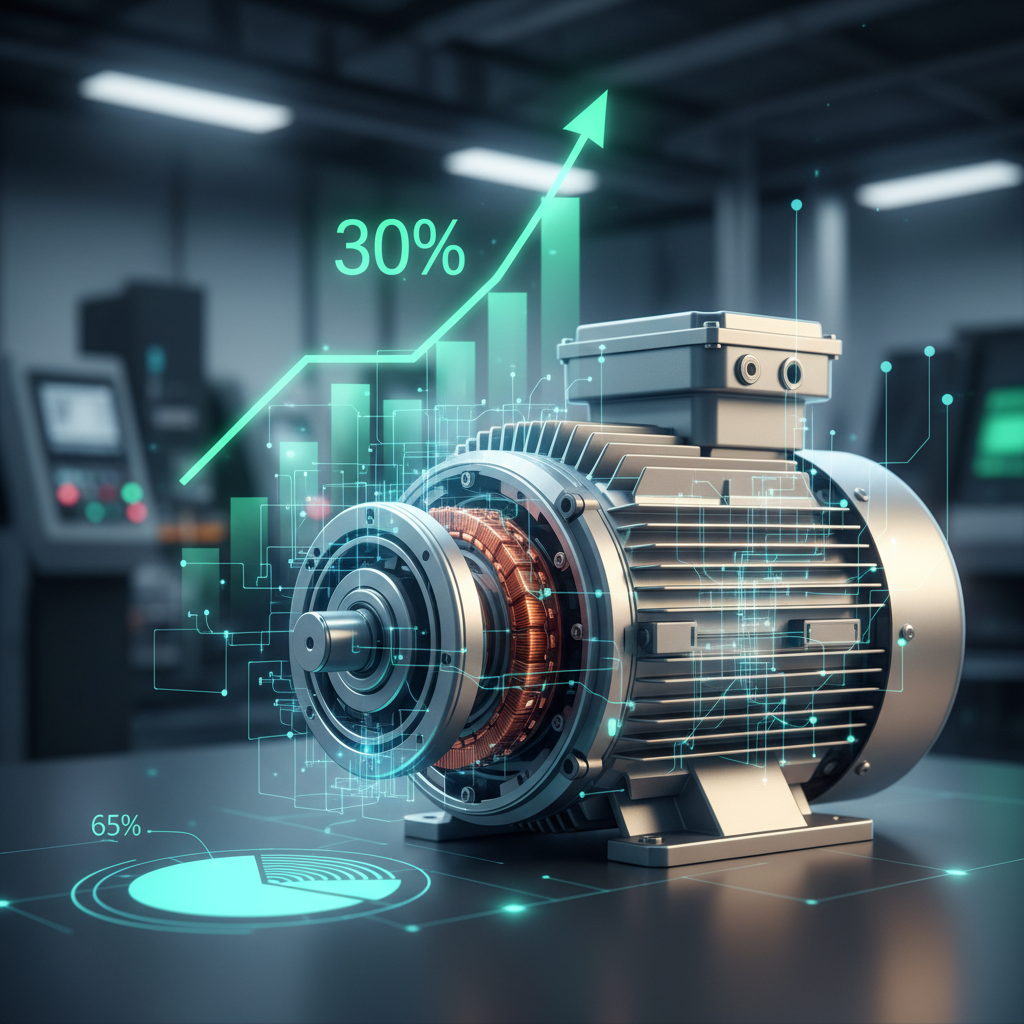

In today's fast-paced industrial landscape, selecting the correct AC motor is crucial for optimizing energy efficiency and operational performance. According to a report by the U.S. Department of Energy, electric motors account for nearly 65% of the industrial electricity consumption, emphasizing the importance of making informed choices when it comes to motor specifications. With the potential to enhance system efficiency by up to 30% when the right AC motor is utilized, businesses stand to benefit from significant cost savings and reduced environmental impact.

The proliferation of smart technologies and the Internet of Things (IoT) further complicates this selection process, as modern applications demand motors that not only perform efficiently but also integrate seamlessly with advanced control systems. A recent market analysis by MarketsandMarkets predicts that the global AC motor market will reach $25 billion by 2025, driven by ongoing technological advancements and the increasing focus on energy-efficient solutions. By understanding the key factors in choosing an AC motor, industries can leverage these best practices to improve performance and sustainability while aligning with regulatory standards and consumer expectations.

Choosing the right AC motor for your specific application is crucial for maximizing efficiency and performance. Different types of AC motors, such as induction and synchronous motors, offer unique advantages depending on the needs of your industrial automation process. For example, a report from the International Energy Agency indicates that selecting an efficient motor can reduce energy consumption by up to 30%, highlighting the importance of making an informed choice.

When assessing AC motors, it's essential to consider factors such as load requirements, speed control needs, and environmental conditions. For instance, if your application demands precise speed regulation, a variable frequency drive (VFD)-compatible motor might be the best option.

Tip 1: Assess your load characteristics to determine whether you need a single-phase or three-phase motor.

Tip 2: Look for energy-efficient models that comply with the latest efficiency standards to save on operational costs.

By aligning your motor selection with your specific application needs, you can not only enhance efficiency but also contribute to more sustainable industrial practices.

