Common Motor Problems and How to Troubleshoot Them

Electric Motors may encounter issues during operation due to electrical, mechanical, or environmental factors. Identifying problems early helps reduce downtime and extend motor life.

Motor Does Not Start

1. Check whether the power supply voltage matches the motor rating.

2. Inspect wiring connections for looseness or poor contact.

3. For Brushed Motors, worn carbon brushes may prevent startup.

Excessive Noise or Vibration

1. Noise is often caused by misalignment or mechanical imbalance.

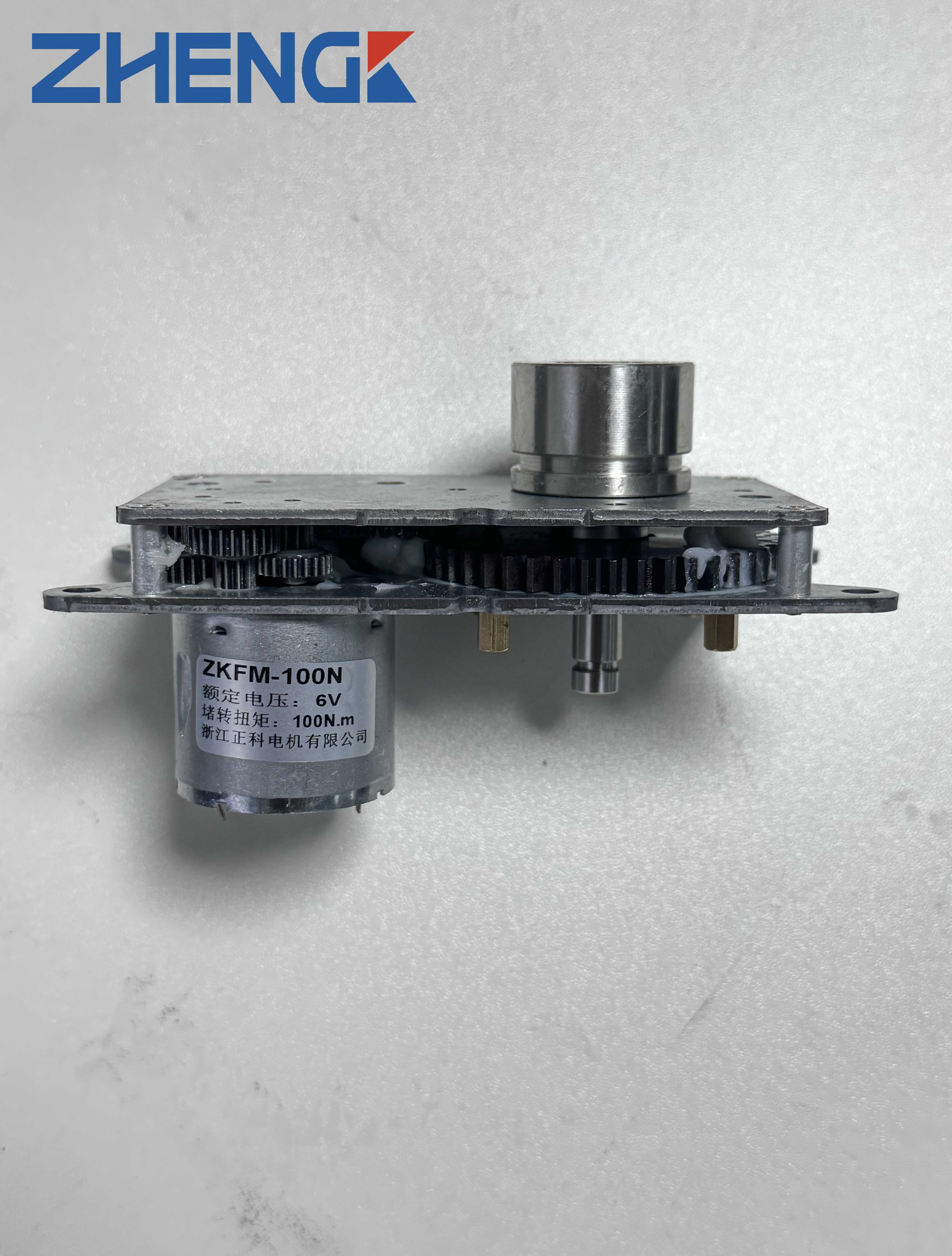

2. Worn bearings or gears can increase vibration levels.

3. Insufficient lubrication may also lead to abnormal noise.

Motor Overheating

1. Overloading is a common cause of temperature rise.

2. Poor ventilation can trap heat inside the motor.

3. Continuous operation beyond rated limits accelerates overheating.

Unstable Speed or Torque

1. Voltage fluctuation can cause speed instability.

2. Improper controller settings may affect torque output.

3. Mechanical resistance increases load on the motor.

Reduced Efficiency Over Time

1. Component wear increases internal friction.

2. Dust and moisture can degrade motor performance.

3. Lack of routine maintenance shortens service life.

Frequently Asked Questions

Q1: What causes motor noise in normal operation?

Improper installation, gear wear, or insufficient lubrication.

Q2: Why does my motor draw excessive current?

The load may exceed the motor’s rated capacity.

Q3: How can motor overheating be prevented?

Operate within rated limits and ensure proper ventilation.

Q4: When should a motor be replaced?

When repeated failures occur or internal damage is severe.