In the realm of robotics, automation, and compact devices, the significance of the Mini Motor cannot be overstated. These small yet powerful components play a vital role in various applications, offering efficiency and versatility across a wide range of projects. From hobbyist inventions to larger industrial machines, choosing the right Mini Motor tailored to your specific needs can greatly enhance performance and usability.

As we delve into the different types of Mini Motors available and the factors to consider when making your selection, it is crucial to understand how the specifications and features impact their functionality. Whether you require precision, speed, or torque, this guide will equip you with the knowledge needed to select the ideal Mini Motor for your application, ensuring that your project runs smoothly and effectively. In understanding the intricacies of these motors, you will be better prepared to harness their capabilities in a way that aligns with your objectives.

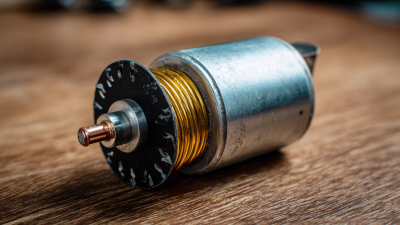

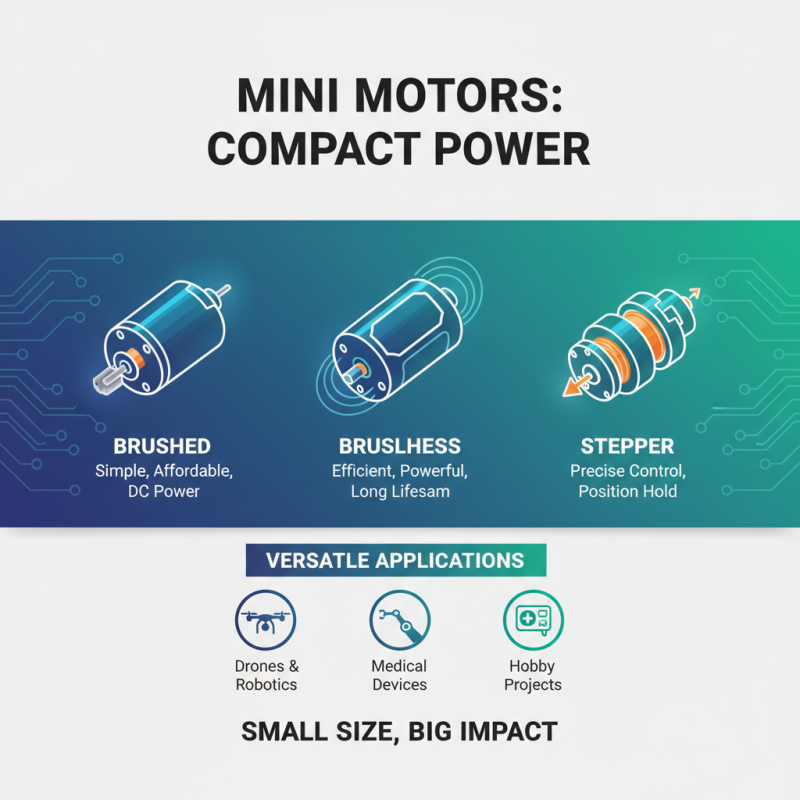

Mini motors are compact, versatile devices that play a critical role in various applications, from hobby projects to professional machinery. Typically characterized by their small size and lightweight nature, mini motors are designed to deliver sufficient power while being energy-efficient. These motors can be classified into different types, such as brushed, brushless, and stepper motors. Each type serves unique purposes depending on the desired application, making it essential to understand their differences before making a choice.

When choosing a mini motor, consider the specific requirements of your project. Pay attention to factors like voltage, torque, speed, and size to ensure optimal performance. For instance, if your application demands precise control, a stepper motor might be the best choice, while a brushed motor could be ideal for simpler tasks.

Tips:

1. Evaluate the weight and dimensions of your project to select a motor that fits well within your design.

2. Always assess the power requirements and ensure your power supply can meet the motor's needs without risking damage.

3. Research and compare different motor types to find the one that aligns best with your project's specific functions and constraints.

Mini motors play a crucial role in various industries due to their versatility and efficiency. They are commonly found in applications ranging from consumer electronics to industrial automation. According to a report by Research and Markets, the global mini motor market is expected to reach USD 4.5 billion by 2026, growing at a CAGR of 5.2%. This growth is driven by the increasing demand for smaller, more efficient motors in sectors such as automotive, medical devices, and robotics.

