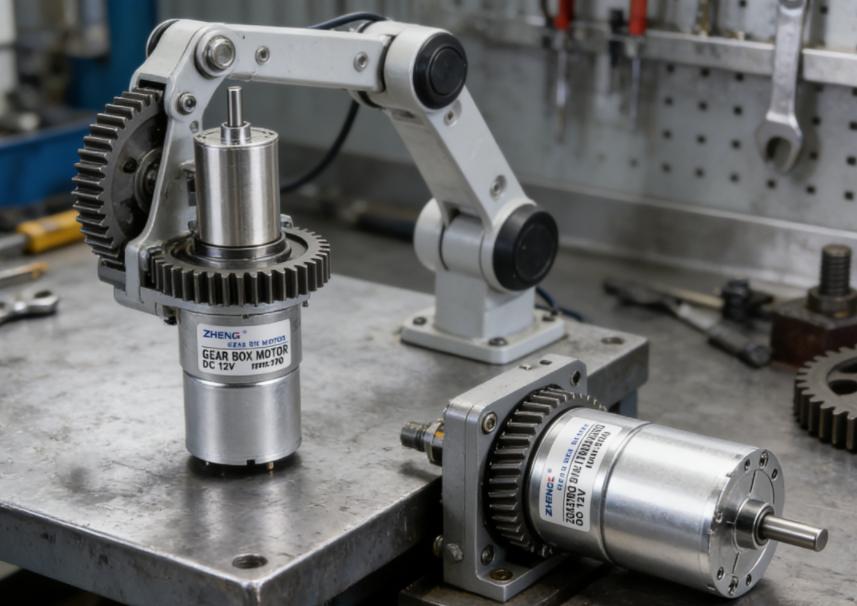

Essential Factors to Consider in Micro Motor Selection

When selecting a Micro Motor, recommendations can be made from multiple perspectives to ensure proper performance, compatibility, and long service life.

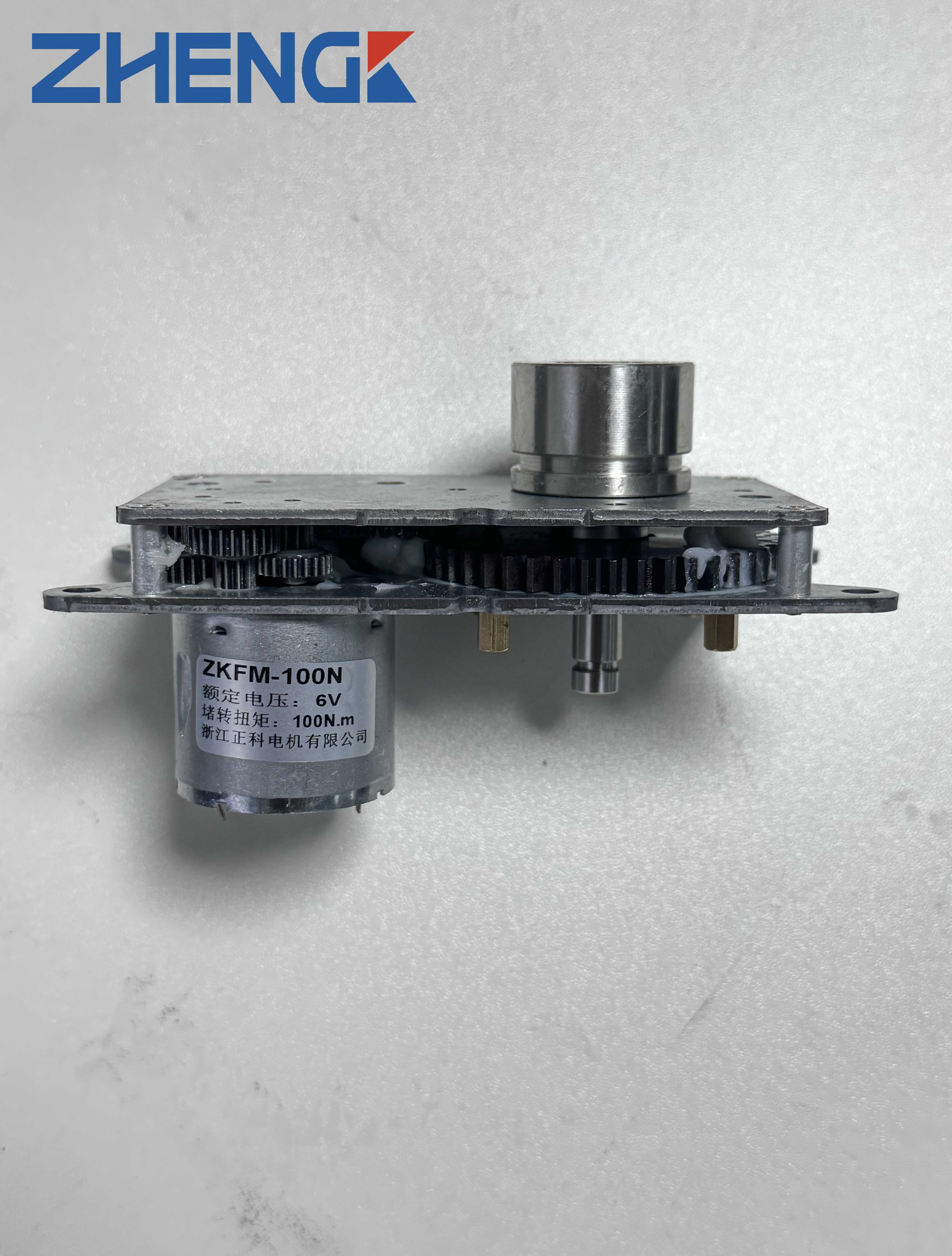

1. Mechanical Dimensions

The maximum allowable installation space should be clearly defined, including limits on diameter, length, and overall motor size.

Mounting screw specifications must be considered in advance, such as screw type, effective depth, and spacing.

The dimensions of the output shaft, flat shaft, set screw position, pin holes, and locating features should be evaluated during the product design stage to ensure full compatibility with the installation structure.

It is recommended to reserve slightly more assembly space, which allows greater flexibility in motor model selection.

2. Performance Selection

The required rated torque and speed should be determined first. If the target parameters are unclear, a finished motor available on the market can be tested as a reference. After validation, the working voltage and current should be provided to the supplier.

Maximum allowable current and torque must also be considered. Although higher torque may appear beneficial, excessive torque can damage the entire system, causing wear to mechanical structures and components, and ultimately reducing the service life of both the motor and the gearbox.

When selecting electrical performance, lower speeds and smaller reduction ratios are recommended to achieve higher strength, improved stability, and longer operational life.

3. Noise Considerations

Mechanical noise is often the primary concern in micro motor applications.

If excessive noise occurs after the motor is installed, possible causes should be analyzed, such as resonance caused by high rotational speed, vibration between the gearbox and surrounding mechanical structures, or noise generated by eccentric loads.

Material selection plays a critical role in noise control. Plastic gears generally produce less noise than metal gears, and helical gears operate more quietly than spur gears. Metal worm gear mechanisms and Planetary Gearboxes typically generate higher noise levels. High precision in design and manufacturing can effectively reduce overall noise.

Zhengke Motor has more than 20 years of experience in micro motor manufacturing and consistently follows a quality-first and low noise design philosophy. The company provides customized motor solutions and is committed to delivering products with optimal performance and reliable quality.