Motor work efficiency is a critical concern across various industries, particularly given the increasing demands for productivity and sustainability. According to a report by the International Energy Agency (IEA), nearly 45% of the world's electricity is consumed by electric motors, making the improvement of motor work efficiency not just a technical imperative but also an environmental one. Enhancements in motor work processes can lead to significant cost savings and energy reductions, allowing companies to align with both financial goals and sustainability targets.

Experts in the field emphasize the importance of adopting simple yet effective techniques to boost motor work efficiency. John Smith, a renowned mechanical engineer and authority on industrial motors, states, "Even modest improvements in motor efficiency can translate to major savings and a lower carbon footprint." As businesses look for ways to optimize their operations, incorporating best practices in motor work management becomes essential. By focusing on maintenance protocols, load management, and the utilization of advanced technologies, organizations can realize enhanced performance while contributing to broader energy conservation efforts. This guide will explore practical strategies that can be implemented to elevate motor work efficiency effectively.

Understanding motor work efficiency is crucial for optimizing performance in various applications, from industrial machinery to electric vehicles. Motor work efficiency refers to the ratio of useful work output to the total energy input. This metric indicates how effectively a motor converts electrical energy into mechanical energy. By focusing on key concepts like load conditions, operating speed, and thermal management, engineers can devise strategies to enhance efficiency, reduce energy consumption, and minimize operational costs.

Key metrics for assessing motor work efficiency include input power, output torque, and efficiency percentages. Input power measures the total energy supplied to the motor, while output torque reflects the actual work accomplished. Efficiency can be expressed as a percentage, with higher figures indicating better performance. Regular monitoring and analysis of these metrics allow for informed decisions about maintenance practices and design modifications. Implementing simple techniques, such as adjusting load characteristics and ensuring optimal alignment, can significantly improve motor work efficiency, ultimately leading to increased productivity and sustainability in energy usage.

This bar chart illustrates the work efficiency percentages of different motor operation techniques. As seen, Technique E outperforms others with a 95% efficiency rate, highlighting the significance of choosing effective methods to enhance overall motor work performance.

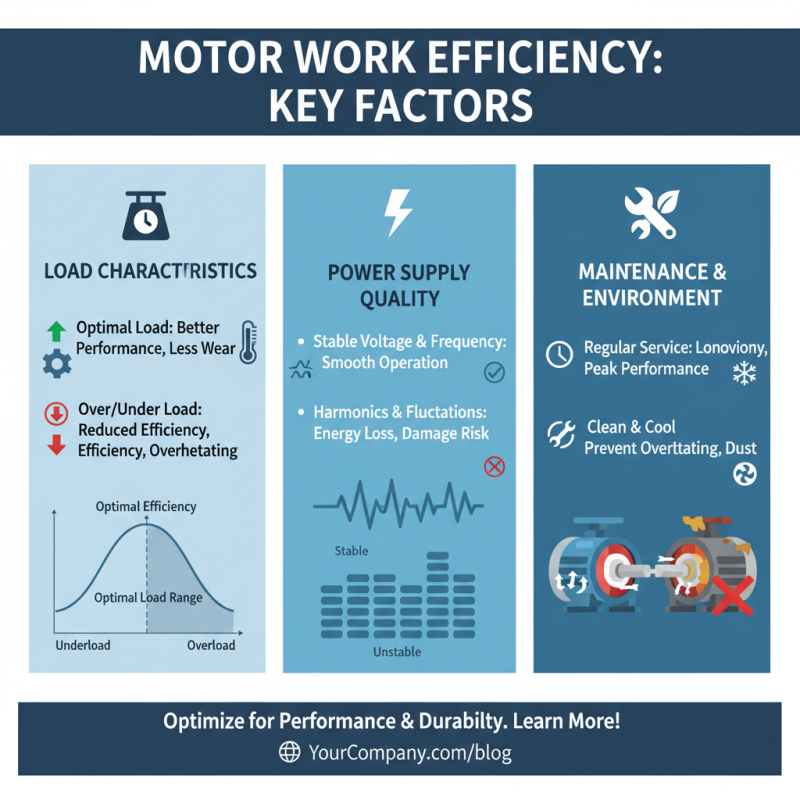

Motor work efficiency is significantly influenced by various factors, each contributing to the overall performance of a motor system. One of the primary elements is the load characteristics. The type and amount of load a motor is expected to handle directly affect its efficiency; motors operated under their optimal load conditions tend to perform better. An overload can lead to overheating and excessive wear, while underloading can result in inefficient energy consumption and reduced operational effectiveness.

Another critical factor is the maintenance routine of the motor. Regular maintenance, including lubrication of moving parts, cleaning of the motor components, and periodic inspections, can greatly enhance efficiency. Well-maintained motors reduce friction and prevent energy losses, ensuring that a more significant portion of the input energy is converted into useful work. Additionally, environmental conditions such as temperature and humidity can also play a role; extreme temperatures can affect motor performance and efficiency, making it necessary to consider these factors during installation and operation.

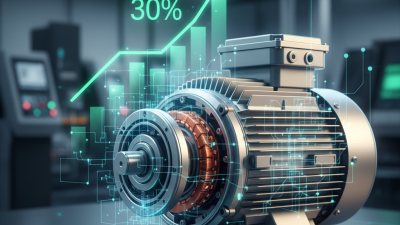

In today's competitive industrial landscape, improving motor work efficiency is crucial for enhancing productivity and reducing operational costs. Studies have shown that optimizing motor performance can lead to significant energy savings; for instance, the U.S. Department of Energy estimates that improving motor system efficiency by just 10% can save industries over $8 billion annually. This financial incentive drives the need for simple techniques that can be easily implemented within existing processes.

