Micro Motor Selection Guide

Choosing the right micro motorcan feel like finding a needle in a haystack. With so many specifications, types, and brands, it’s easy to get overwhelmed. You're not just looking for a component; you're looking for reliability, efficiency, and a partner for your project's success. This practical Micro Motor Selection Guide is here to simplify the process, helping you make an informed decision step-by-step.

Step 1: Define Your Core Requirements

Before diving into product catalogs, clearly outline what you need. This saves time and prevents costly mismatches.

Load & Torque: What is the required starting and running torque? Always add a 20-30% safety margin.

Speed (RPM): Do you need high rotational speed or higher torque at a lower speed?

Voltage & Current: What is your power supply? Determine the operating voltage and the expected current draw.

Physical Size & Mounting: The micro motor must fit within your design constraints. Note the required dimensions, shaft type, and mounting style.

Duty Cycle: Will it run continuously, intermittently, or only in short bursts?

Step 2: Understand the Main Types of Micro Motors

Different technologies serve different purposes. Here’s a quick breakdown:

Brushed Dc Motors:The classic choice. They offer simple speed control, are cost-effective, and are excellent for variable load applications. Think of automotive accessories, conveyor systems, or basic DIY projects.

Brushless DC (BLDC) Motors: More advanced, with higher efficiency, longer life, and minimal maintenance. Ideal for applications where reliability, compact size, and heat management are critical, such as medical devices, drones, and precision instruments.

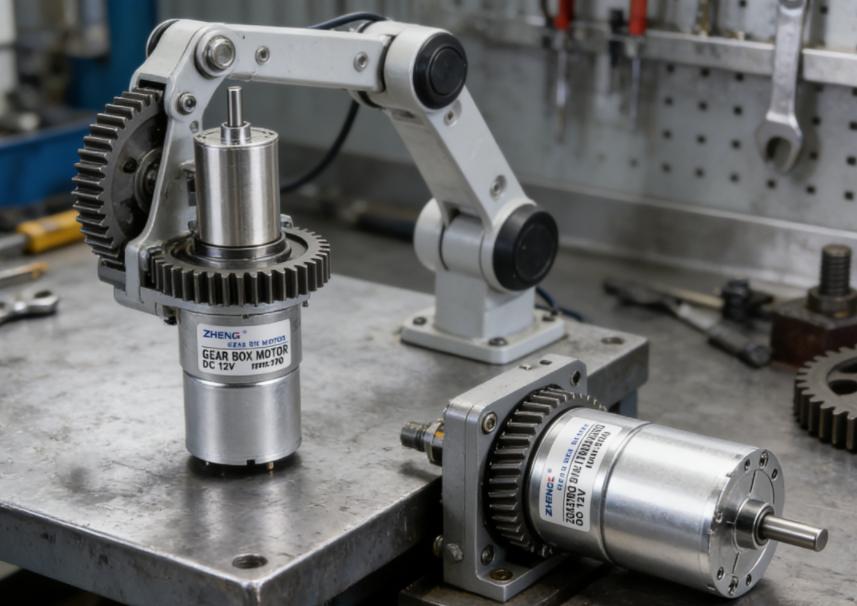

Gear Motors (Reduction Motors): When you need more torque at a lower output speed. A planetary gear motor, in particular, offers superior efficiency, higher torque density, and excellent durability in a compact package, perfect for robotics, automation equipment, and smart home actuators.

Step 3: Match Your Needs with the Right Technology

Now, let's connect the dots. This is where a supplier with a broad portfolio becomes invaluable.

For simple, cost-sensitive applications requiring basic variable speed, a Brushed DC Motor is often sufficient.

If your design demands long life, high efficiency, and precise control in a small package, focus your search on Brushless DC Motors.

When your primary need is high torque at low RPMs, like in a robotic joint, a smart lock, or a payment terminal, a Gear Motor is the answer. For the most demanding requirements regarding torque, stiffness, and smooth operation, a planetary gearbox paired with a micro motor is the premium solution.

Why Zhengke Motors Are a Strategic Choice for Engineers & Buyers

When evaluating suppliers, consider more than just the unit price. Total cost of ownership, support, and reliability are key. This is where Zhengke stands out as a strategic partner for your micro motor needs.

