Choosing the right worm motor for your project can be a daunting task. According to John Smith, a leading expert in the worm motor industry, “Selecting the wrong motor can derail your entire project.” His insight highlights the importance of careful evaluation.

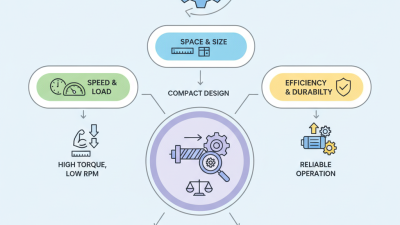

Worm motors are not all the same. They vary in size, torque, and speed. Understanding your project's specific needs is crucial. For instance, a small robotic application might require a different motor than a large conveyor system. Striking the right balance can often be challenging.

Many people overlook details when selecting a worm motor. Aspects like mounting options or backlash can greatly impact performance. This can be a painful lesson. By taking the time to research, you can avoid costly mistakes. Each component in a project deserves attention, especially the worm motor.

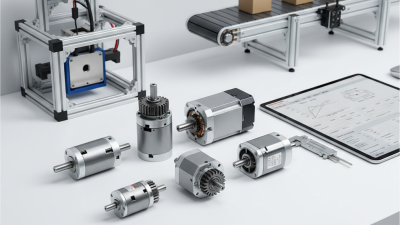

Worm motors are unique devices known for their ability to provide high torque and slow speed. They consist of a worm gear and a worm wheel. This design offers a mechanical advantage, making them ideal for applications requiring a large reduction ratio. Worm motors can come in various types, including inline and parallel shaft configurations, each serving different needs.

Choosing the right worm motor can be confusing. Consider the load requirements of your project. Higher torque means heavier loads, while speed influences application efficiency. Not every worm motor will be suited for every task. Some may not handle continuous operations well.

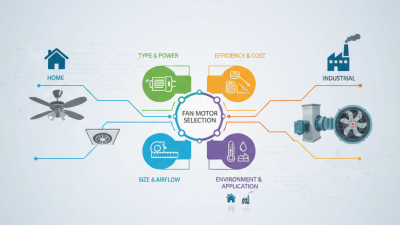

**Tips:** Always evaluate the operational environment. High temperatures or humidity can affect motor performance. Additionally, ensure the motor can fit within your design specifications. Different motors may have varying efficiency ratings. Understanding these details can save time and money. Don't overlook the importance of quality materials. They can impact durability and functionality in the long run.

When selecting a worm motor for your project, it’s vital to focus on key specifications. These specifications directly impact performance and suitability. Look at the torque rating first. Higher torque ratings indicate a motor can handle greater loads. This is crucial for applications involving heavy machinery.

Another important factor is the gear ratio. A high gear ratio provides more torque but less speed. Conversely, a low gear ratio gives higher speed with reduced torque. It's essential to evaluate the balance between these two aspects based on your application needs.

Tip: Always consider the environment where the motor will operate. Factors like temperature and humidity can affect motor performance.

Don’t overlook the power supply requirements. Check if the motor needs AC or DC power and its voltage. This will help avoid compatibility issues later on. Remember, even small details can lead to significant problems. Do some testing if possible. It’s better to find discrepancies before full-scale use.

When selecting a worm motor, understanding torque and speed is essential. Torque tells you how much force the motor can exert. For projects requiring heavy lifting, higher torque is crucial. If your application is lightweight, you may not need as much. It’s about matching these requirements.

Speed is another critical factor. While some projects need fast movement, others require precision. Consider how quickly you need your motor to turn. Sometimes, speed can compromise torque. Finding a balance is not always straightforward. It’s easy to think a high-speed motor is superior, but that could lead to issues in heavier applications.

Analyzing your project's unique demands helps clarify your choices. Create a checklist of required speeds and torque. It can be challenging to get these numbers just right. Mistakes in estimation often occur, so it’s wise to revisit your calculations. Testing different configurations may lead to unexpected insights. This iterative process can be time-consuming but is invaluable for optimal performance.

When selecting a worm motor, material durability is crucial. Different materials offer varying resistance to wear and degradation. For instance, metals like steel provide strength but may corrode over time if not treated properly. Plastic components can be lighter and resistant to corrosion but may wear out faster under high loads. It's essential to consider the operating environment. If moisture or contaminants are present, a more durable material is required.

Efficiency is another key factor. Higher efficiency means less energy loss during operation. A motor with lower friction and heat generation tends to have better performance. Unfortunately, achieving high efficiency often requires careful selection of materials and design. Some motors might perform well initially but degrade quicker than expected. Users should analyze long-term operational costs versus initial purchase price. Sometimes, choosing a seemingly cheaper option leads to more issues later.

Pay attention to specific requirements of your project. Consider load capacity, speed, and operational conditions. While it might be tempting to pick the first option, reflection is necessary. Test different configurations and assess their impact on your project’s efficiency and durability. Sometimes, the best solution means going beyond the obvious choices.

When selecting a worm motor for your project, consider its integration with existing systems. Compatibility is crucial. Ensure the motor’s shaft size matches your design. Incorrect dimensions can lead to performance issues.

Also, pay attention to the power requirements. Does your existing power supply meet the worm motor's needs? A mismatch could cause inefficiencies. Think about how the motor will connect to other components. You may need adapters or couplings.

Don’t forget about the mounting options. Some motors offer flexible mounting styles, while others are more rigid. Assess whether your design can accommodate these variations. Review any limitations in your design process to avoid complications. Sometimes, the best solution isn't the most expensive one, but rather the one that fits seamlessly and operates reliably within your setup.