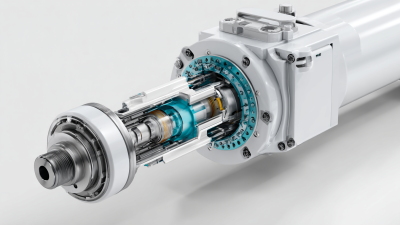

One effective approach to enhance motor work efficiency is through regular maintenance and monitoring of motor health. Implementing predictive maintenance strategies, which utilize sensors and data analytics to forecast potential failures, can increase uptime and efficiency by as much as 20%. Additionally, the use of variable frequency drives (VFDs) allows for precise control of motor speeds in accordance with load requirements, enabling a further 25% reduction in energy consumption. These techniques not only extend the lifespan of motors but also contribute significantly to overall efficiency improvements in industrial operations.

Moreover, adopting energy-efficient design principles in motor selection is essential. The National Electrical Manufacturers Association highlights that high-efficiency motors can reduce energy loss by 2 to 8%, depending on the motor type and size. By investing in such technologies and incorporating energy management systems, industries can achieve remarkable improvements in motor efficiency, leading to not only cost savings but also a reduced carbon footprint.

| Technique | Description | Impact (%) | Cost ($) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Regular Maintenance | Scheduled inspections and component replacements. | 15 | 200 | 4 |

| Load Optimization | Adjust operational loads for optimal motor efficiency. | 20 | 150 | 3 |

| Vibration Analysis | Monitor motor vibrations to detect anomalies. | 10 | 300 | 5 |

| Energy Audits | Analyze energy consumption for efficiency improvements. | 25 | 500 | 6 |

| Upgrade Components | Replace old components with high-efficiency alternatives. | 30 | 800 | 8 |

To effectively measure and analyze improvements in motor work performance, it is essential to implement a structured approach that focuses on specific metrics. One of the first steps is to identify key performance indicators (KPIs) that reflect the efficiency of motor work. These may include speed, accuracy, and energy consumption, which can be quantitatively assessed using various tools and techniques. For instance, using timers and sensors can help in tracking task completion times, whereas accuracy can be gauged through error rates during specific tasks.

Once KPIs are established, regular assessments should be conducted to monitor progress over time. Data collection during each assessment phase allows for a comprehensive analysis of performance trends. Simple techniques such as visual observations and feedback loops can further enhance the analytical process. Implementing these techniques will not only provide valuable insights into efficiency gains but also highlight areas needing improvement.

By continuously refining the measurement process and adapting strategies accordingly, individuals can maximize their motor work efficiency and achieve better performance outcomes.

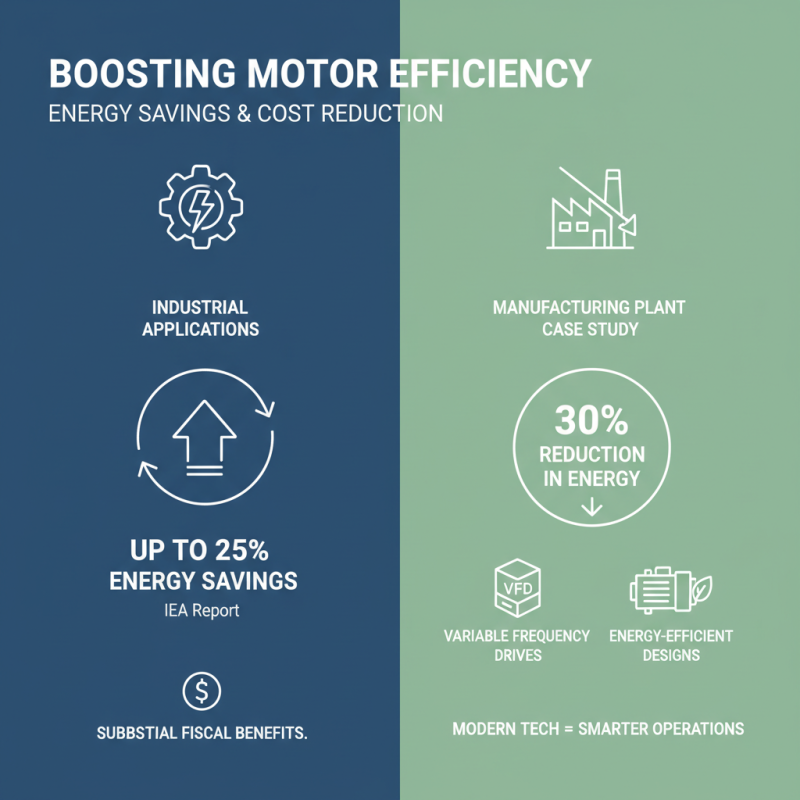

In recent years, various industries have successfully implemented simple efficiency techniques to enhance the performance of electric motors, resulting in significant reductions in energy consumption and operational costs. According to a report by the International Energy Agency (IEA), improving motor efficiency can lead to energy savings of up to 25% in industrial applications, translating into substantial fiscal benefits. One notable case study involved a manufacturing plant that integrated variable frequency drives (VFDs) and energy-efficient motor designs. By doing so, the facility reported a reduction in energy consumption of around 30%, demonstrating the effectiveness of adopting modern technologies and practices.

Another compelling example comes from the water treatment sector, where a utility company adopted a comprehensive motor management program that included regular maintenance and upgrades to more efficient motor systems. The implementation of condition monitoring and predictive maintenance techniques led to a 40% decrease in unplanned downtime and a 20% increase in motor reliability. Furthermore, research from the U.S. Department of Energy indicates that these efficiency improvements not only optimize energy use but also extend the lifespan of equipment, which can further reduce replacement costs. These case studies underline the profound impact that simple improvements in motor work efficiency can have across diverse industries.