Replacement Suggestions and Alternatives for DC Motors

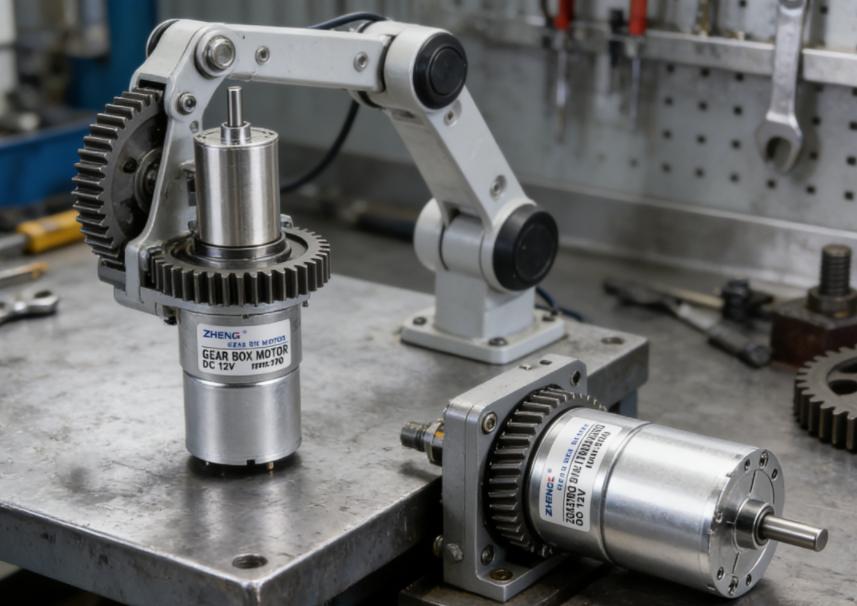

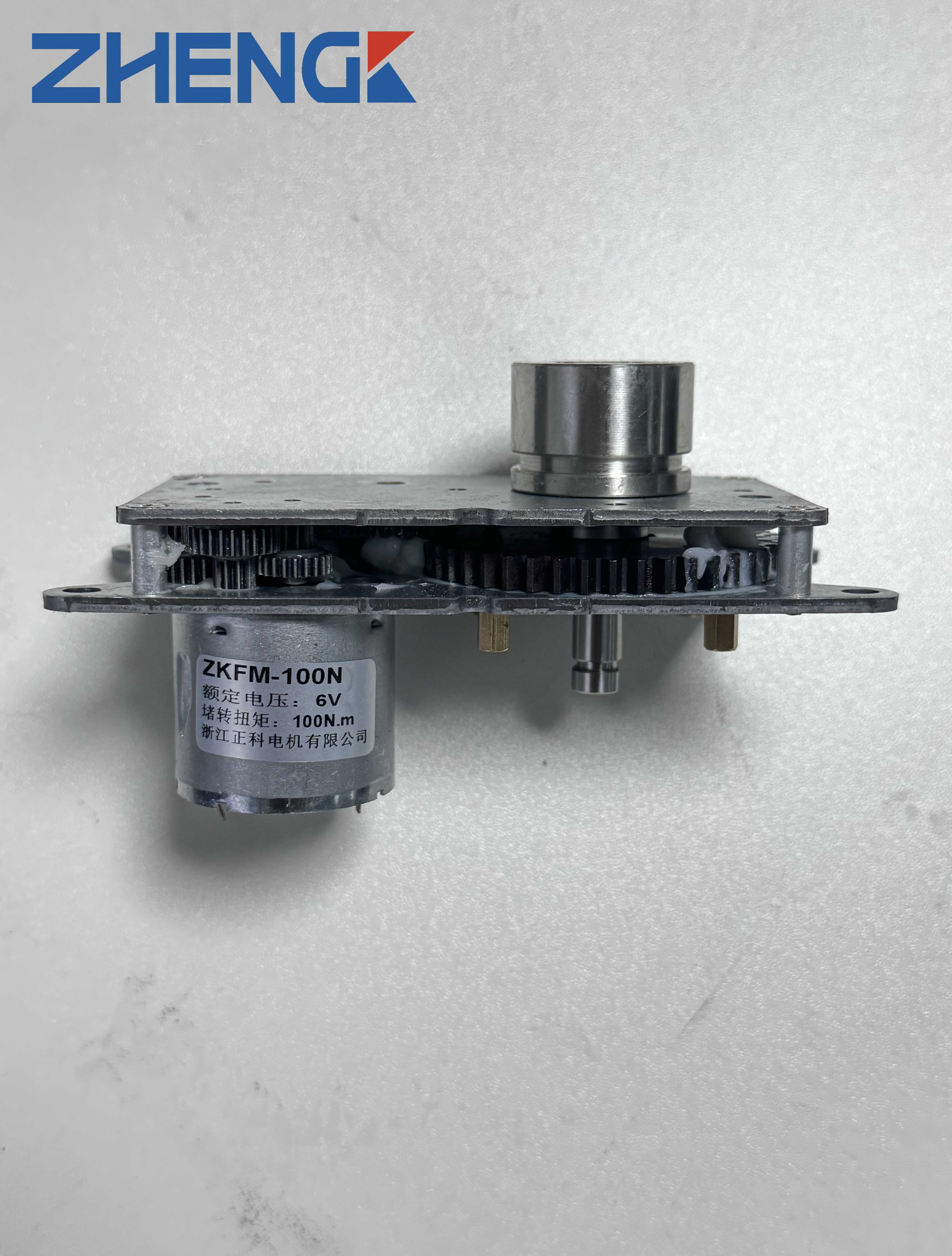

DC motorshave been a core part of industrial and commercial applications for decades. Known for their simplicity, precise speed control, and strong torque at low speeds, Dc Motors are still widely used in many machines and systems. However, as technology evolves, it's important to evaluate whether continuing to use DC motors is the best choice or if it's time to consider modern alternatives.

When Should You Replace a DC Motor?

There are several signs that a DC motor may need to be replaced:

1. Decreased Performance: Slower speed, reduced torque, or overheating can indicate internal wear or electrical issues.

2. Increased Maintenance Needs: Frequent replacement of brushes, bearings, or commutators suggests aging equipment.

3. High Energy Consumption: Older motors are often less energy-efficient compared to modern models.

4. Obsolete Parts: If replacement parts are hard to find or costly, replacing the whole motor may be more economical.

5. Integration Challenges: As automation and smart control systems evolve, older DC motors may not integrate well with new technologies.

Alternatives to DC Motors

Thanks to advances in motor technology, there are several reliable alternatives to DC motors that may provide better performance, reliability, and efficiency.

1. Brushless Dc Motors (BLDC)

Bldc Motors are a modern upgrade over traditional DC motors. They offer:

- Higher efficiency

- Longer lifespan (no brushes to wear out)

- Lower maintenance

- Better speed and torque control

They're ideal for robotics, fans, pumps, and automotive systems.

2. AC Motors (Induction and Synchronous Motors)

For industrial applications, AC motors are often a better long-term solution:

- Rugged and durable design

- Lower operational costs

- Compatibility with modern variable frequency drives for speed control

Induction motors are commonly used in conveyors, compressors, and HVAC systems.

3. Servo Motors

Servo motors are precise and ideal for applications requiring tight position control, such as:

- CNC machines

- Robotics

- Packaging equipment

They are often used where accuracy, feedback, and motion control are critical.

Choosing the Right Replacement

When replacing a DC motor, consider the following:

Application Requirements: Torque, speed, duty cycle, and control needs

Available Power Source: AC or DC supply

Cost vs. Long-term Savings: Consider initial investment versus maintenance and energy costs

Integration with Existing Systems: Ensure compatibility with control systems and mechanical setups

While DC motors are still effective in many situations, today's technology offers smarter, more efficient alternatives. By understanding your system's needs and evaluating available motor technologies, you can reduce downtime, save energy, and improve overall performance.