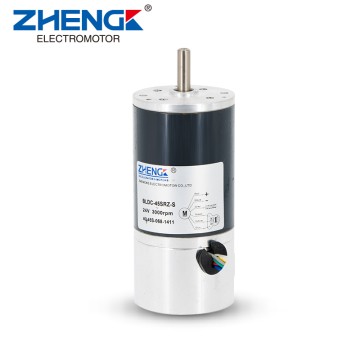

Zhengke DC Motors: Top Quality Suppliers & Manufacturers for Every Requirement

As a leading provider of high-quality DC Motor Products, we are dedicated to offering dependable solutions tailored to various industrial applications. Our motors are engineered for exceptional efficiency, durability, and performance, ensuring outstanding reliability across a broad range of uses. Each product undergoes rigorous quality assessments to guarantee optimal functionality. We prioritize customer satisfaction and personalized service, guiding you in selecting the perfect DC motor to meet your specific needs. With extensive industry experience and a commitment to excellence, we strive to forge long-lasting partnerships with our clients. Count on us to support your projects with reliable, top-tier products.10 Essential Tips For Dc Motor Product Ahead of the Curve Factory

In today’s fast-paced manufacturing landscape, staying ahead in the DC motor industry is crucial for businesses looking to secure a competitive edge. Here are ten essential tips to ensure your DC motor products meet the evolving demands of global buyers. First and foremost, leverage the expertise of a strong R&D team to innovate continuously. Understanding the latest trends and technologies allows for the creation of motors that not only meet but exceed customer expectations in efficiency and performance. Investing in advanced equipment is equally important. State-of-the-art machinery enhances precision and quality during the manufacturing process, ensuring that each product meets international standards. This commitment to quality is supported by skilled engineers and a dedicated workforce. Collaborating closely with these professionals ensures that any challenges faced during production are swiftly addressed, further refining the quality of the final product. Lastly, fostering professional relationships with your customers is key. Providing technical support and customized solutions can significantly enhance customer satisfaction and loyalty. By following these tips, manufacturers can position their DC motor products ahead of the curve, attracting a global clientele and establishing a robust presence in the market.

10 Essential Tips For DC Motor Product Ahead of the Curve Factory

| Tip | Description | Benefits |

|---|---|---|

| 1. Choose the Right Motor Size | Select an appropriate size based on the application requirements. | Ensures efficiency and longevity of the motor. |

| 2. Optimize Voltage Levels | Use the correct voltage to avoid overheating and inefficiency. | Improves performance and reduces energy costs. |

| 3. Implement Proper Cooling Systems | Incorporate fans or heat sinks to manage temperature. | Enhances operational reliability and lifespan. |

| 4. Utilize Feedback Control Systems | Integrate sensors to monitor and adjust performance. | Provides increased precision and accuracy in operation. |

| 5. Regular Maintenance Checks | Schedule periodic inspections and maintenance. | Prevents breakdowns and extends motor life. |

| 6. Ensure Proper Alignment | Align motors with their loads to minimize wear. | Reduces vibration and increases efficiency. |

| 7. Use Quality Components | Source reliable and high-performance parts for assembly. | Ensures durability and peak performance. |

| 8. Implement Safety Protocols | Establish safety measures and emergency procedures related to operations. | Protects personnel and equipment from hazards. |

| 9. Test for Environmental Conditions | Evaluate motor performance under varying conditions. | Ensures reliability in diverse environments. |

| 10. Invest in Training | Provide training for staff on operating and maintaining DC motors. | Improves efficiency and reduces operational errors. |

How To Identify Dc Motor Product Your End-to-End Solution Application

L

Logan Smith

I can’t recommend this enough. The quality is impeccable, and the service team is always ready to help.

25 June 2025

E

Ethan Hall

Beyond my expectations in terms of quality. The team knows their stuff and helps promptly.

01 July 2025

L

Lily Martinez

I appreciate the quality and the thoroughness of the customer service team.

30 June 2025

M

Michael Wright

Very pleased with my purchase. The after-sales service delivered exceptional professionalism all the way.

25 May 2025

A

Anabelle Clark

What a fantastic product! The service team displayed expertise that put my mind at ease.

15 June 2025

E

Elias Martinez

High-quality standard! The after-sales support was fantastic and very helpful.

11 June 2025