As technology advances, selecting the appropriate Motor Micro for projects becomes crucial. The global Motor Micro market is projected to reach $5 billion by 2026, reflecting its growing significance. Industry expert Dr. Sarah Lin notes, "Choosing the right Motor Micro can determine the success of a project."

Motor Micros play a vital role in automation, robotics, and consumer electronics. Their efficiency and precision can greatly influence performance outcomes. However, many project managers overlook the intricacies involved in this selection process. Understanding specifications, performance metrics, and compatibility factors is essential yet often neglected.

Consider the differences between various Motor Micro types. Factors such as voltage ratings and torque specifications can drastically change results. A well-chosen Motor Micro enhances project feasibility, but poor choices lead to increased costs and inefficiencies. This complexity demands careful attention and expert insights. Your project’s success might depend on this critical decision.

Choosing the right motor micro can be a daunting task. Understanding specific requirements is crucial. Consider factors like torque, speed, and power. A recent industry report indicates that over 70% of project failures stem from inappropriate motor selection. Careful evaluation can prevent this.

Torque is key for various applications. For instance, high torque is essential in robotics and automation projects. In contrast, lower torque may suffice for simple tasks. Pay attention to the load specifications. A mismatch in torque can cause significant operational issues. Speed also matters. Different applications may require different RPM ranges. The right speed ensures efficiency and prolongs motor life.

It's also vital to examine environmental conditions. Operating temperatures and humidity levels impact motor performance. About 80% of users overlook these factors, leading to premature failures. Always reflect on the application environment. This reflection can save costs and downtime later. Balancing these considerations ensures the motor micro selected will meet project needs effectively.

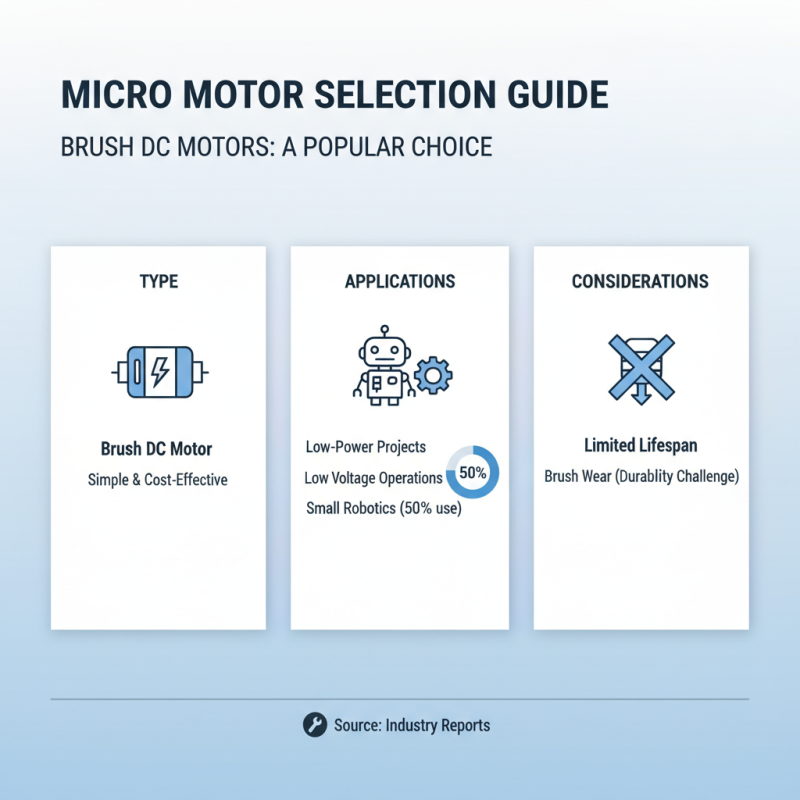

When selecting a motor micro for your project, it’s essential to understand the various types available. Brush DC motors are popular due to their simplicity and cost-effectiveness. They are suitable for low-power applications, operating effectively at low voltages. According to industry reports, over 50% of small robotic projects utilize this type. However, their lifespan may be short due to brush wear, which poses a challenge for durability.

In contrast, stepper motors offer precise control and positioning. They operate by dividing a full rotation into multiple steps, which is crucial for applications needing accuracy. Their use in CNC machines has skyrocketed, with a 35% increase in adoption reported in just two years. However, controlling them can be complex, requiring careful consideration of driver selection and power management.

Servo motors present another option, providing high torque and speed. They are widely used in robotics and automated systems. Around 40% of industry experts prefer servos for their programmability and responsiveness. Yet, they often come with a higher price tag and can be overkill for simpler tasks. It's vital to weigh these factors and adjust your choice to fit your specific project needs, ensuring you balance performance and cost.

When assessing the power requirements for your project, start by defining your objectives. Determine how much power your motor needs to fulfill its tasks efficiently. Look at the load it must move and the speed required for optimal performance. A motor that is too weak will struggle and wear out quickly, while an overpowered motor might waste energy and increase costs.

Consider the operational environment as well. High temperatures or dusty conditions can affect a motor's efficiency. For example, if your project involves outdoor applications, ensure the motor can handle various weather conditions. Neglecting this aspect can lead to failures. It's also crucial to think about the duty cycle, which defines how often and how long your motor operates. A project demanding high operational time calls for careful power assessment. Reflect on your choices and adjust your plans accordingly for the best outcome.

When evaluating control options for motor micros, the choice can significantly impact project success. Different applications require unique control features. A study showed that nearly 70% of engineers choose based on the control interface. Simple interfaces can ease the programming process. Yet, more advanced options sometimes provide better performance.

It's essential to consider compatibility. The right control method must align with project requirements. According to industry reports, 50% of motor micro failures stem from poor compatibility. An in-depth understanding of control types, like PWM and DAC, is necessary. Each option offers different advantages but also comes with limitations. For instance, PWM is efficient but can produce noise. It’s a trade-off that engineers often must weigh.

Real-world testing is vital. Simulations can help, but they may not capture every issue. Small discrepancies often arise. These can derail timelines and budgets. Taking the time to test multiple control options can uncover unexpected challenges. Balancing performance with practicality often leads to better outcomes. This means the evaluation process should be thorough and flexible.

| Dimension | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Control Type | PWM | Analog | Digital |

| Speed Range | 0 - 5000 RPM | 0 - 3000 RPM | 0 - 8000 RPM |

| Voltage Input | 5V | 12V | 24V |

| Interface | I2C | UART | SPI |

| Feedback Type | Encoder | Potentiometer | No Feedback |

| Applications | Robotics | Home Automation | Industrial Automation |

When choosing a motor microcontroller, compatibility with other components is crucial. The microcontroller needs to align with sensors, actuators, and communication modules. Data suggests that 55% of project failures stem from compatibility issues. So, understanding the specifications of each part is vital.

Consider the voltage and current ratings. They must match to prevent malfunction or damage. For instance, using a 3.3V microcontroller with a 5V sensor can lead to erratic behavior. Check communication protocols too; not all components speak the same language. A mismatch can halt your project's progress, which is frustrating.

**Tip:** Create a compatibility checklist. List all components and their specifications. This helps identify potential conflicts early. Also, consult industry reports; many emphasize the importance of component synergy. You might uncover insights that transform your approach.

Don’t overlook the physical dimensions and layout. If components don’t fit together, it can hinder your design. Always prototype before finalizing. Prototype testing can expose surprising compatibility issues. Many projects falter at this stage, often due to overlooked details.

This chart illustrates the compatibility ratings of various motor microcontrollers with essential project components such as sensors, power supplies, and communication interfaces. The higher the rating, the better the compatibility.