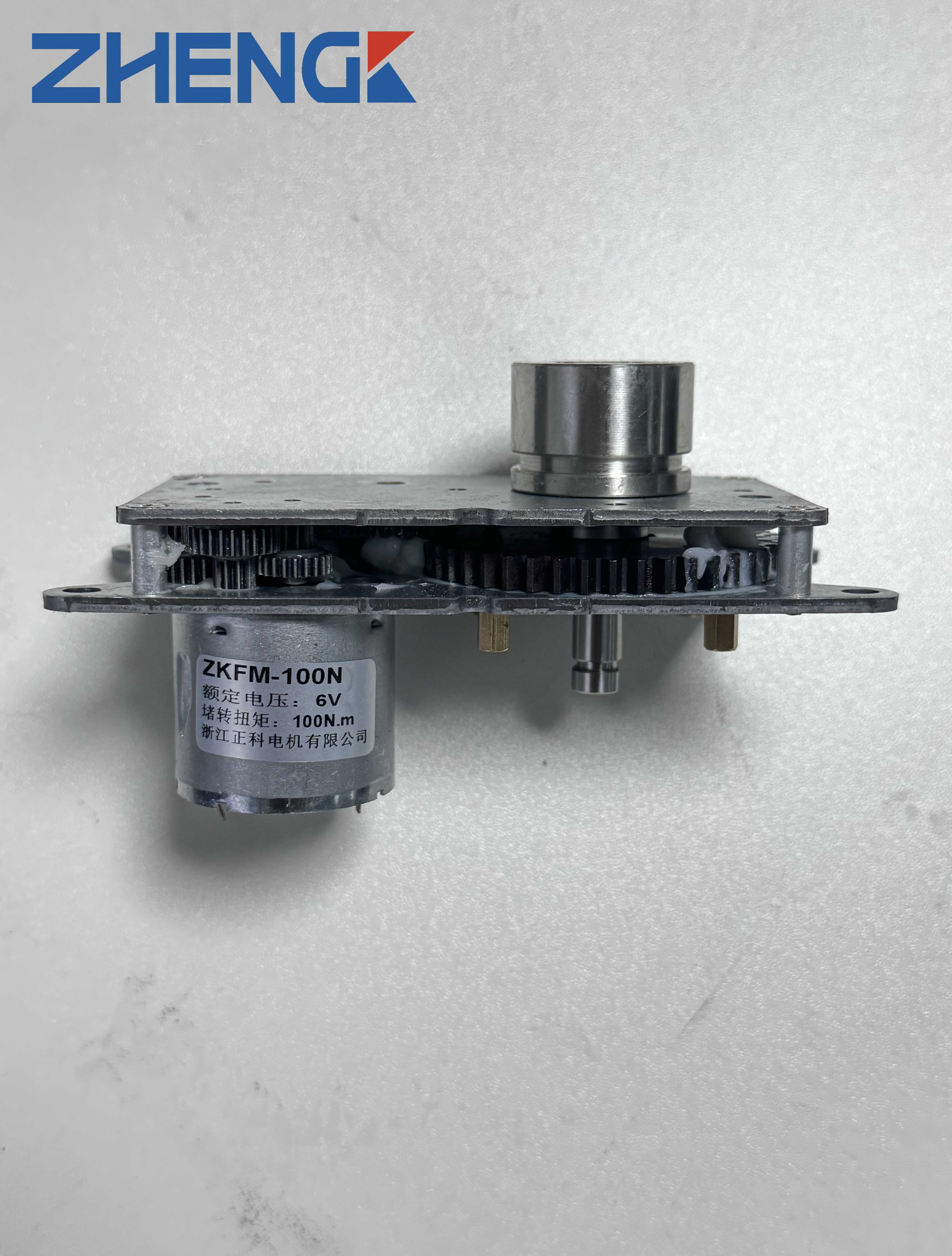

Zhengke offers a comprehensive range that directly maps to the selection guide above, from coreless and iron-core DC motors to sophisticated BLDC motors and a wide variety of reduction motors, including robust planetary gear motors.

What makes Zhengke a practical choice for your business?

Application-Led Design: Their motors are engineered to solve real-world problems in industries like automotive, smart home, healthcare, and consumer electronics. Whether you need a compact motor for a beauty device or a high-torque, quiet solution for an office automation machine, they likely have a proven solution.

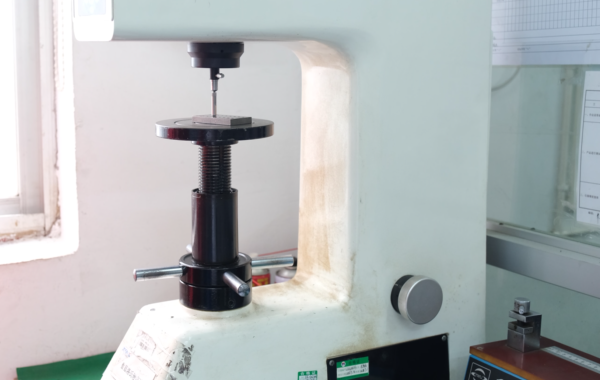

Engineered for Reliability: Zhengke motors are built to last, incorporating high-quality materials and precision manufacturing to ensure consistent performance and reduce the risk of field failures.

Globally Recognized & Supported: Holding mainstream international certifications, Zhengke motors meet global compliance standards. Coupled with a widespread distribution network, you get reliable access and support wherever your operations are.

Final Step: Prototype and Test

The best Micro Motor Selection Guide in the world cannot replace real-world testing. Once you've narrowed down your options based on specs and type, obtain samples. Integrate the motor into your system and validate its performance under actual load, temperature, and duty cycle conditions. A trustworthy supplier will support you through this critical phase.

Selecting the perfect micro motor is a systematic journey from defining your needs to testing the final candidate. By understanding the core technologies, DC motors, BLDC motors, and gear motors, you can effectively navigate the options. Partnering with a capable manufacturer like Zhengke, which offers technical expertise, a complete product portfolio, and volume-ready production capabilities, can de-risk your project and provide a clear path from concept to a successful, reliable product.

Frequently Asked Questions

Q1: What is a brushed DC motor?

What is a brushed DC electric motor? A brushed DC motor has permanent magnets inside its outer body with a rotating armature inside. The permanent magnets are stationary and are called the 'stator'. The rotating armature contains an electromagnet and is called the 'rotor'.

Q2: What are the advantages of using a 24V DC motor?

Therefore, a 24V brushless DC motor is generally more efficient under the same power conditions, since it experiences lower resistive losses and generates less heat compared to a 12V motor. This can translate into better durability and performance in applications where continuous or heavy-duty operation is required.

Q3: How do robot motors work?

Motors and actuators are the devices that make the robot movable. Motors and actuators convert electrical energy into physical motion. The vast majority of actuators produce either rotational or linear motion.

Explore more DC MOTOR solutions and unlock new heights of engineering efficiency! Contact ZHENGKE to get an inquiry and samples right now!