In the automotive industry, mini motors are widely used in applications like window regulators, seat adjusters, and electric throttle control, supporting the trend towards electric and automated vehicles. In medical devices, mini motors can be found in surgical instruments, pumps, and imaging systems, where precision and reliability are paramount. Additionally, their small footprint and lightweight design enable integration into compact devices, making them ideal for modern consumer electronics like drones and smartphones.

Tips: When selecting a mini motor for your project, consider factors like torque, speed, and power requirements specific to your application. Understanding the environment in which the motor will operate—such as temperature ranges and exposure to moisture—can also influence your choice. Additionally, it’s beneficial to consult industry specifications and select a motor that meets or exceeds these standards to ensure optimal performance and longevity in your application.

| Application | Industry | Motor Type | Voltage (V) | Power (W) |

|---|---|---|---|---|

| Robotics | Manufacturing | DC Motor | 6 | 3 |

| Electric toothbrush | Consumer Electronics | Brushless Motor | 3.7 | 1.5 |

| Drones | Aerospace | Brushless Motor | 11.1 | 100 |

| Power tools | Construction | Brushed Motor | 18 | 600 |

| Gate openers | Automotive | Gear Motor | 12 | 50 |

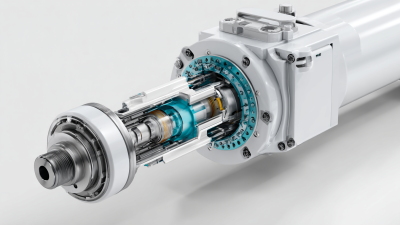

When choosing a mini motor, several key specifications should be carefully considered to ensure it meets your specific needs. One of the most critical factors is the motor's voltage and current ratings. These specifications determine the power output and efficiency of the motor. It's essential to match the mini motor's voltage with your power supply to prevent any damage or underperformance. Additionally, check the current rating to ensure that it can handle your application's demands without overheating.

Another important consideration is the motor's speed and torque characteristics. Depending on your intended use, you may require a motor that operates at high RPMs for quick movements or one that provides high torque for heavier loads. Understanding the balance between speed and torque will help you select a mini motor that performs optimally for your specific application.

Tips: Always consult the manufacturer's datasheet for detailed specifications and performance curves. This will provide insight into how the motor performs under different loads and conditions. Moreover, consider the physical dimensions and weight of the motor, especially if space is a constraint in your project. A compact design can often make integration much easier while still delivering the performance you need.

When choosing a mini motor for various applications, understanding the differences between brushed and brushless motor types is crucial. Brushed motors have been widely used for decades in numerous devices due to their simplicity and cost-effectiveness. They operate through mechanical brushes that create electrical contact with the motor’s commutator, generating torque. According to recent industry reports, brushed motors tend to have a lower initial cost, making them attractive for hobbyists and low-budget projects. However, they also have higher maintenance requirements due to brush wear and typically lower efficiency, which can reduce their lifespan after extended use.

On the other hand, brushless motors have gained significant traction in recent years, particularly in applications where performance and energy efficiency are paramount. Research indicates that brushless motors can be up to 80% more efficient than their brushed counterparts, offering improved torque and speed control. Their design eliminates the need for brushes, resulting in less friction, reduced heat generation, and a longer operational lifespan. Industry estimates suggest that brushless motor sales are projected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years, reflecting their increasing adoption in the automotive, aerospace, and robotics sectors.

Given these distinctions, the choice ultimately depends on the specific requirements of the project at hand. For short-term, cost-sensitive applications, brushed motors may be suitable. Conversely, for long-term usage and high-performance demands, investing in a brushless motor is often the more prudent option.

When selecting a mini motor, understanding industry standards and performance metrics is crucial to ensuring that it meets your specific requirements. Performance metrics typically include parameters such as torque, speed, efficiency, and thermal management. Torque indicates the motor's ability to handle loads, while speed is essential for applications that require rapid movement or precision. Additionally, efficiency measures how effectively the motor converts electrical energy into mechanical power, which can significantly impact operating costs, especially in long-term applications.

Another critical industry standard to consider is the motor's form factor, which should align with the space and application requirements. Mini motors come in various sizes and configurations, and selecting one with the appropriate dimensions and mounting options will facilitate integration into your project.

Thermal management is also an essential metric; it has a direct effect on the motor's longevity and reliability. A motor that operates within its optimal temperature range will perform better and last longer, reducing the need for maintenance or replacement. Understanding and evaluating these performance metrics against your operational needs is key to choosing the best mini motor for your application.