How to Choose a DC Motor: A Comprehensive Guide and Scenario-Based Selection Strategy

As a core drive component in industrial automation, consumer electronics, medical equipment and other fields, the performance of DC motorsis directly related to the efficiency, reliability and service life of the equipment. However, in the face of a wide variety of Dc Motor Products on the market with complex parameters, how to accurately select the type according to the actual needs has become a key challenge for engineers and technical decision makers. This article will start from the basic principles of DC motors, combined with typical application scenarios, systematically explain the selection method, key parameters analysis and common misconceptions, to help you make scientific decisions.

1. Basic types and characteristics of DC motor

1.1 Brushed DC motor

- Principle: Realize current commutation through mechanical contact between brush and commutator, simple structure and low cost. Advantages: large starting torque, low cost.

- Advantages: large starting torque, easy speed regulation, suitable for low-cost scenarios.

- Disadvantages: Short life time due to brush wear (usually 500-2000 hours), prone to electromagnetic interference.

- Typical applications: household appliances (vacuum cleaners, power tools), toys, small conveyor belts.

1.2 Brushless DC motors

- Principle: contactless control by using electronic commutators (e.g. Hall sensors) instead of mechanical brushes.

- Advantages: long life (more than 10,000 hours), high efficiency (85%-95%), low noise. Disadvantages: requires matching driver, initial cost.

- Disadvantages: Requires matching driver, high initial cost.

- Typical applications: drones, precision instruments, electric vehicles, industrial robots.

1.3 Stepping motor

- Principle: control angular displacement by pulse signal, can realize open-loop position control.

- Advantages: high positioning accuracy (±0.1°), no encoder feedback.

- Disadvantages: poor high-speed performance, easy to lose steps, large heat.

- Typical applications: 3D printers, CNC machine tools, automation instruments.

1.4 Servomotor

- Principle: integrated encoder to form closed-loop control, real-time adjustment of speed and position.

- Advantages: fast dynamic response, high precision (± 0.01mm), strong overload capacity.

- Disadvantages: high system complexity, significant increase in cost.

- Typical applications: robotic arms, high-precision CNC equipment, aerospace devices.

2. Selection Analysis

2.1 Voltage and Current

- Rated voltage: need to match the power system (such as 12V, 24V, 48V). Too low a voltage will lead to insufficient torque, too high may burn the winding.

- Rated current: determine the power consumption and heat generation of the motor, to ensure that the maximum current carrying capacity of the power supply circuit.

2.2 Torque Characteristics

- Starting torque (Stall Torque): the maximum output torque of the motor in the blocked state, determines whether it can overcome the load inertia.

- Continuous Torque: the safe torque range for long-term operation, which should be higher than the actual load demand.

- Torque-Speed Curve: Reflects the torque decay of the motor at different speeds, which should be matched with the load characteristics.

2.3 Speed Range

- No-Load Speed: The maximum speed of the motor without load, usually proportional to the voltage.

- Rated Speed: The actual working speed with rated load, which should meet the requirement of equipment operation efficiency.

2.4 Efficiency and temperature rise

- Efficiency: the ratio of output mechanical power to input electric power, which directly affects the energy consumption. Brushless motor efficiency is usually 15%-20% higher than brush motor.

- Temperature rise limit: Insulation level (e.g. B class 130℃, F class 155℃) determines the maximum allowable working temperature of the motor, and heat-resistant models should be selected for high temperature environments.

2.5 Environmental adaptability

- Protection Rating (IP Rating): e.g. IP54 (dustproof and waterproof splash-proof) is suitable for general industrial environments, and IP67 (dustproof and waterproof immersion) is suitable for outdoor or humid scenarios.

- Vibration and Shock Resistance: Vehicle-mounted, aerospace equipment requires the selection of a reinforced structure.

