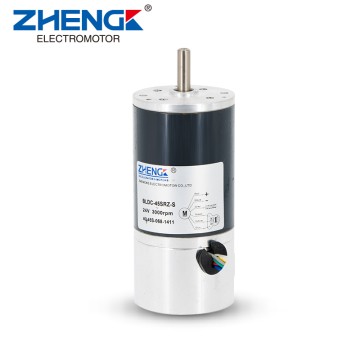

Zhengke DC Motors for Automotive – Trusted Manufacturer & Reliable Supplier

As a leading manufacturer of DC motors for automotive applications, Zhejiang Zhengke Electromotor Co., Ltd. is dedicated to providing reliable and high-quality components essential for your projects. Our advanced factory technology enables us to produce motors that comply with rigorous industry standards. We are committed to excellence and customer satisfaction, offering tailored solutions to meet your specific requirements and ensure optimal performance. With our industry experience, we can assist you in selecting the right products for your needs. Let's work together to foster innovation in the automotive sector. Your success is our top priority, and we are here to support you at every step. Contact us to learn how our premium DC motors can meet your demands.Methods To choose Dc Motor Automotive Manufacturer Factory Custom Solutions,

When selecting a DC motor automotive manufacturer, it’s crucial to consider several key factors to ensure that you receive custom solutions that meet your specific needs. First and foremost, evaluating the manufacturer’s experience in producing Gear DC Motors is essential. A company with a track record of excellence and diverse applications can offer invaluable insights and proven solutions tailored to various automotive requirements. Look for manufacturers that demonstrate a strong research and development team. Our company prides itself on a robust R&D department equipped with advanced technology and innovative thinking. This not only facilitates the creation of high-quality products but also ensures that we remain adaptive to evolving industry trends and customer demands. Skilled engineers and a dedicated workforce further guarantee that each product is crafted with precision, enhancing reliability in your automotive applications. Lastly, consider the manufacturer’s ability to provide professional technology support throughout the collaboration process. It’s important to partner with a factory that is committed to understanding your unique project needs and offering ongoing technical assistance. By choosing a manufacturer like ours, which emphasizes quality, collaboration, and innovation, you can secure the perfect DC motor solutions that drive your automotive success.

Methods To Choose Dc Motor Automotive Manufacturer Factory Custom Solutions

| Parameter | Importance Level | Considerations |

|---|---|---|

| Production Capacity | High | Ensure the manufacturer can meet your volume requirements. |

| Quality Standards | Critical | Look for certifications such as ISO and adherence to industry standards. |

| Customization Capabilities | High | Assess the ability to create tailored solutions based on specific requirements. |

| Technical Support | Important | Evaluate the level of pre-sales and post-sales support offered. |

| Cost-effectiveness | Moderate | Analyze pricing in relation to the quality and features offered. |

| Lead Time | High | Understand the average time frame from order to delivery. |

| Reputation and Experience | Critical | Research manufacturer history and customer reviews. |

| Technological Advancements | Important | Ensure they utilize up-to-date technology in their manufacturing processes. |

Methods To choose Dc Motor Automotive Manufacturer Application Sets the Industry Standard

G

Grace Baker

Stellar product! The representatives showcased immense professionalism and support.

31 May 2025

S

Samantha Hill

What an amazing product! The professionalism of the staff made all the difference.

03 July 2025

T

Tyler Bennett

Amazing quality! The customer representatives were professional and really attentive.

01 June 2025

A

Andrew Hayes

Above my expectations! The support team was attentive and knowledgeable.

31 May 2025

S

Sophie Green

Excellent product! The staff were knowledgeable and really cared about my experience.

15 May 2025

C

Caroline West

Wonderful product! The support team went above and beyond to assist me.

26 June 2025