Choosing the right gear motor for your project is crucial to ensure optimal performance, efficiency, and reliability. A gear motor, which combines a motor with a gear reduction system, can significantly enhance the capabilities of your machinery by providing higher torque and lower speed, making it an essential component in various applications ranging from robotics to conveyor systems. However, with a plethora of options available in the market, selecting the most suitable gear motor can be a daunting task.

In this comprehensive guide, we will explore the key factors you need to consider when selecting a gear motor for your specific needs. From understanding the required torque and speed to evaluating efficiency and mounting options, this guide will help you navigate through the technical specifications and make an informed decision. Whether you're a seasoned engineer or a DIY enthusiast, having a clear understanding of your project requirements and how different gear motors can fulfill them will ultimately lead to a successful application. Get ready to delve into the essential aspects of gear motors to empower your project with the right power transmission solution.

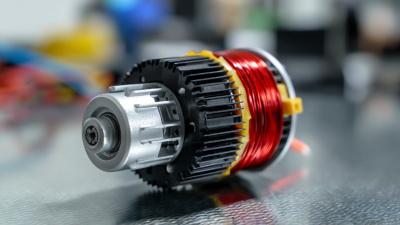

Gear motors are essential components in various applications, providing a combination of torque and speed control. Understanding the different types of gear motors and their specific applications can guide you in selecting the most suitable motor for your project. The two primary types of gear motors are DC gear motors and AC gear motors. DC gear motors are preferred for battery-operated devices and smaller-scale applications due to their simplicity and ease of control. In contrast, AC gear motors tend to be used in larger systems, where they can deliver consistent power and efficiency.

In addition to the motor type, the application plays a crucial role in choosing the right gear motor. For instance, robotic systems often require gear motors that offer high precision and responsiveness. In conveyor systems, gear motors must provide sufficient torque to handle varying loads while maintaining a steady speed. Furthermore, applications like automotive and industrial equipment may necessitate gear motors that can withstand harsh environments and provide reliable performance under stress. Analyzing your project requirements and understanding these fundamental distinctions will help streamline the selection process and ensure optimal performance.

When selecting a gear motor for your project, several key factors must be taken into account to ensure optimal functionality and efficiency. First, consider the torque requirements. According to industry reports, about 60% of gear motor failures are related to mismatched torque specifications. Assess the load characteristics of your application, measuring the starting and running torque needed for your motor to perform effectively. It's crucial to choose a motor that not only meets but exceeds your torque requirements to accommodate variations in load.

Another significant factor is the motor speed. The relationship between speed and torque is critical; often, a lower speed can provide higher torque output, which can be beneficial for certain applications. Make sure to calculate the necessary RPM for your project's needs. Data indicates that 75% of user-reported issues stem from improper speed selections. Utilizing a gear ratio suited to your application's requirements can optimize performance.

Tips: Always consult torque vs. speed curves provided in the motor datasheets to visualize how different gear ratios affect performance. Moreover, consider the operational environment—factors such as temperature, dust, and moisture can significantly influence motor choice. Adequate protection ratings should be prioritized, especially for outdoor or harsh condition applications. Lastly, don’t underestimate the importance of efficiency ratings; choosing a motor with higher efficiency can lead to significant cost savings over time due to reduced energy consumption.

