As we step into the future, the realm of Elc Motors is poised for transformative advancements that promise to reshape the landscape of automotive technology. The ongoing evolution in electric motor design and efficiency is not only paving the path for greener and more sustainable transportation but also enhancing the capabilities of various applications in industries ranging from automotive to aerospace. In 2025, we will witness groundbreaking trends in Elc Motors, driven by innovations in materials, control systems, and energy management, setting new benchmarks for performance and reliability.

In this dynamic environment, various technological innovations are expected to come to the forefront. The integration of artificial intelligence and machine learning into Elc Motors will optimize operations, enabling smarter energy consumption and predictive maintenance, which are paramount for enhancing overall efficiency. Moreover, advancements in lightweight materials promise to further enhance the performance of electric motors, making them more efficient and effective for a wide range of uses. As these trends unfold, industry stakeholders will need to navigate the challenges and opportunities presented by these innovations, ensuring that they remain at the cutting edge of technology in the fast-evolving world of Elc Motors.

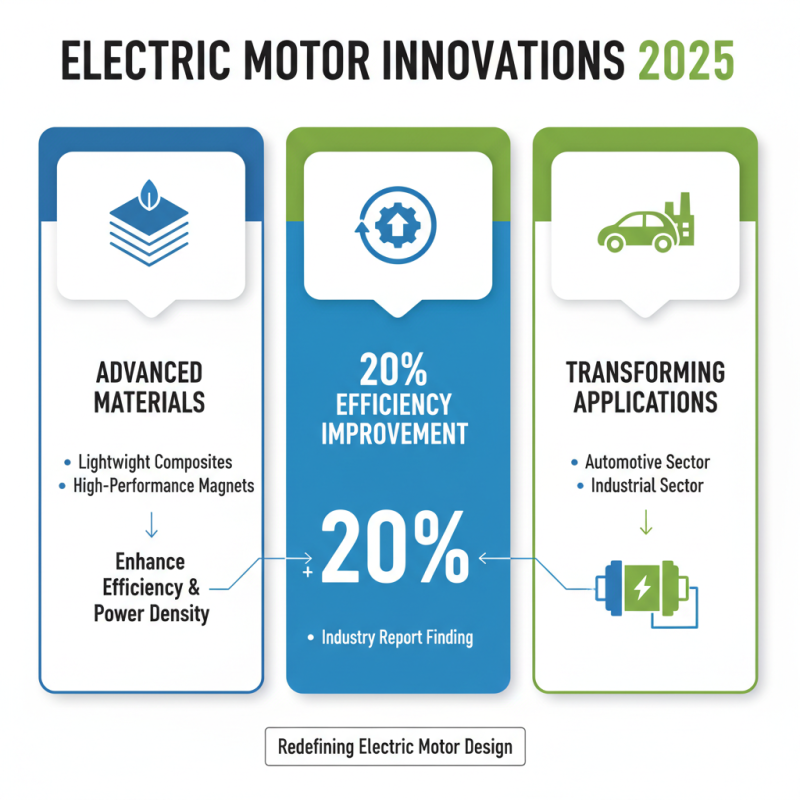

As the electric motor industry continues to evolve, 2025 promises to bring groundbreaking innovations and technologies that will redefine electric motor design. One of the most significant trends is the integration of advanced materials, such as lightweight composites and high-performance magnets, which enhance efficiency and power density. According to a recent industry report, using these materials can improve electric motor efficiency by up to 20%, a substantial leap that could transform applications in automotive and industrial sectors.

Additionally, the rise of smart motors equipped with IoT capabilities is creating new avenues for monitoring and optimization. These smart motors can collect real-time data on performance and energy consumption, allowing for predictive maintenance and energy management. A study from a leading energy analytics firm predicts that by 2025, over 30% of electric motors will feature such connectivity, significantly reducing downtime and operational costs for businesses.

Tips: To stay ahead in the rapidly changing landscape of electric motor technology, organizations should invest in training their workforce on emerging smart technologies. Additionally, collaborating with research institutions can foster innovation and lead to the development of next-generation motor designs that align with sustainability goals. Keeping abreast of industry standards and regulations will also be vital for leveraging new technologies effectively.

