Differences Between DC and AC Motors

Electric motors are integral to various applications, from industrial machinery to household appliances. The two primary types are Dc Motors and AC motors. Each has distinct characteristics, advantages, and ideal use cases.

DC Motors

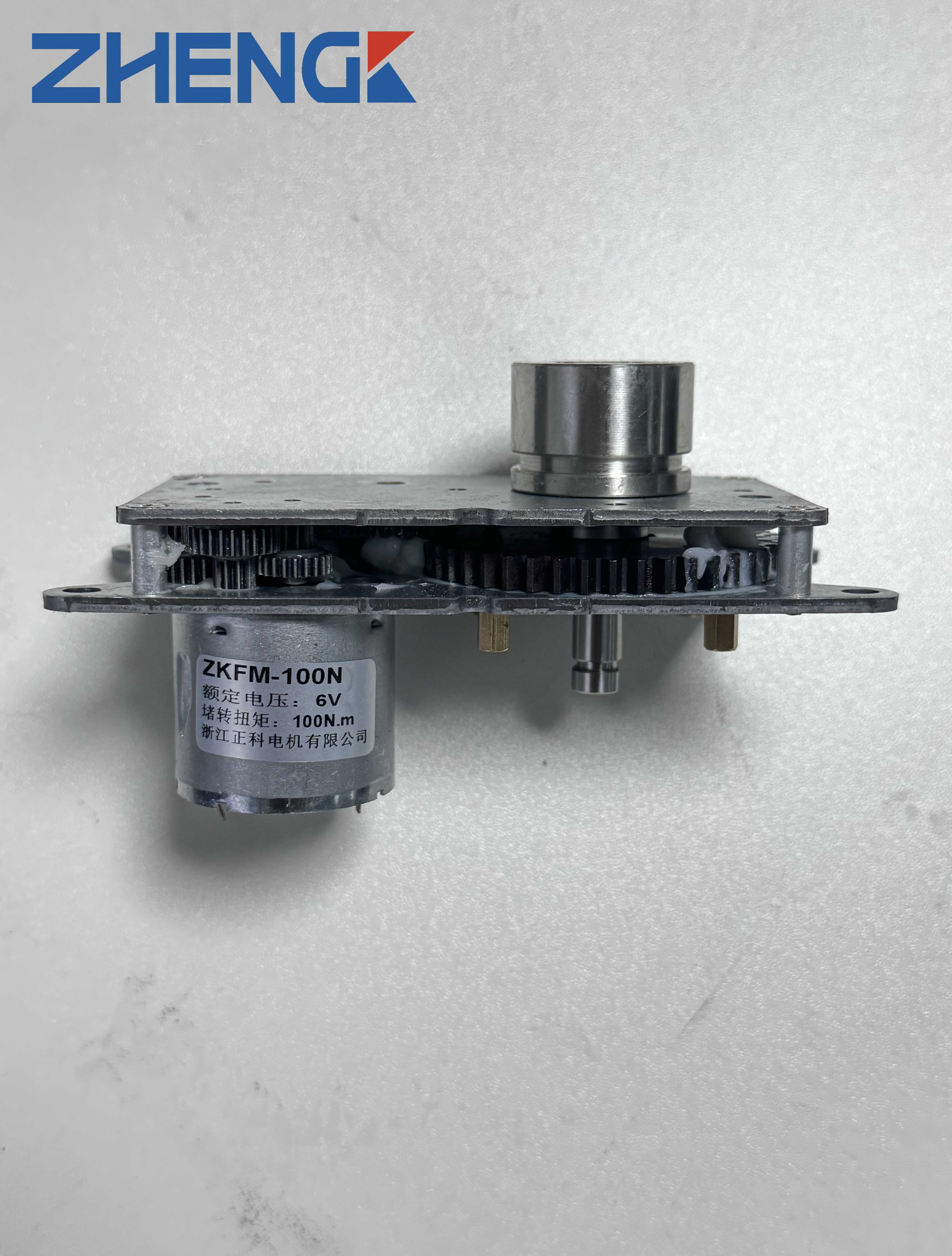

Operation: DC motors operate using direct current, where the current flows in a single direction. They typically consist of a stator providing a constant magnetic field and a rotor (armature) that rotates within this field.

Advantages:

High Starting Torque: DC motors can produce a starting torque up to 500% of their rated torque, making them suitable for applications like electric trains and cranes.

Precise Speed Control: They offer a wide range of speed control, both above and below the rated speed, through methods like armature voltage control and field flux control.

Quick Response: DC motors can start, stop, and reverse direction quickly, which is beneficial in applications requiring rapid changes.

Disadvantages:

Maintenance Requirements: The presence of brushes and commutators necessitates regular maintenance and can lead to increased operational costs.

Higher Initial Cost: DC motors generally have a higher initial cost compared to AC motors.

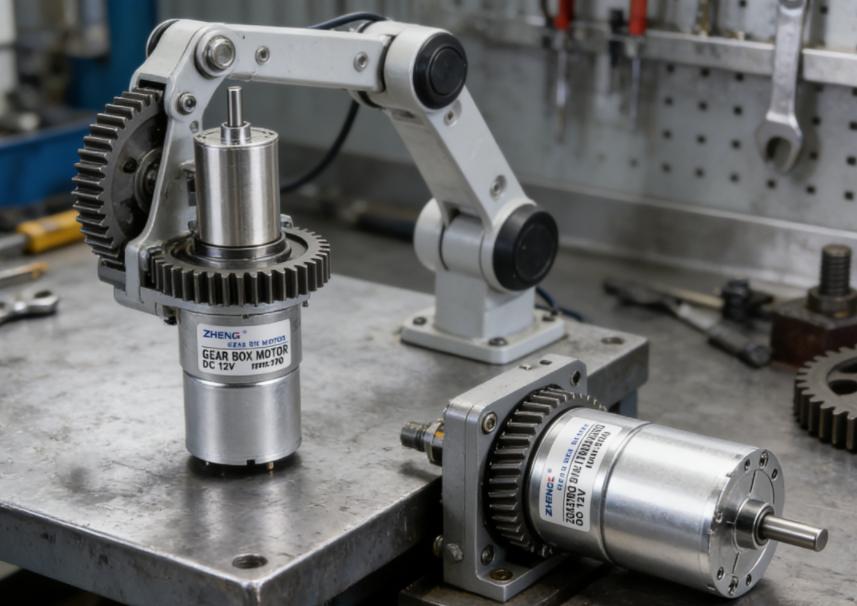

Common Applications: Printers, medical equipment, robots, smart homes, aircraft models, small machine tools, etc.

AC Motors

Operation: AC motors function using alternating current, where the current periodically reverses direction. They are commonly divided into synchronous and induction (asynchronous) motors.

Advantages:

Simple Design and Construction: AC motors have fewer components, making them easier to manufacture and maintain.

Cost-Effective: Generally more affordable than DC motors due to their simpler design.

High Efficiency: Particularly in Induction Motors, AC motors maintain high efficiency over a wide range of operating conditions.

Disadvantages:

Limited Speed Control: Controlling the speed of AC motors is more complex and often requires additional equipment like variable frequency drives.

Lower Starting Torque: AC motors typically have lower starting torque compared to DC motors, which can be a limitation in certain applications.

Common Applications: Industrial machinery (pumps, compressors, conveyors), household appliances (washing machines, fans), and HVAC systems.

Choosing between a DC and AC motor depends on the specific requirements of your application. If high starting torque and precise speed control are essential, a DC motor may be the preferred choice. For applications where cost-effectiveness and low maintenance are priorities, an AC motor could be more suitable.