In the realm of modern engineering and technology, the PMDC motor has emerged as a pivotal component in various applications. Short for Permanent Magnet Direct Current motor, this type of motor is celebrated for its simplicity, efficiency, and effectiveness in delivering consistent performance across a range of settings. The unique characteristics of PMDC motors allow them to excel in applications that require variable speed control and precise positioning, making them indispensable tools in industries from automotive to robotics.

As we delve into the top 10 PMDC motor applications you need to know about, we will explore the diverse ways these motors enhance functionality and innovation in projects. Whether it’s their role in driving electric vehicles, powering home appliances, or enabling automated machinery, PMDC motors play a critical role in ensuring that devices operate smoothly and reliably. Understanding these applications not only broadens your knowledge of PMDC motors but also equips you with insights to make informed decisions for your engineering projects.

Permanent Magnet Direct Current (PMDC) motors are a critical component in many modern applications due to their efficiency and simplicity. Utilizing permanent magnets for their field instead of windings, these motors provide a compact and cost-effective solution for various projects. They excel in environments where high torque and reliability are essential, making them ideal for a wide range of uses, from automotive systems to domestic appliances and industrial machinery.

When considering a PMDC motor for your project, it’s important to assess the specific requirements, including voltage, speed, and torque. These motors are particularly preferred in applications where controlled braking and quick response times are vital. Tips for maximizing the performance of PMDC motors include ensuring proper heat dissipation and using appropriate gear ratios to enhance torque and efficiency.

Another key advantage of PMDC motors is their straightforward design, which results in lower maintenance needs and increased operational reliability. As technology evolves, their role continues to expand, reinforcing their importance in sectors such as robotics, medical equipment, and renewable energy solutions. By understanding the operational principles and benefits of PMDC motors, engineers and designers can better implement them in innovative projects.

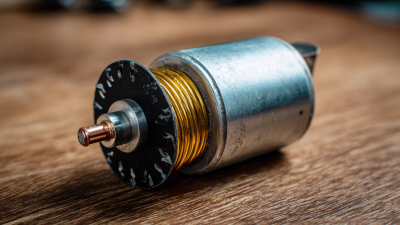

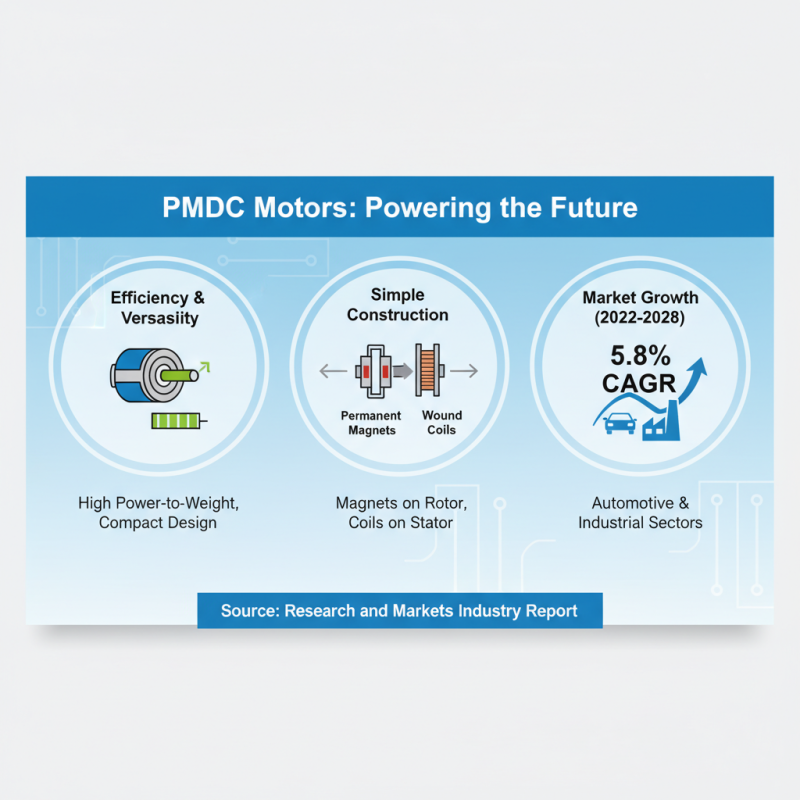

Permanent Magnet Direct Current (PMDC) motors are widely recognized for their efficiency and versatility in various applications. One common feature of PMDC motors is their simple construction, which typically comprises a rotor containing permanent magnets and a stator with wound coils. This design allows for a higher power-to-weight ratio compared to other motor types, making PMDC motors an ideal choice for compact applications that require high torque output. According to a recent industry report by Research and Markets, the PMDC motor market is projected to grow at a CAGR of 5.8% from 2022 to 2028, driven by increasing demand in automotive and industrial sectors.

