Future Directions for Electric Motors

With the rapid development of artificial intelligence (AI), the Internet of Things (IoT), and other technologies, as well as the advancement of global carbon neutrality goals, the motor industry is experiencing a comprehensive transformation from traditional power drive to intelligent, efficient, and green. As the core component of automation and intelligence, the application field of micro-motor has been expanded from conventional industry to emerging fields such as home appliances, automobiles, medical care, modern agriculture, logistics, etc., which has become an important force to promote the change of social productivity. The following are the four core directions for future motor development:

- The deep integration of intelligence and AI

The introduction of AI technology enables the motor system to have self-learning, self-adaptation, and predictive maintenance capabilities. For example:

- Intelligent control algorithms: optimize motor operating efficiency and reduce noise and vibration through high-frequency injection algorithms, weak magnetism algorithms, etc. (e.g., solutions from Peak Work Technology).

- Remote monitoring and cloud platform: MetaOne cloud tuning tool launched by MetaCore integrates development, simulation and compilation functions to help engineers quickly debug and achieve real-time monitoring of motor status and parameter optimization.

- Failure prediction and health management (PHM): using sensors and AI models to identify potential failures in advance and extend equipment life (e.g. smart motors in Industry 4.0).

- Energy efficient technology breakthroughs

Driven by the goal of “double carbon”, high efficiency and energy saving has become the core demand of motor design:

- Permanent Magnet Motor: adopting rare earth permanent magnet material, realizing high power density and low loss, widely used in new energy vehicles (e.g. Tesla drive motor).

- Inverter drive technology: reduce energy consumption by adjusting the Motor Speed to match the load demand (e.g. inverter air conditioners and washing machines in the field of home appliances).

- Popularization of IE4/IE5 energy-efficiency standards: the global market demand for ultra-high-efficiency motors is surging, and IE4 motors may become mainstream in 2025, promoting energy-efficiency improvement in the industrial field.

- The expansion of multi-field application scenarios

Micro-motor "small but strong" characteristics promote its penetration in a number of emerging fields.

- New energy vehicles: permanent magnet motors dominate the drive system, vehicle-grade chips meet the needs of electronic fans, air conditioning blowers, etc., and the market compound growth rate of more than 20%.

- Smart Home: BLDC motors are used in floor-sweeping robots and smart fans, combined with Wi-Fi/Bluetooth to realize remote control.

- Medical equipment: micro stepper motors used in surgical robots, portable diagnostic instruments, requiring high precision and low noise.

- Modern agriculture: automated irrigation systems, warehousing, and logistics robots rely on highly reliable servo motors.

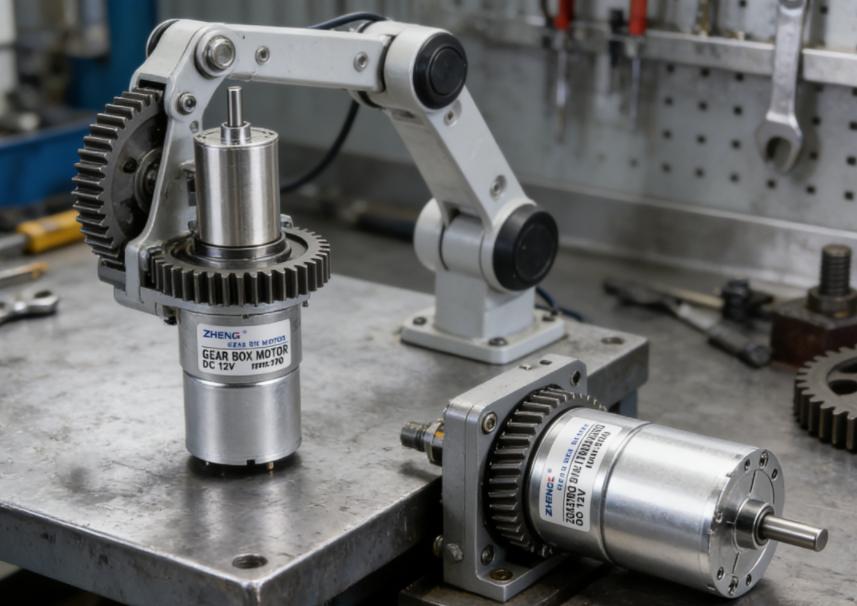

- Industrial automation: collaborative robots and AGV carts use brushless DC motors to improve production line flexibility.

- Green Manufacturing and Sustainable Development

From material to recycling, the whole life cycle of the motor is green:

- Eco-friendly material application: Adopt recyclable insulation materials and rare-earth-free magnets (e.g., ferrite permanent magnets) to reduce dependence on scarce resources.

- Lightweight design: Reduce motor weight and improve energy efficiency through topology optimization and 3D printing technology (e.g. drone motors).

- Circular economy model: Promote motor remanufacturing and laddering utilization to reduce e-waste (e.g. EU WEEE directive).

The competitiveness of future motors will depend on the three core elements of “intelligence, high efficiency, and green”. Enterprises need to accelerate technological innovation, such as the layout of AI drive control, explore new materials, and deepen the synergy with downstream industries (e.g., new energy, and intelligent manufacturing). At the same time, the dual drive of policy support (e.g. energy efficiency subsidies, carbon tax mechanism) and market demand will further unleash the growth potential of the electric motor industry and drive it to become a key engine for global industrial upgrading.