3. Application Scenarios and Selection Strategies

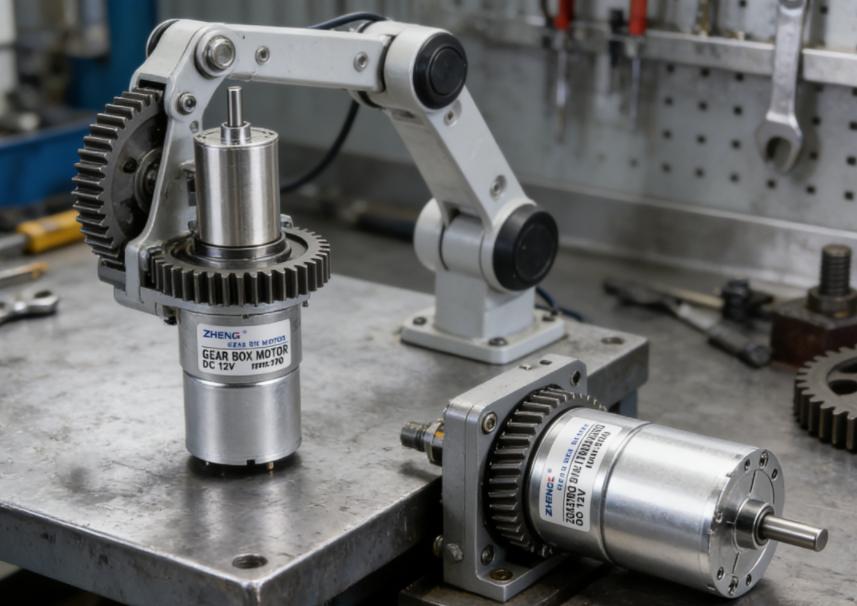

3.1 Industrial automation equipment

- Demand characteristics: high reliability, long life, continuous operation.

- Recommended type: brushless DC motor or servo motor.

- Key parameters:

- Torque: Need to cover the peak load when the equipment starts (e.g. resistance when the conveyor belt is blocked).

- Protection level: IP54 or above is recommended for dusty environment in workshop.

- Control mode: PLC or bus communication (e.g. CANopen, EtherCAT) should be supported.

3.2 Medical equipment

- Required features: low noise (<40dB), high precision, sterile environment compatibility.

- Recommended type: brushless DC motor or micro stepping motor.

- Key parameters:

- Material: the housing needs to be certified for biocompatibility (e.g. ISO 13485).

- Electromagnetic compatibility (EMC): Avoid interference with sensitive medical electronic equipment.

3.3 Smart Home and Consumer Electronics

- Requirement characteristics: miniaturization, low power consumption, cost-sensitive.

- Recommended types: brushed DC motors or micro brushless motors.

- Key parameters:

- Power consumption: Battery-powered devices need to choose a model with a standby current of <1mA.

- Size: e.g. micro motors with a diameter of ≤20mm are suitable for smart curtains and camera heads.

3.4 New Energy Vehicles

- Required features: high power density, high temperature resistance, vibration resistance.

- Recommended type: permanent magnet brushless DC motor.

- Key parameters:

- Efficiency: >90% to extend range.

- Heat dissipation design: liquid-cooled or forced air-cooled structure.

4. Selection Steps and Tools

4.1 Demand analysis list

- Load characteristics: load type (constant torque, variable torque), inertia, whether frequent start-stop is required. 2.

- control requirements: speed range, positioning accuracy, type of feedback signal (encoder, Hall sensor).

- Environmental conditions: temperature, humidity, dust, corrosive gases. 4.

- Power and space limitations: available voltage, installation size, weight limitations.

4.2 Parameter Calculation Example

Assume an automated conveyor line selection:

- Load torque: Calculate belt friction torque + acceleration moment of inertia = 0.5Nm.

- Factor of safety: Increase margin by 20% → 0.6Nm.

- Speed requirement: Belt line speed 1m/s, drum diameter 50mm → speed ≈ 382 RPM.

- Selection result: choose a brushless DC motor with rated torque of 0.65Nm, rated speed of 400 RPM, and IP55 protection case.

4.3 Supplier Evaluation Dimensions

- Technical capability: whether to support customized design (such as special shaft extension, flange mounting).

- Test report: provide third party certification (CE, UL) and life test data.

- Service support: whether to provide 3D model, technical selection software or on-site commissioning services.

5. Common Selection Misconceptions and Avoidance Methods

5.1 Misunderstanding 1: excessive pursuit of high torque

- Problem: Selecting a motor with torque much higher than the actual demand will lead to higher costs and lower efficiency.

- Solution: Accurately calculate the load torque, reserve 10% -20% safety margin can be.

5.2 Misunderstanding two: ignore the environmental factors

- Problem: Ordinary motors are easy to fail in high temperature or humid environment.

- Solution: Define the working environment and choose the corresponding protection level and insulation material.

5.3 Misunderstanding 3: Neglecting system compatibility

- Problem: The motor does not match with the driver and reducer, resulting in abnormal control.

