Premium Robot Gear Motors from Leading Manufacturers - High Quality Wholesale Options

When sourcing high-quality Robot Gear Motors, choosing a reputable manufacturer is essential. I highly recommend Zhejiang Zhengke Electromotor Co., Ltd., known for their exceptional products tailored to meet diverse industrial needs. Their gear motors are designed with a strong focus on quality and performance, ensuring reliable operation for your robotics projects. What differentiates them is their use of advanced technology and materials, resulting in superior durability and reliability. They also offer a range of custom options to suit specific requirements, making them a versatile partner for any business. Opting for Zhejiang Zhengke means investing in a reliable partnership with a manufacturer committed to customer satisfaction. You won't be disappointed with their high-quality offerings!

Expert Choice of High-Quality Robot Gear Motor Manufacturers Sets the Industry Standard Dominates

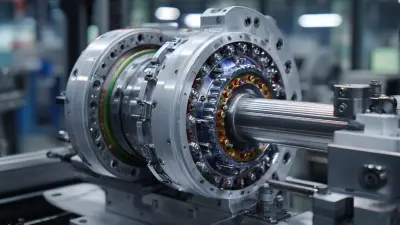

In the ever-evolving landscape of robotics, the choice of gear motors is critical in determining the performance and efficiency of the entire system. As global demand for high-quality robotics components continues to rise, our company stands out as a leading manufacturer of gear Dc Motors. With rich experience in the industry, we have established a reputation for excellence, setting standards that are emulated across the market. Our specialized gear motors are engineered to meet the rigorous demands of various applications, ensuring reliability and longevity. What sets us apart is not only our advanced manufacturing capabilities but also our commitment to innovation. Our robust R&D team continuously explores new technologies and designs to enhance motor performance and efficiency. Coupled with our state-of-the-art equipment and a skilled workforce, we are able to deliver products that exceed customer expectations. Clients can trust that they are not just purchasing motors, but also gaining access to professional technical support that can guide them in selecting the right solutions for their needs. As the industry standard for gear motor manufacturers, we understand that every detail matters in robotics applications. We are dedicated to providing the highest quality products that drive success for our customers globally. By partnering with us, procurement professionals can ensure that they are sourcing from a reliable distributor committed to fostering innovation and delivering exceptional value. Together, we can shape the future of robotics, one gear motor at a time.

Expert Choice of High-Quality Robot Gear Motor Manufacturers Sets the Industry Standard Dominates

| Manufacturer Type | Geared Motor Efficiency (%) | Max Torque (Nm) | Operating Voltage (V) | Lead Time (Weeks) | Warranty (Years) | Customer Satisfaction Rating (out of 5) |

|---|---|---|---|---|---|---|

| Type A | 85 | 10 | 24 | 5 | 2 | 4.5 |

| Type B | 90 | 7 | 12 | 3 | 1 | 4.0 |

| Type C | 78 | 9 | 36 | 4 | 3 | 4.8 |

| Type D | 95 | 15 | 48 | 6 | 5 | 4.7 |

Key Steps to Choosing High-Quality Robot Gear Motor Manufacturers Your Trusted OEM Partner Market Leader

Z

Zoe Thompson

Impressive overall! The quality of the product and professionalism of the service were noteworthy.

03 July 2025

A

Amelia Hall

What a memorable experience! The quality and service were impeccable.

17 June 2025

M

Maya Bennett

Fantastic product and incredible support. A wonderful purchasing experience!

08 June 2025

V

Victoria Price

High-quality product! The professional support team made everything effortless.

18 June 2025

C

Carter Lewis

Superb craftsmanship! The support team was efficient and very knowledgeable.

12 June 2025

C

Cassidy Kim

Great quality! Their follow-up support was especially impressive and punctual.

14 May 2025