Another characteristic that sets PMDC motors apart is their inherent speed control capabilities. By adjusting the supply voltage or employing Pulse Width Modulation (PWM) techniques, users can achieve precise speed control, which is beneficial in applications like robotics and conveyor systems. Furthermore, PMDC motors exhibit low mechanical wear due to fewer moving parts, enhancing their reliability and longevity. Industry analysts indicate that the trend toward automation and electrification in manufacturing processes will further bolster the adoption of PMDC motors, reinforcing their significance in current and future engineering projects.

Permanent Magnet Direct Current (PMDC) motors have become a pivotal component in several industries due to their efficiency and performance capabilities. Key industries utilizing PMDC motors include automotive, robotics, aerospace, and consumer electronics. According to a recent report by Research and Markets, the global PMDC motor market is projected to grow at a CAGR of 6.4% from 2023 to 2030. This growth is fueled by the continuous demand for high-efficiency drives that can adapt to a variety of applications.

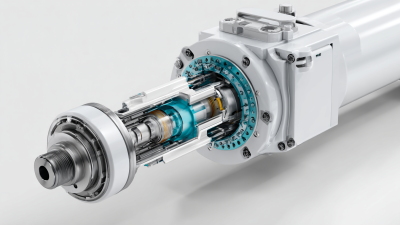

In the automotive sector, PMDC motors are increasingly used in electric vehicles (EVs), where they provide smooth and reliable power delivery. The efficiencies offered by PMDC motors can range up to 90%, enabling manufacturers to produce vehicles with extended battery life. Additionally, in robotics, these motors are favored for their compact size and high torque-to-weight ratio, facilitating better performance in robotic arms and autonomous vehicles. Industries are prioritizing PMDC motors to streamline operations and reduce energy costs.

Tips: When selecting a PMDC motor for your project, consider the application requirements such as torque, speed, and size constraints. Also, examine the motor’s thermal characteristics to ensure optimal performance under varying load conditions. Furthermore, integrating advanced control systems can significantly enhance the operational efficiency of PMDC motors, contributing to increased productivity in industrial applications.

Permanent Magnet Direct Current (PMDC) motors are widely utilized in various industries due to their efficient design and ease of control. One prominent application is in electric vehicles, where PMDC motors provide the necessary torque and efficiency to enhance driving performance. Their compact size and lightweight construction make them ideal for automotive applications, allowing for more efficient energy consumption and better battery life.

Another significant application of PMDC motors is in robotics. These motors are often employed in robotic arms and automated systems, where precision and responsiveness are critical. The ability to control speed and torque with high accuracy makes PMDC motors particularly suited for tasks that require fine movements, such as in assembly lines or surgical robots. Moreover, their low maintenance needs contribute to the overall reliability and cost-effectiveness of robotic systems.

Additionally, PMDC motors play a crucial role in home appliances, like vacuum cleaners and washing machines. Their ability to provide variable speed control without complex systems allows manufacturers to design more user-friendly and efficient appliances. The consistent performance and durability of PMDC motors ensure that they meet the demands of daily household tasks, making them essential components in modern home technology.

This bar chart illustrates the various applications of PMDC motors in different projects. The applications are ranked based on their common usage in the industry.

As industries continue to evolve, the demand for innovative technologies in PMDC (Permanent Magnet Direct Current) motor applications is surging. According to a recent report by Research and Markets, the global market for PMDC motors is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This trend highlights the increasing reliance on PMDC motors in sectors such as automotive, robotics, and industrial automation, where efficiency and performance are paramount.

One of the most notable future trends in PMDC motor technology is the integration of advanced electronic controls, enabling more precise speed and torque management. Recent advancements in sensor technology, such as Hall Effect sensors, are also enhancing motor control, resulting in improved energy efficiency and reduced wear. Furthermore, the push towards sustainable energy solutions is driving innovations in PMDC motors, with many manufacturers focusing on lightweight materials and optimized designs to reduce their carbon footprint. These innovations not only streamline production but also cater to the increasing consumer demand for eco-friendly products, making PMDC motors a crucial component in the sustainable technology landscape.