When it comes to selecting the right motor for your next project, one option that stands out is the 7 RPM motor. Renowned expert in motion control systems, Dr. Emily Tran, states, "The choice of motor speed can significantly influence the efficiency and performance of an application." With its precise speed control and adaptability, the 7 RPM motor has become a favored choice across various industries, including automation, robotics, and material handling.

The fundamental advantage of a 7 RPM motor lies in its ability to provide consistent and reliable performance, essential for tasks requiring a steady output. This motor speed is particularly beneficial in applications such as conveyor systems and slow-moving mechanisms, where efficiency is paramount. Moreover, as more industries recognize the importance of energy savings and optimal performance, the demand for 7 RPM motors has surged.

Investing in a 7 RPM motor not only ensures that projects run smoothly but also positions you at the forefront of technological advancements. As we delve deeper into the myriad benefits and diverse applications of the 7 RPM motor, it becomes clear why making this choice is crucial for modern engineering endeavors.

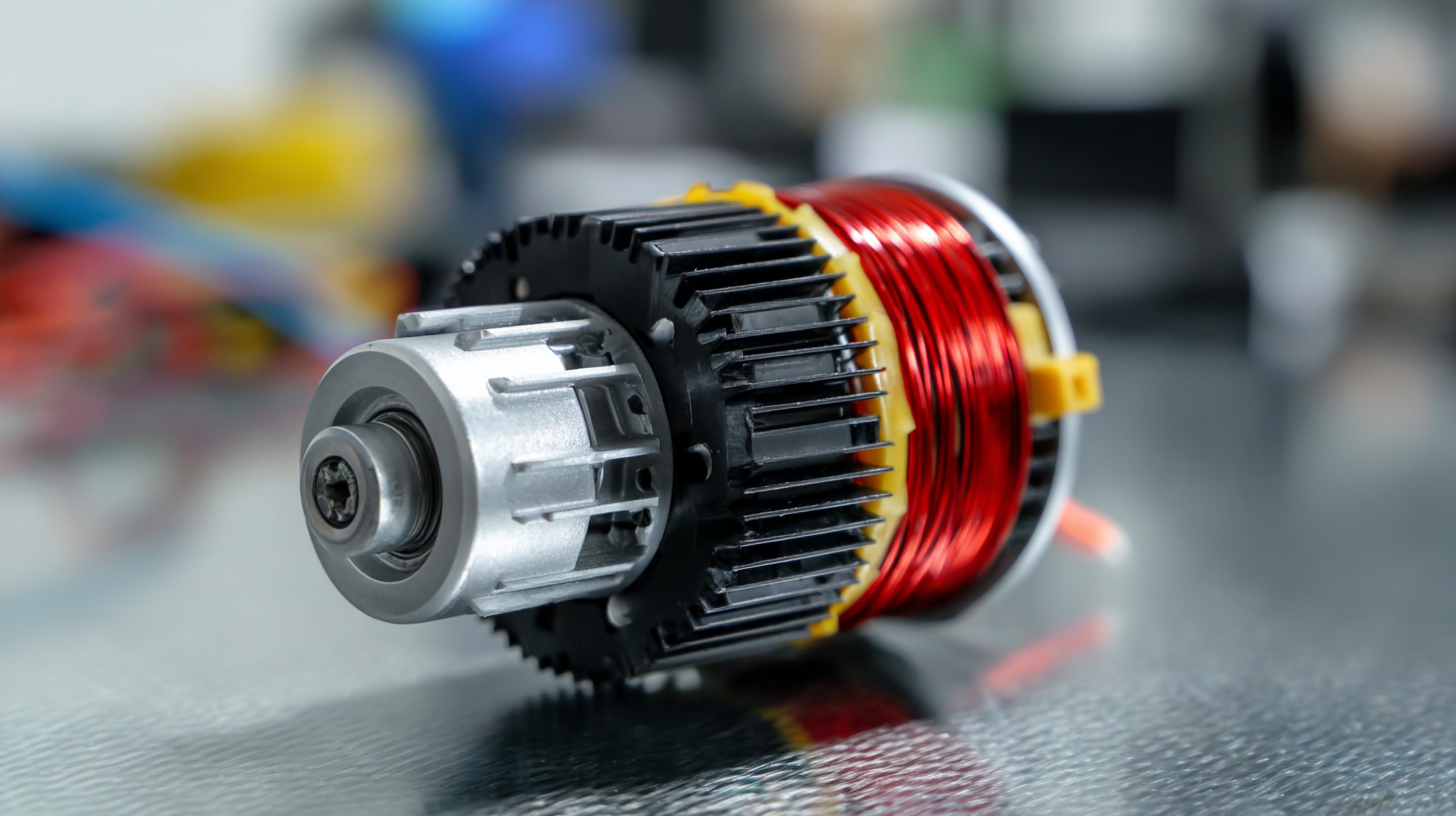

When considering the power needs of your next project, a 7 RPM motor can offer distinct advantages that set it apart in various applications. One key benefit is its exceptional torque output at low speeds, making it ideal for heavy-duty tasks. This feature is particularly advantageous in industrial machinery, where consistent and reliable performance is essential for processes such as conveyor systems or mixing applications. The controlled speed also reduces wear and tear on components, ultimately leading to lower maintenance costs and longer service life.

Another significant advantage of utilizing a 7 RPM motor lies in its energy efficiency. Operating at a lower speed allows for optimized energy consumption while maintaining effective torque, which can be a major cost saver in operations that run continuously. This motor speed is especially suitable for applications in robotics or automated systems, where precision and energy efficiency are crucial. Furthermore, the ability to work efficiently with a variety of load conditions enhances the motor’s versatility, making it an excellent choice for both industrial setups and DIY projects.

When considering the ideal applications for 7 RPM motors across various industries, their unique attributes come into play. The low rotational speed of 7 RPM is particularly beneficial in situations requiring precise control and smooth operation. These motors excel in applications such as conveyor systems in manufacturing, where consistent speed is crucial for maintaining product integrity, as well as in robotics where careful movement is essential to avoid damaging sensitive components.

In the healthcare sector, 7 RPM motors find their applications in medical devices such as automated drug dispensers and patient beds, where reliability and precision are paramount. Additionally, in the entertainment industry, these motors are used in animatronics and special effects where controlled movements create a seamless experience for audiences.

