Introduction to Gearmotors for Efficient Power Transmission

In modern industrial and technological applications, geared motors, as a core component of the power system, have become a key technology for improving equipment efficiency and optimizing energy use due to their unique design and performance advantages. Whether it is heavy-duty industrial equipment or precision automation devices, the reasonable selection and application of Geared Motors directly affects the reliability and economy of the system. This article will analyze the performance advantages, application scenarios and selection strategies of geared motors to provide engineers and technical decision makers with a comprehensive reference guide.

1. The core performance advantages of geared motors

1 High-efficiency torque amplification and precise speed regulation

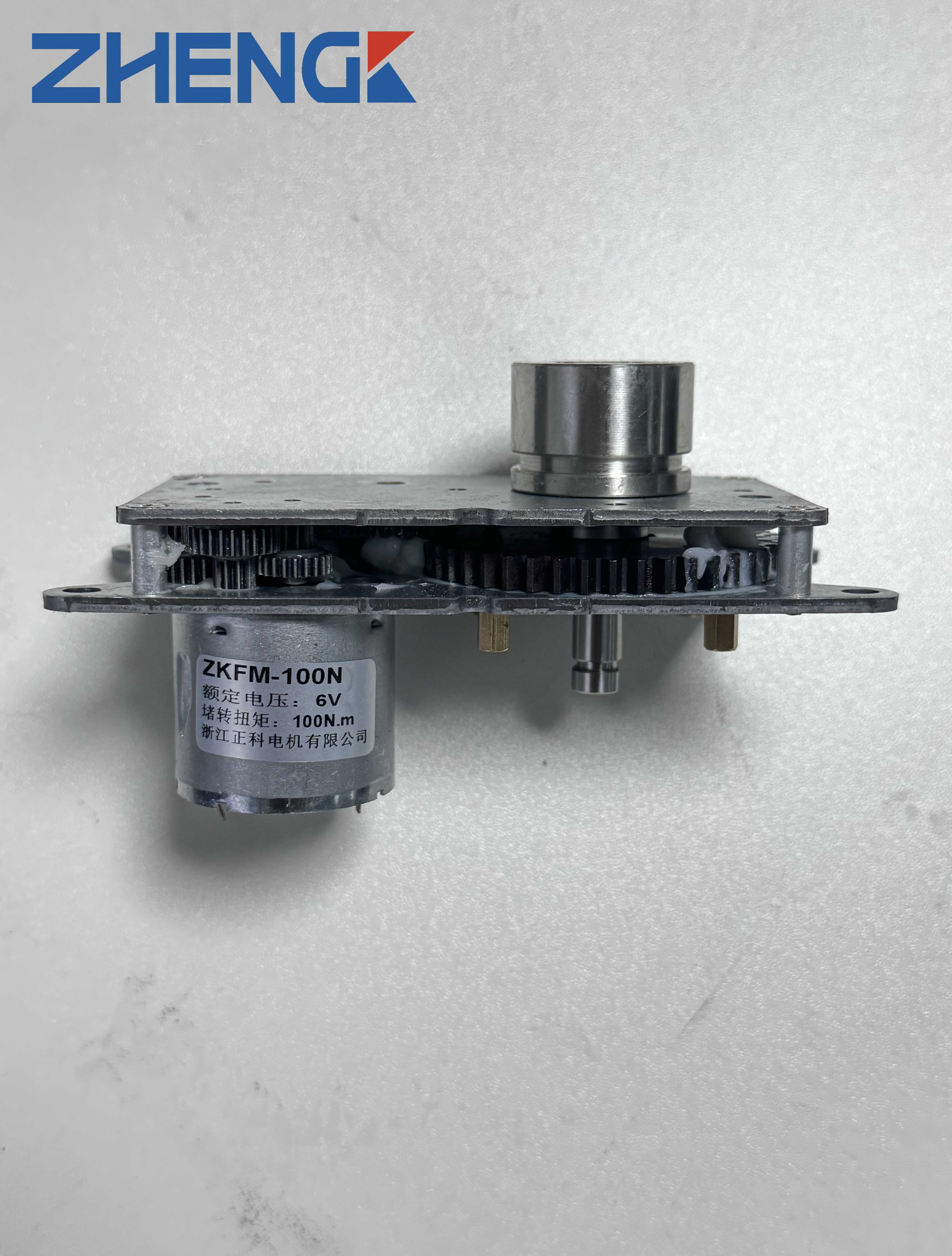

Through the mechanical deceleration of the gearbox, the geared motor converts the high speed and low torque output of the motor into low speed and High Torque power. Its torque amplification can reach tens or even hundreds of times the input torque, for example, a motor with a rated torque of 1Nm with a 10:1 gearbox can increase the output torque to 10Nm. this feature makes it perform well in scenarios that require a large load to start up or sustained heavy-duty operation.

