How to Increase the Speed of Micro Motors

Micro Motors are essential components in a wide variety of applications, from medical devices and robotics to consumer electronics and automotive systems. These small, powerful motors are designed to deliver high performance in tight spaces, but often, designers and engineers face the challenge of maximizing their speed while maintaining efficiency, reliability, and longevity. Whether you're working with brushed or brushless DC motors, increasing the speed of micro motors involves a combination of design modifications, control techniques, and material improvements.

Before diving into speed-increasing methods, it's important to first understand what micro motors are and how they function. Micro motorsare small, lightweight motors that deliver High Torque and speed relative to their size. They are commonly found in a wide range of devices, such as:

- Medical instruments (e.g., surgical tools, sensors)

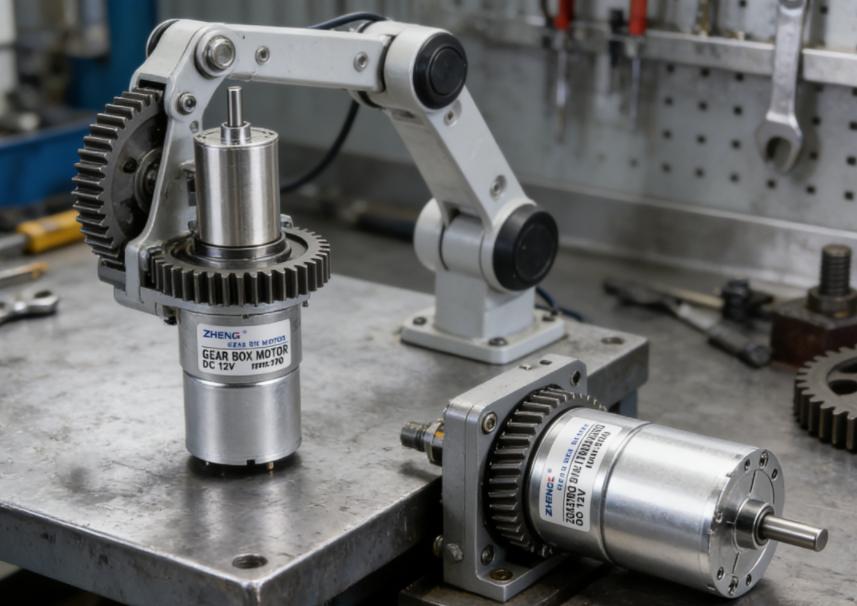

- Robotic systems (e.g., robotic arms, drones)

- Consumer electronics (e.g., cell phones, cameras)

- Automotive applications (e.g., windshield wipers, power windows)

- Toys and hobby electronics (e.g., RC cars, drones)

Micro motors are usually classified based on their power source and design type:

- Brushed DC motors – traditional and simple but may have wear issues.

- Brushless DC motors (BLDC) – more efficient, with no brush wear.

Key Factors That Influence the Speed of Micro Motors

- Power Supply Voltage and Current

In micro motors, the applied voltage and current directly influence the motor speed. For DC motors, the speed is proportional to the input voltage, while the torque is influenced by the current.

- Increasing voltage increases the speed of a DC motor, but only up to a point where the motor's components can handle the additional load without overheating or suffering damage.

- Current flow must also be optimized. Too much current can cause excessive heat, while too little current can result in underperformance.

- Magnetic Field Strength

The speed of a motor is also determined by the strength of the magnetic field produced by the stator. A stronger magnetic field can induce higher rotational speeds. This can be achieved through better permanent magnets, winding designs, or more powerful stators.

- For brushed DC motors, improving the strength of the magnetic field can increase speed by reducing the load on the rotor.

- For BLDC motors, optimizing the motor’s stator and rotor design with high-quality materials such as neodymium magnets can enhance performance.

Methods to Increase the Speed of Micro Motors

- Optimize the Voltage Supply

One of the most effective ways to increase the speed of a micro motor is to increase the supply voltage. The speed of a DC motor is proportional to the applied voltage, so higher voltage results in a higher speed. However, it’s important to balance voltage with other factors such as motor temperature and efficiency.

- Power supply selection: Ensure that the power supply is capable of providing consistent and stable voltage without causing voltage spikes that could damage the motor. A regulated power supply is recommended.

- Voltage ripple: Minimize voltage ripple (variations in the output voltage) by using proper filtering to maintain consistent motor speed.

- Use a Higher-Performance Motor

When speed is a critical factor, sometimes the best solution is to upgrade the motor. Not all micro motors are created equal, and many are designed with specific performance characteristics in mind, such as torque or precision rather than speed. For example:

- Brushless DC motors (BLDC) are typically faster and more efficient than brushed DC motors. The absence of brushes reduces friction and wear, allowing the motor to operate at higher speeds.

- Coreless motors are another excellent option when high speed is required. These motors eliminate the iron core found in traditional motors, reducing the motor’s inertia and allowing for quicker acceleration.

- Improve Motor Cooling

Increasing motor speed can generate significant amounts of heat, which can damage motor components and reduce performance. To mitigate this, it's essential to maintain an optimal operating temperature. Several cooling techniques can be employed to improve the thermal performance of a micro motor:

- Passive cooling: Use materials that dissipate heat quickly, such as heat sinks and thermal management coatings.

- Active cooling: In some cases, using small fans or air circulation systems can help prevent the motor from overheating, especially in high-speed applications.

- Upgrade the Motor Windings

The windings in a DC motor play a crucial role in determining its maximum speed. By reducing the number of turns in the motor's winding, you can reduce the motor's inductance, which allows for faster motor response and higher speeds.