The versatility and efficiency of 7 RPM motors make them a valuable asset across diverse sectors, enabling improved functionality and enhanced operational performance in projects.

When considering the right motor for industrial applications, the choice between a 7 RPM motor and high-speed alternatives can significantly impact both efficiency and effectiveness. While high-speed motors are designed for rapid operations, they often introduce challenges such as increased heat generation, higher wear and tear, and greater energy consumption. Conversely, a 7 RPM motor provides a steady and controlled output, making it ideal for processes that require precision and reliability, such as conveying or mixing applications.

**Tips:** When selecting a motor for your project, evaluate the specific requirements of your application. If the task demands precise control and longevity, a 7 RPM motor is likely the best fit. Additionally, consider the potential cost savings in maintenance and energy efficiency offered by lower RPM motors over time.

Moreover, the durability of 7 RPM motors can be a significant advantage in heavy-duty applications. Their slower operation not only reduces stress on mechanical components but also prolongs the lifespan of the motor itself. This translates to lower replacement costs and less downtime. High-speed motors may be appropriate for applications that demand rapid movement, but their maintenance and operational costs can escalate quickly in the long run.

**Tips:** Always account for duty cycles and load requirements when choosing your motor. An improperly matched high-speed motor can lead to inefficiencies or even equipment failure, while a 7 RPM motor can offer optimal performance without unnecessary complications.

Choosing the right motor for your project can significantly impact its efficiency and performance, and 7 RPM motors are becoming increasingly popular due to their remarkable energy efficiency. According to a report by the International Energy Agency (IEA), low-speed motors can reduce energy consumption by up to 25% compared to their higher RPM counterparts. This reduction not only lowers operating costs but also minimizes the environmental footprint of operations, aligning with global sustainability goals.

In applications such as conveyor systems and material handling, 7 RPM motors demonstrate exceptional performance. Their design enables smoother operation and reduced wear on components, facilitating longer service life and lower maintenance costs. A study from the Department of Energy highlights that using lower speed motors can decrease mechanical stress, contributing to a failure rate reduction of approximately 15% over traditional motors. This is crucial in sectors like manufacturing and logistics, where reliability and efficiency are paramount to maintaining productivity. Investing in 7 RPM motors is a strategic choice that can yield substantial long-term benefits in energy savings and operational effectiveness.