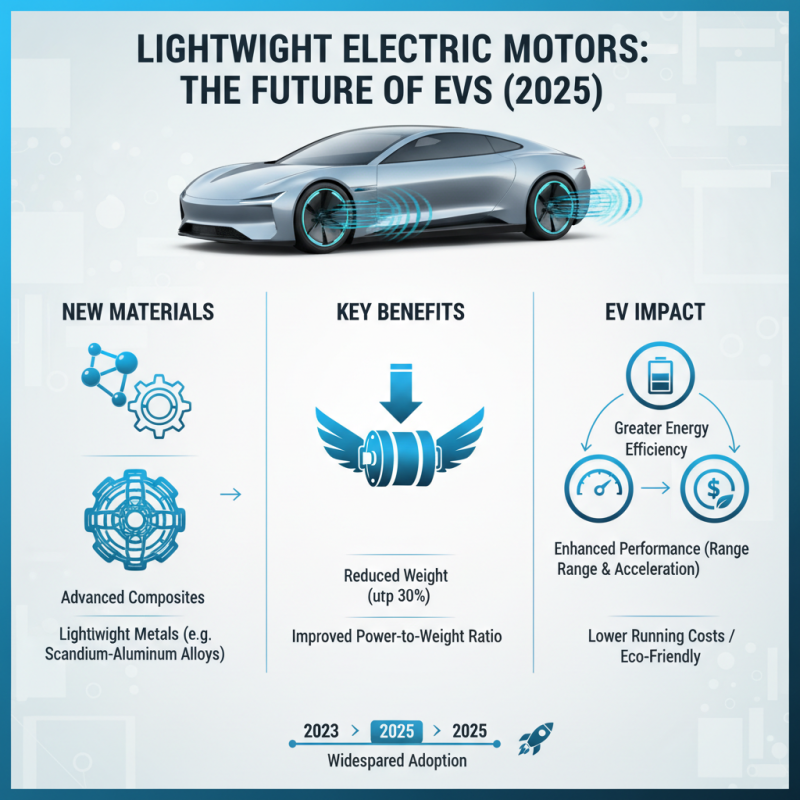

Advancements in material science are poised to transform the landscape of lightweight electric motors by 2025, bringing significant benefits to the efficiency and performance of electric vehicles. One of the most promising developments in this field is the use of advanced composites and lightweight metals, which can drastically reduce the weight of motor components without sacrificing strength or durability. This reduction in weight contributes directly to improved energy efficiency, as lighter motors require less power to operate while still delivering high performance.

Moreover, the exploration of novel materials, such as graphene and nano-structured alloys, is set to enhance thermal conductivity and manage heat more effectively in electric motor systems. Maintaining optimal temperatures is crucial for prolonging the life of electric motors and ensuring reliable operation. These high-performance materials also open the door to miniaturization, allowing for even smaller motors that could be integrated into a wider range of applications. As the industry continues to push for more sustainable and efficient technologies, the breakthroughs in material science will play a pivotal role in shaping the future of electric motor design and functionality.

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is set to revolutionize electric motor performance optimization by 2025. By harnessing real-time data gathered from connected devices, manufacturers can achieve unprecedented levels of efficiency and reliability in electric motor systems. AI algorithms will analyze performance metrics and usage patterns, allowing for the seamless fine-tuning of motor operations based on real-time demands. This proactive approach not only enhances performance but also significantly extends the lifespan of electric motors through predictive maintenance.

Moreover, the synergy between AI and IoT facilitates enhanced diagnostics and troubleshooting capabilities. With IoT sensors embedded in electric motors, data on operational status can be monitored continuously, identifying potential issues before they escalate into more serious problems. This level of insight translates to reduced downtime and improved overall system reliability. As industries increasingly adopt these smart technologies, the ability to optimize electric motors in real time will lead to more sustainable practices and substantial cost savings, marking a significant shift in how electric motors are managed in various applications.

| Trend/Innovation | Description | Potential Impact | Integration Level | Expected Adoption Rate (%) |

|---|---|---|---|---|

| AI-Driven Predictive Maintenance | Utilizing machine learning algorithms to predict motor failures before they occur. | Reduces downtime and maintenance costs. | High | 75 |

| IoT-Enhanced Efficiency Monitoring | Real-time performance data collection and analysis through connected sensors. | Improves energy efficiency and operational performance. | Moderate | 68 |

| Autonomous Motor Control Systems | Fully automated systems that adjust motor settings based on real-time conditions. | Enhances precision and adaptability in various applications. | High | 60 |

| Smart Grid Integration | Seamless integration of electric motors into smart grid systems for optimized energy usage. | Promotes sustainability and reduces energy waste. | Moderate | 62 |

| Advanced Materials for Motors | Utilization of lightweight and heat-resistant materials for higher performance. | Enhances durability and power-to-weight ratio. | High | 70 |

As the electric vehicle (EV) market continues to expand, the production of electric motors is increasingly pivoting towards sustainable manufacturing practices. These practices prioritize the reduction of environmental impact throughout the lifecycle of a motor. The adoption of eco-friendly materials is becoming a common trend, with manufacturers exploring alternatives to rare earth metals and focusing on recyclable and biodegradable components. Innovations in material science are paving the way for stronger, more efficient motors that maintain performance while minimizing ecological footprints.

Another key element of sustainable manufacturing in electric motor production is the implementation of energy-efficient processes. Factories are adopting renewable energy sources, such as solar and wind, to power their operations, significantly reducing greenhouse gas emissions. Additionally, advancements in automation and smart technologies are optimizing production lines, enhancing efficiency, and minimizing waste. Real-time monitoring systems are helping manufacturers track resource usage, while predictive maintenance ensures that machinery operates at its best, further contributing to sustainability goals. As these practices gain traction, the electric motor industry is well-positioned to lead in the global move towards a greener future.

The electric motor market, particularly focusing on ELC (Electric Linear Control) motors, is poised for significant transformation by 2025. Key players in this industry are investing heavily in innovative technologies to meet the rising demands for efficiency and sustainability. According to a recent report from an industry research firm, the global electric motor market is expected to reach approximately $147 billion by 2025, with a compounded annual growth rate (CAGR) of 7.1%. This growth is significantly driven by advancements in ELC motors, which are increasingly being adopted in automation and robotics, industries that are projected to require greater power efficiency and precision.

Major innovations in ELC motors include the integration of IoT capabilities that allow for real-time monitoring and predictive maintenance. By harnessing data analytics, companies can enhance the reliability and performance of their motors. Furthermore, the shift towards energy-efficient designs not only supports sustainability initiatives but also aligns with regulatory pressures for lower carbon footprints. A study indicated that energy-efficient motors could save manufacturers up to 30% on electric costs, making a strong financial argument for upgrading to newer technologies.

Tip: For businesses considering transitioning to ELC motors, focus on evaluating life cycle costs instead of just upfront prices. While the investment might seem higher initially, the long-term savings on energy and maintenance can be substantial. Additionally, maintaining an open dialogue with suppliers about upcoming innovations can help organizations stay ahead in a rapidly evolving market.