- High-conductivity wire: Using high-quality wire with low resistance can reduce power losses and improve motor performance.

- Winding configuration: Some motor types allow for modifications to the winding configuration, such as the number of turns per coil or the gauge of wire used, which can influence both the motor’s speed and torque characteristics.

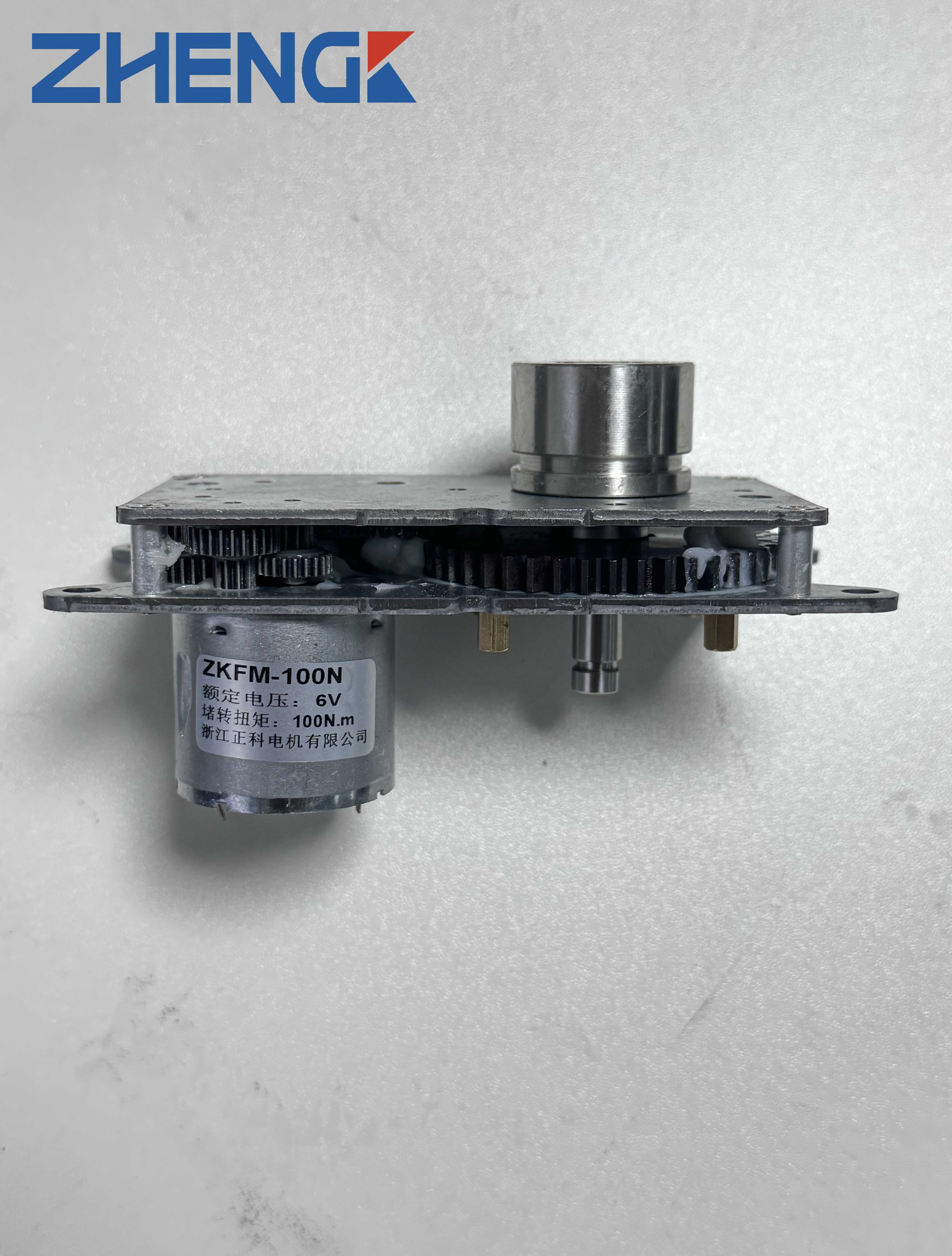

- Employ Gear Ratio Optimization

Sometimes, increasing the speed of the motor itself may not be the best option if it compromises the motor’s torque output. Instead, gearing can be used to trade off torque for speed. Lower gear ratios increase the motor’s speed by reducing the load on the motor, but this comes at the cost of torque.

- Gearhead motors: Use a gearbox to increase output speed while controlling the torque output, especially in precision applications.

- Minimize Friction and Load Resistance

Reducing frictional losses and mechanical resistance is crucial when trying to increase the speed of a micro motor. Some key ways to achieve this include:

- Bearings: Using high-quality, low-friction bearings can significantly reduce the mechanical resistance in the motor, allowing for higher speeds.

- Lubrication: Proper lubrication of moving parts can reduce friction and wear, contributing to better motor performance at higher speeds.

While increasing motor speed is often desirable, it comes with its own set of "challenges":

- Heat generation: Higher speeds often lead to more heat, which can damage the motor if not properly managed.

- Mechanical stress: Increasing the speed can result in increased mechanical stress on motor components, which may lead to wear and tear over time.

- Power consumption: At higher speeds, the motor will consume more power, which can be a concern in battery-powered applications.

- Noise and vibration: High-speed motors tend to generate more noise and vibration, which may not be suitable for certain applications.

If you need assistance with selecting the best motor for your specific application or require further guidance on implementing these techniques, feel free to contact us for expert advice.