- Solution: Ask the supplier to provide a complete set of drive programs or compatibility list.

6. Maintenance and life optimization recommendations

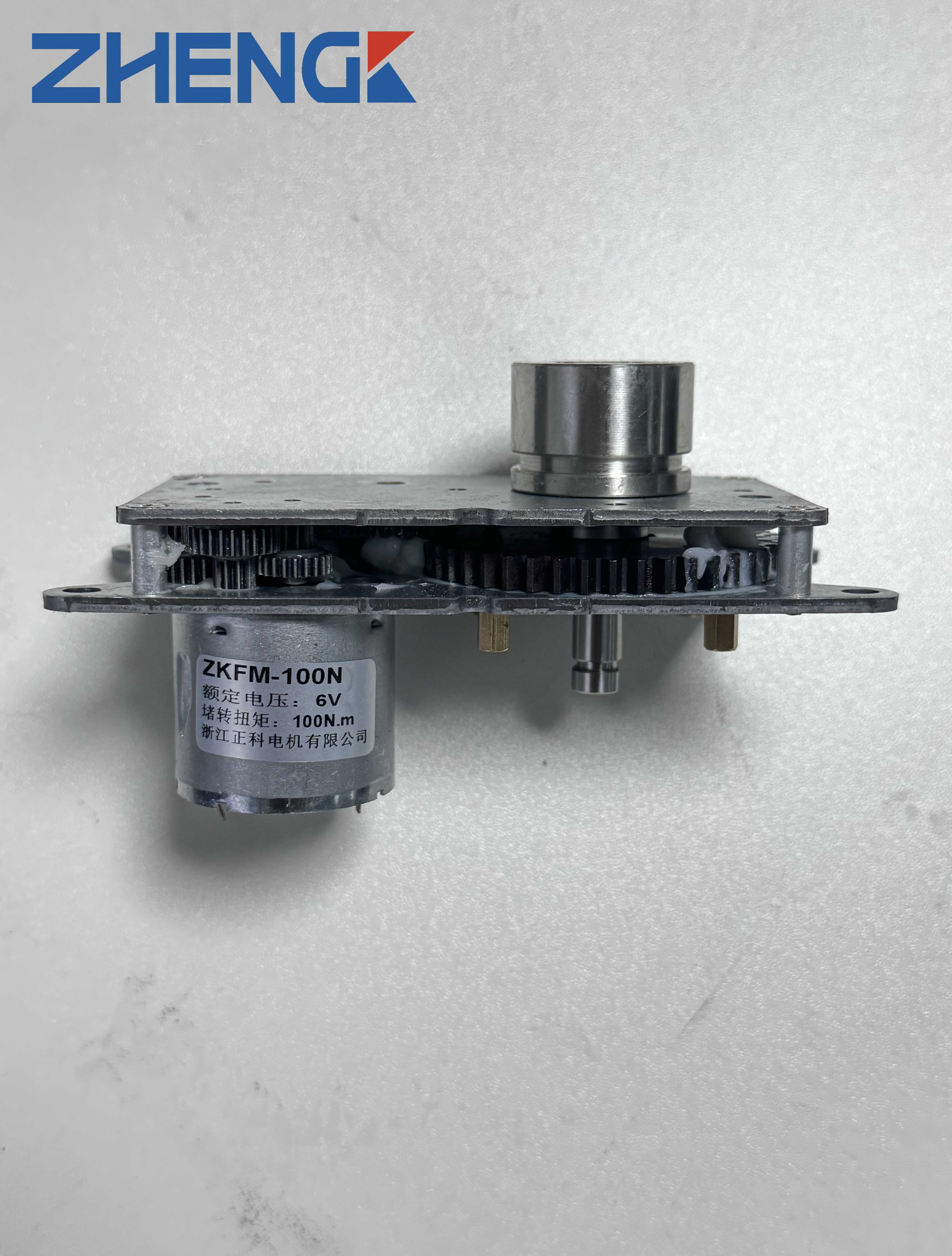

- Regular lubrication: gear box every 6 months to replenish high temperature resistant grease (such as Molykote EM-50L).

- Brush Maintenance: Brush motors should be checked for brush wear every 500 hours with a replacement threshold of 1/3 of the original length.

- Heat dissipation management: Ensure good ventilation, avoid blocking heat sinks, and add heat sinks for high temperature environments.

- Vibration monitoring: use vibration sensors to check the bearing status regularly, abnormal noise needs to be investigated in time.