Advantages and disadvantages of planetary gear motors

Advantages:

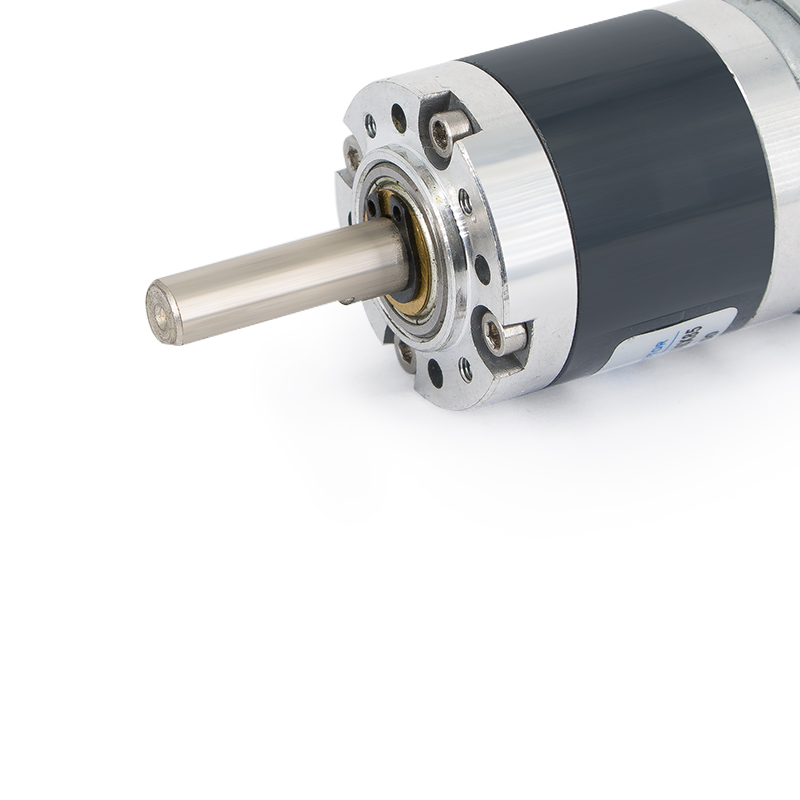

1. Compact design and high transmission efficiency

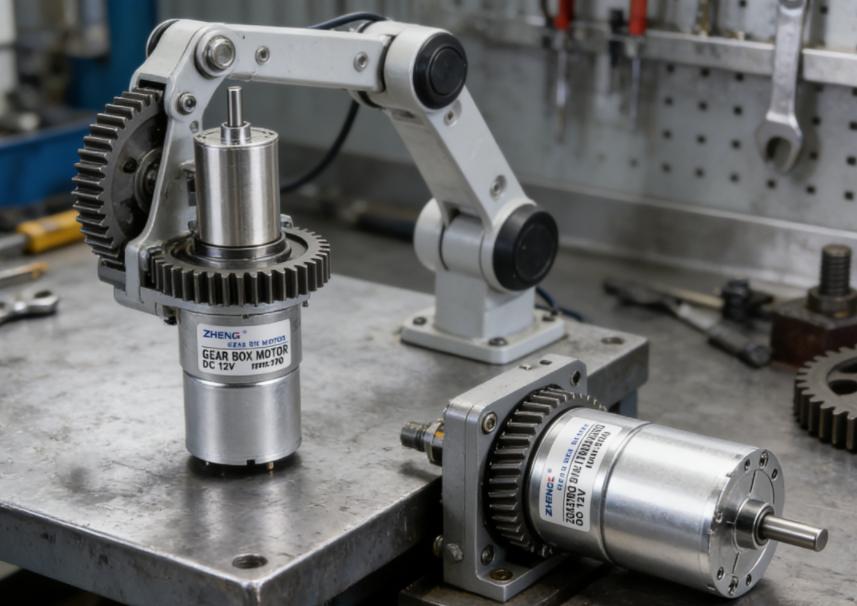

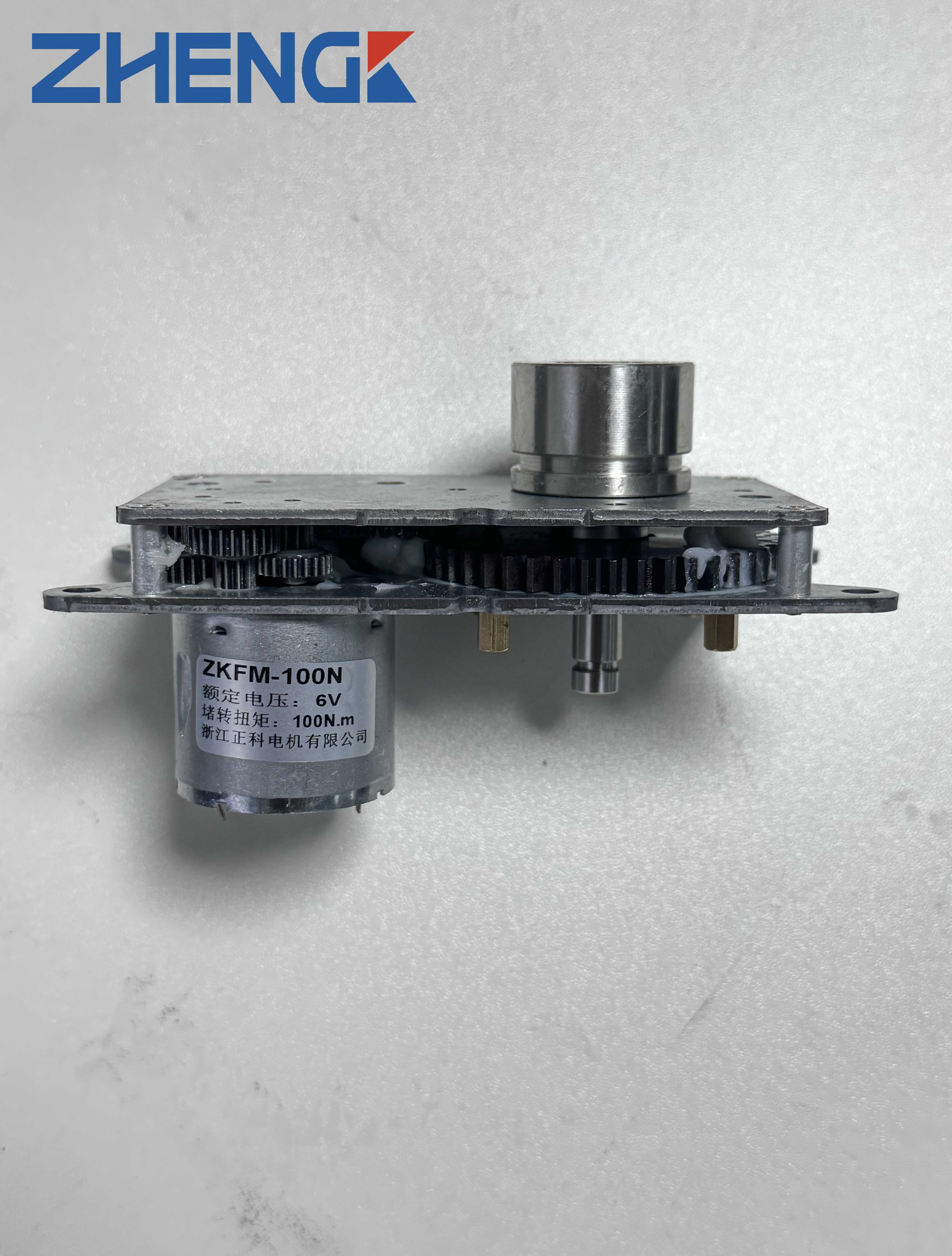

Planetary gear motorsare compact, have High Power density, are small and lightweight, and are highly efficient and precise. Its design virtually eliminates recoil and ensures precise motion control.

2. Excellent torque transmission

Planetary gear motors share the load through multiple planetary gears and perform particularly well in applications requiring High Torque. Its drive train delivers strong torque output in a stable manner for high load and high demand scenarios.

3. High reliability and long life

The planetary gear system has been carefully designed to minimize gear misalignment and vibration problems. Its low noise level, excellent repeatability and stable operating performance greatly enhance the reliability and durability of the motor for long-term operation.

Disadvantages:

1. Higher cost and complex design

Compared to other types of motors, planetary gear motors are usually more expensive because of their complex mechanical design and the high level of manufacturing precision required. In addition, maintenance may require more specialized technical support, resulting in higher overall costs.

2. Potential operating noise and maintenance difficulties

While planetary gear motors are typically quieter, vibration and noise may become more noticeable under high loads or complex operating conditions. In addition, their complex construction can present maintenance and repair challenges.