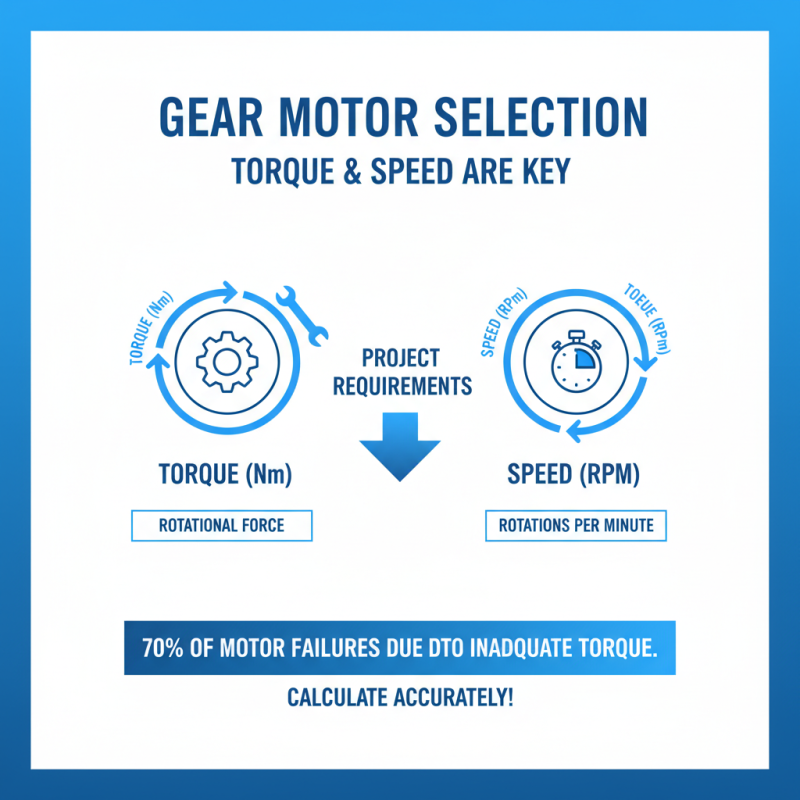

When choosing the right gear motor for your project, evaluating torque and speed requirements is paramount. Torque, measured in Newton-meters (Nm), reflects the motor's ability to exert rotational force, while speed, usually expressed in revolutions per minute (RPM), indicates how quickly the motor can complete rotations. A comprehensive study from the Electric Motors and Drives Journal indicates that about 70% of motor failures are due to inadequate torque specifications, making it critical to calculate your torque requirements accurately based on the load and dynamics of your application.

Consider a few key aspects when assessing torque and speed needs. First, calculate the load the motor will be moving and any additional friction or resistance it will encounter. For applications requiring variable speed, a motor that offers a broad range of speed adjustments may be necessary. According to the International Electromechanical Industry Association, applications spanning from robotics to conveyor systems generally benefit from motors that can provide a torque-to-speed ratio tailored to specific operational challenges.

Tips: Always refer to the motor's torque-speed curve when selecting your gear motor. This graph provides visual insight into how the motor operates across different speeds and loads. Additionally, overestimating speed requirements can lead to inefficient energy use; aim for a balance that doesn't excessively exceed operational demands. Regularly revisiting these metrics during project stages can prevent late-stage adjustments and ensure optimal performance.

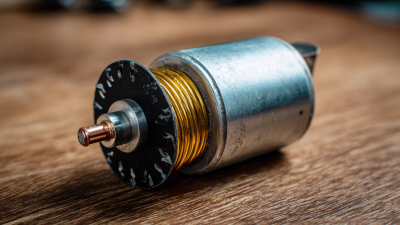

When selecting the right gear motor for your project, assessing size and weight constraints is crucial. A well-known industry report by the International Journal of Advanced Manufacturing Technology highlights that the weight of a gear motor can significantly impact the overall efficiency and performance of a system. For instance, lighter gear motors often enable more compact designs and increased mobility, making them suitable for applications such as robotics and portable equipment. As designs evolve to become smaller and more intricate, the demand for gear motors weighing less than 10 kg continues to rise, with projections indicating a market growth of about 6.5% annually in the lightweight segment through 2025.

Moreover, size specifications play a critical role in compatibility with existing systems and assemblies. According to a study published in the Journal of Mechanical Engineering, the physical dimensions of gear motors can affect torque transmission and operational stability. To optimize performance, engineers must balance the size of the gear motor with its torque capability and operational speed. It's essential to consider that choosing a gear motor that fits within the project's designated spatial constraints while still delivering the required power output can be a challenging task; therefore, detailed calculations and simulations should be performed to ensure the selected motor aligns with the design's physical and functional requirements.

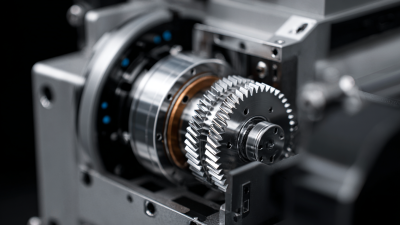

When selecting a gear motor for your project, considering additional features and customization options can greatly enhance the performance and compatibility of the motor with your specific application. One key feature to evaluate is the gear ratio. Different gear ratios can vastly affect the torque and speed of the motor, making it essential to choose one that aligns with your project requirements. Additionally, gear motors can come with options such as brake systems, which are particularly useful in applications requiring precise positioning, or feedback systems that provide real-time data on motor performance.

Customization options provide further flexibility in adapting gear motors to meet specific project needs. For instance, environmental considerations, such as temperature and humidity, might necessitate selecting materials that can withstand harsh conditions. Custom shaft configurations or mounting options can also be tailored to fit unique installation spaces, making it easier to integrate the motor into existing systems. Moreover, adjustments in electrical specifications like voltage or phase can ensure optimal performance within your project’s electrical framework. By paying attention to these additional features and customization options, you can select a gear motor that not only meets but exceeds your project’s expectations.

This bar chart displays the key specifications for selecting a gear motor for your project, including torque, speed, power, size, and weight. Understanding these specifications can help in choosing the right gear motor to meet your project's requirements.