Top DC Motor Manufacturing Processes Used by Leading Factories for High Quality

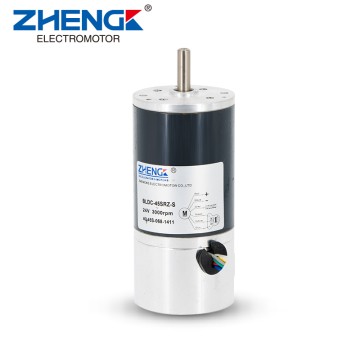

In the dynamic world of Electric Motors, mastering the DC Motor Manufacturing Process is essential for production efficiency. Our advanced factories utilize innovative techniques to deliver high-quality, dependable products tailored to your requirements. As a wholesale supplier, we offer an extensive selection of DC motors so that each stage of our manufacturing is geared toward enhancing performance and longevity for a variety of applications. We focus on meticulous craftsmanship and a commitment to excellence, ensuring you receive top-tier products. Whether sourcing components for assembly lines or fulfilling large orders for resale, we provide solutions to meet your needs. Partnering with us grants you access to superior electro motors supported by a reliable supply chain. Enhance your business offerings with our premium DC motor solutions designed for durability and efficiency.

Must-Know Tips For Dc Motor Manufacturing Process Factories Dominates Global Reach

In the fast-paced world of technology, understanding the manufacturing processes of DC motors is crucial for global procurement professionals looking to optimize their supply chains. As a leading manufacturer with extensive experience in producing high-quality Gear DC Motors, we ensure our customers receive not just superior products, but also exceptional technological support. Our dedicated R&D team constantly innovates, leveraging advanced equipment and skilled engineers to perfect every aspect of our manufacturing process. The key to our global dominance lies in our commitment to quality and efficiency. By integrating cutting-edge technology with skilled craftsmanship, we streamline production while maintaining rigorous quality control standards. This not only helps us meet the diverse needs of international clients but also positions us as a reliable partner in the competitive market. For businesses seeking reliable DC motor solutions, understanding our well-established manufacturing processes can provide insights into how we deliver outstanding value with every product. As you explore potential suppliers for your DC motor needs, consider the impact of partnering with a factory that prioritizes innovation, quality, and professional technology. Our holistic approach ensures that every DC motor not only meets but exceeds industry standards, empowering your business to thrive in a global marketplace. Let us help you elevate your operations with our premium gear DC motors, backed by a foundation of expertise and a commitment to excellence.

Must-Know Tips For DC Motor Manufacturing Process Factories Dominates Global Reach

| Dimension | Description | Value |

|---|---|---|

| Motor Type | Types of DC motors | Brush, Brushless |

| Manufacturing Materials | Common materials used | Copper, Steel, Nylon |

| Quality Standards | Global quality certifications | ISO 9001, RoHS |

| Production Capacity | Units produced per month | 10,000-50,000 |

| Lead Time | Average shipment time | 4-6 weeks |

| Testing Procedures | Methods for quality assurance | Electrical testing, Thermal testing |

| Market Reach | Regions served | North America, Europe, Asia |

| Cost Efficiency | Cost per unit | $5 - $15 |

Premier Dc Motor Manufacturing Process Factories Manufacturers You Can Rely On More Than a Supplier - A Partner

C

Charlotte Allen

I love this item! The quick service response and knowledgeable staff were commendable.

28 May 2025

L

Lily Martinez

I appreciate the quality and the thoroughness of the customer service team.

30 June 2025

A

Andrew Hayes

Above my expectations! The support team was attentive and knowledgeable.

31 May 2025

S

Sophie Green

Excellent product! The staff were knowledgeable and really cared about my experience.

15 May 2025

A

Autumn Davidson

Great item! The support staff were engaging and helpful throughout the process.

03 June 2025

O

Owen Nelson

High-quality item! The after-sales service was very rapid and insightful.

15 June 2025