiency rating, the operational environment, and the load requirements when making a choice. Ultimately, balancing energy efficiency with performance needs is crucial for ensuring long-term satisfaction with your fan motor selection.

When selecting a fan motor for either home or industrial applications, proper installation is crucial for maximizing performance. According to a report by the International Electrotechnical Commission (IEC), an estimated 30% of motor failures result from improper installation. This highlights the importance of following manufacturer guidelines and ensuring that the motor is mounted securely, aligned correctly, and connected to the appropriate power supply. For industrial settings, using vibration analysis tools can further enhance installation quality by identifying any misalignments that may lead to premature wear.

Maintenance is equally critical for sustaining optimal fan motor efficiency. A study published in the Journal of Mechanical Science and Technology indicates that regular maintenance can improve motor lifespan by up to 50%. Key practices include checking and cleaning air filters to prevent dust accumulation, which can hamper airflow and increase energy consumption. Additionally, lubricating moving parts and inspecting electrical connections periodically help reduce operational headaches and ensure the system runs smoothly.

Maintaining a clear maintenance schedule and keeping comprehensive records of service activities not only prolongs the life of the fan motor but can also lead to significant cost savings in energy bills and repair costs over time.