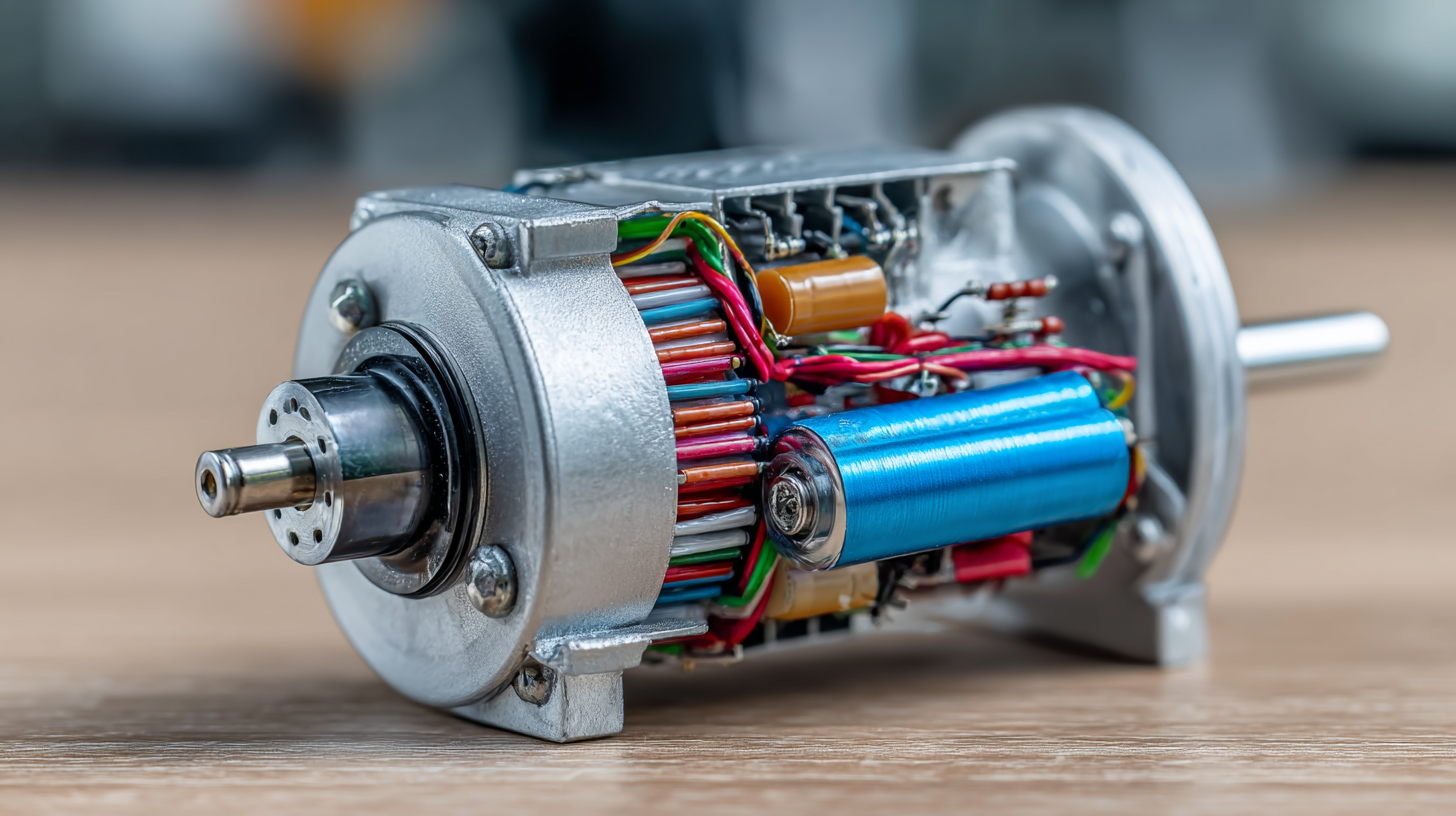

When opting for a 7 RPM motor for your project, it is essential to consider installation and maintenance aspects to ensure optimal performance. According to a report by the Electric Motor Association, motors operating at lower speeds, such as 7 RPM, typically require robust mounting solutions to handle the increased torque load they produce. Proper alignment during installation helps prevent excess wear on bearings and gears, ultimately extending the lifespan of the motor. Utilizing vibration-dampening mounts can also mitigate potential issues that might arise from prolonged operation.

Maintenance for 7 RPM motors should prioritize regular inspections and lubrication as part of a preventive strategy. The Institute of Electrical and Electronics Engineers recommends routine checks every six months, focusing on electrical connections, bearing conditions, and lubrication levels. According to recent industry data, a well-maintained motor can achieve efficiency rates of up to 95% over its lifecycle. This efficiency, combined with the low speed, makes it crucial to keep the motor clean and free from debris to maintain an optimal operating environment, ensuring reliability across various applications, from conveyor belts to agricultural equipment.

This bar chart illustrates the key benefits of choosing a 7 RPM motor for your next project. Each bar represents a different advantage, showcasing how these motors excel in energy efficiency, cost-effectiveness, and more, making them an excellent choice for various applications.