2 Improved system efficiency and energy savings

The gearbox's transmission structure optimizes the motor's operating point so that it operates in the high-efficiency zone. For example, an ordinary motor may have an efficiency of less than 50% at low speeds, whereas a gearmotor can maintain an efficient speed range of 80%-90% after gear reduction, thus reducing overall energy consumption.

3 Compact structure and space optimization

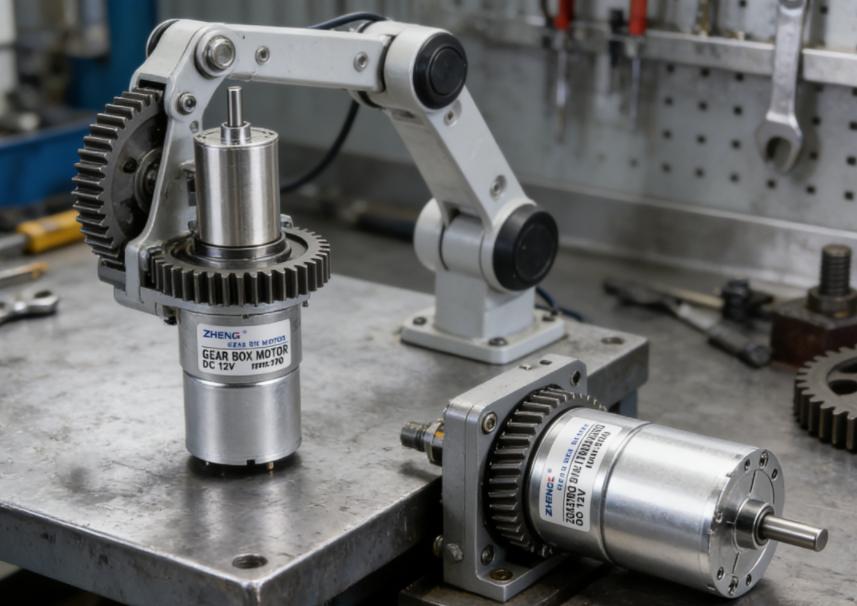

The integrated design of the geared motor combines the motor and gearbox into one, significantly reducing the installation space. Planetary Gear Motors, for example, can be limited to a diameter of 50mm or less, but can output up to 100Nm of torque, making them suitable for space-constrained robotic joints or medical equipment.

4 High reliability and long life

High-quality gear motor adopts high-precision bearing and sealing structure, for example:

- Gear hardness: surface hardness up to HRC58-62, wear resistance increased by more than 3 times.

- Protection grade: IP65 and above design can resist dusty and humid environment.

- Lubrication design: Lifetime maintenance-free grease or oil bath lubrication system extends the service life to more than 20,000 hours.

5 Low noise and smooth operation

Through precision gear processing (such as gear grinding process) and vibration-damping design, gearmotor operation noise can be lower than 60dB. For example, helical gearmotor noise is 15%-20% lower than spur gear, which is suitable for medical or office equipment with strict requirements on silence.

2. The applicable scenes and technology matching of geared motors

1 Industrial automation and production line

- Conveyor belt drive: high-torque geared motors (e.g. worm gear type) need to be matched to overcome start-up inertia.

- Robotic arm joints: adopting precision planetary gearheads with a repeat positioning accuracy of ±0.1mm.

2 Robots and collaborative machinery

- AGV carts: equipped with hollow shaft geared motors to directly drive the wheel hub and integrate encoder feedback.

- Service robots: micro harmonic gear motor realizes 0.01° level angle control.

3 New energy and environmental protection equipment

- Wind turbine pitch system: high-power planetary gearboxes withstand extreme wind load impacts.

- Solar tracking bracket: worm gear motor realizes daily angle fine-tuning at 0.1° level.

4 Medical and laboratory equipment

- CT machine rotating frame: low backlash planetary gearbox ensures imaging without motion artifacts.

- Liquid pumping system: Micro gear motor realizes 0.1mL level accurate flow control.

5 Smart Home and Consumer Electronics

- Intelligent curtain motor: DC gear motor with Hall sensor to realize silent start/stop.

- Kitchen Appliances: Gear motor drives high-torque cutter head of juicer and blender.

Maintenance and Failure Prevention

1 Daily maintenance points

- Vibration monitoring: use acceleration sensors to detect abnormal vibration of the gearbox (threshold recommended ≤ 4.5mm/s).

- Seal check: Clean the ventilation holes regularly to prevent oil leakage due to aging of oil seals.

2 Common fault diagnosis

①Failure phenomenon: abnormal noise

Possible causes: gear wear / insufficient lubrication

Solution: replace the gear or supplement grease

②Fault phenomenon: high temperature rise

Possible causes: overload or poor heat dissipation

Solution: check the load and improve ventilation

③Fault phenomenon: output shaft stalling

Possible causes: bearing damage or foreign body intrusion

Solution: clean the internal or replace the bearing