When selecting an AC motor, evaluating efficiency is crucial for optimizing energy consumption and enhancing overall performance. Energy savings can significantly impact operational costs, making it essential to analyze performance metrics such as the motor's efficiency rating and power factor. A high-efficiency motor often leads to reduced energy bills and lower carbon footprints, serving to improve both profit margins and environmental responsibility.

One essential tip is to consider the specific application where the motor will be used. Different tasks may require varying levels of torque and speed, affecting the motor's efficiency. Choosing a motor tailored to these requirements can enhance performance by up to 30%. Additionally, assessing the motor’s design can reveal potential energy savings; look for features that reduce energy loss, such as improved winding configurations or advanced cooling mechanisms.

Another critical factor is the installation environment. Motors operating in harsh conditions may suffer from inefficiencies due to wear and tear. Selecting motors with protective features can enhance durability and performance. Regular maintenance and monitoring of performance metrics are essential for sustaining efficient operation over the long term, ensuring that the motor continues to deliver optimal energy savings.

The chart above compares the efficiency percentages of various AC motors. Selecting a motor with higher efficiency can lead to significant energy savings and enhanced performance.

When selecting the right AC motor, understanding the load characteristics is paramount to maximizing efficiency and performance. Load characteristics refer to how the motor will be used, including the type of load (constant, variable, or starting), the duration of operation, and the presence of any fluctuating demands. Different applications place varying demands on a motor, and recognizing these nuances helps in choosing a motor that can handle specific requirements without unnecessary strain or energy loss.

For instance, a motor intended for heavy-duty applications may require a higher starting torque, while one used in variable speed applications should be compatible with speed control technologies. Assessing these load characteristics allows engineers to select motors that not only meet operational demands but also operate within optimal efficiency ranges. This tailored approach leads to enhanced energy efficiency, potentially unlocking significant savings as much as 30% in operational costs. Overall, a deeper understanding of load characteristics is crucial for making informed decisions in AC motor selection.

When considering the performance and efficiency of AC motors, control technologies play a pivotal role. Advanced control systems, such as Variable Frequency Drives (VFDs), can significantly improve motor efficiency. According to a report by the U.S. Department of Energy, using VFDs can enhance motor efficiency by up to 30%, particularly in applications with variable loads. These systems optimize power consumption by adjusting the motor speed according to actual demand, thus reducing energy waste and operational costs.

In choosing the right AC motor, it is essential to consider how these control technologies will impact performance. Utilizing smart controls can enable real-time monitoring and analytics, which in turn assists in predictive maintenance and can avert costly downtimes. A study from the International Journal of Electrical Power & Energy Systems indicated that integrating smart controls can lead to a reduction in energy use by 15-25%, directly improving overall motor efficiency.

To maximize AC motor efficiency, keep these tips in mind: always match the motor size to the application load, and consider the use of soft starters or VFDs to ensure smooth operation and energy savings. Additionally, ensure that the motor is properly maintained, as regular maintenance can further enhance performance and longevity, leading to sustainable energy consumption.

| Tip | Description | Efficiency Impact (%) |

|---|---|---|

| 1. Select Correct Power Rating | Choose a motor that closely matches the load requirements to prevent energy waste. | 10% |

| 2. Consider Motor Type | Choose between induction and synchronous motors based on application needs. | 5% |

| 3. Evaluate Motor Efficiency Rating | Look for high efficiency ratings (IE3 or IE4) to ensure optimal performance. | 8% |

| 4. Assess Load Characteristics | Understand the application load profile to choose the right motor specifications. | 6% |

| 5. Optimize Control Methods | Implement variable frequency drives (VFDs) for better speed control and efficiency. | 15% |

| 6. Ensure Proper Installation | Follow manufacturer guidelines for installation to avoid performance issues. | 4% |

| 7. Maintain Regular Servicing | Schedule periodic checks and maintenance to keep motors running efficiently. | 5% |

| 8. Analyze Temperature Ratings | Choose a motor with a suitable thermal rating for the operational environment. | 3% |

| 9. Look for Noise Levels | Select quieter motors for applications sensitive to noise pollution. | 2% |

| 10. Research Lifecycle Costs | Evaluate long-term costs, including energy use and maintenance during operation. | 8% |

When selecting the right AC motor, maintenance considerations play a crucial role in ensuring long-term reliability and optimal performance. Regular maintenance not only enhances the lifespan of the motor but also improves efficiency, thereby reducing operational costs. One essential tip is to implement a consistent maintenance schedule that includes routine inspections and servicing. This proactive approach helps identify potential issues before they escalate into major problems.

Another critical factor is lubrication. Proper lubrication minimizes friction, reducing wear and tear on the motor's components. Utilize the manufacturer's recommendations on lubrication types and intervals to maintain peak performance. Additionally, consider the environment in which the motor operates. Dust, moisture, and temperature fluctuations can impact reliability, so ensure that the motor is adequately housed and protected.

Lastly, don’t overlook the importance of monitoring motor performance through advanced diagnostic tools. These technologies can provide insights into operational efficiency and signal when maintenance is needed, helping to prevent unexpected downtime. By focusing on these maintenance aspects, you can ensure that your AC motor operates efficiently and reliably over the long term.