The Future of Micro Motors in Precision Automation

Compact Size with Practical Performance

Modern automation systems increasingly rely on micro mini Dc Motors to achieve reliable motion within limited installation space. Improvements in manufacturing accuracy and motor design allow these motors to deliver stable speed and torque while maintaining low power consumption. This balance makes them suitable for compact devices that require consistent and predictable operation.

Gear Systems Enable Precise Motion Control

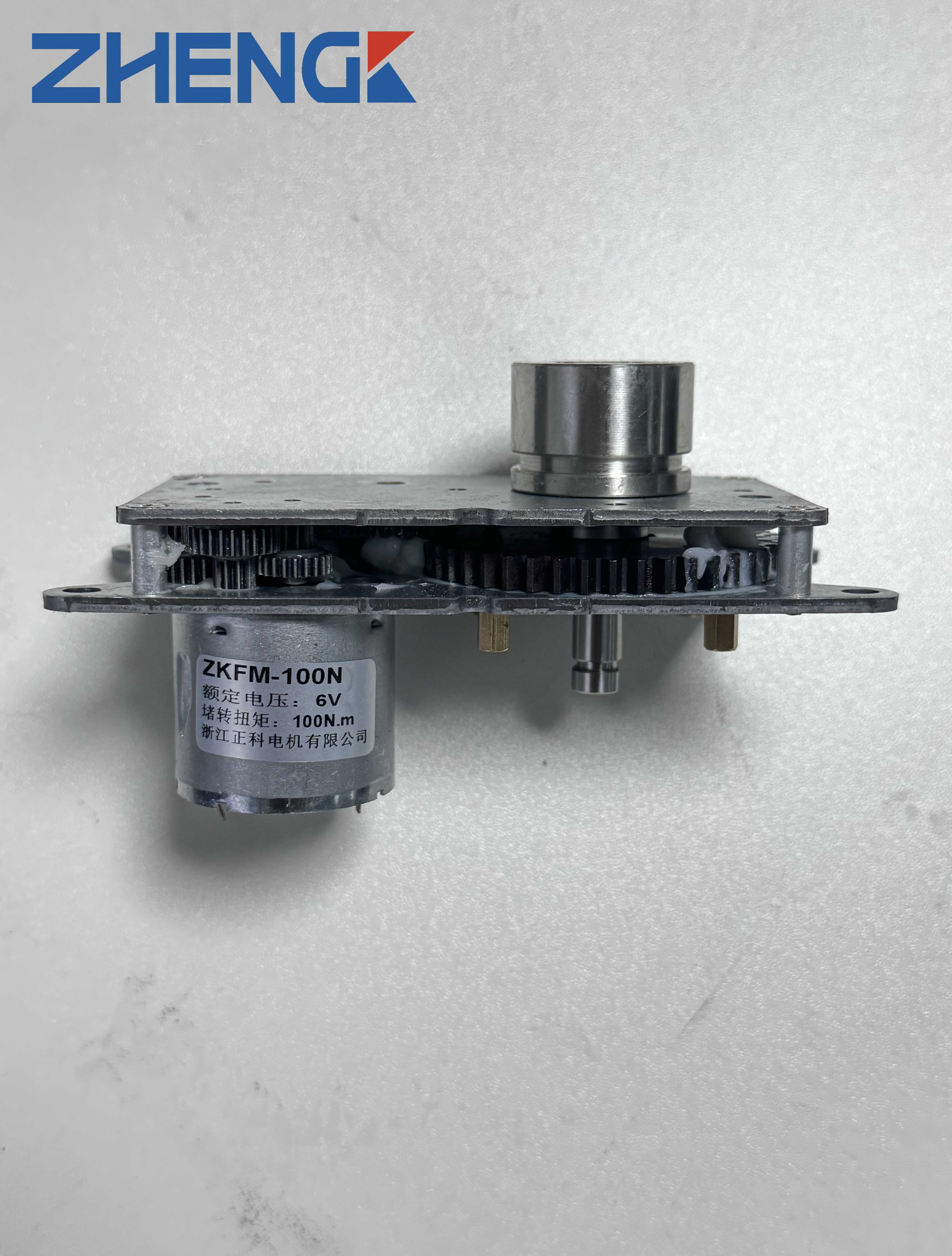

To meet accuracy requirements, Micro Motors are commonly combined with a micro gearbox. Options such as the micro planetary gear motor provide higher torque density and smoother output, supporting applications that demand precise positioning and controlled movement. For systems that require feedback and closed-loop control, a micro gear motor with encoder offers accurate speed and position monitoring.

Practical Use of Brushed DC Technology

The micro brushed DC motor continues to be widely used due to its simple structure, ease of control, and cost efficiency. In many low-voltage and small-scale automation systems, brushed motors remain a practical solution, especially where straightforward control and reliable performance are required.

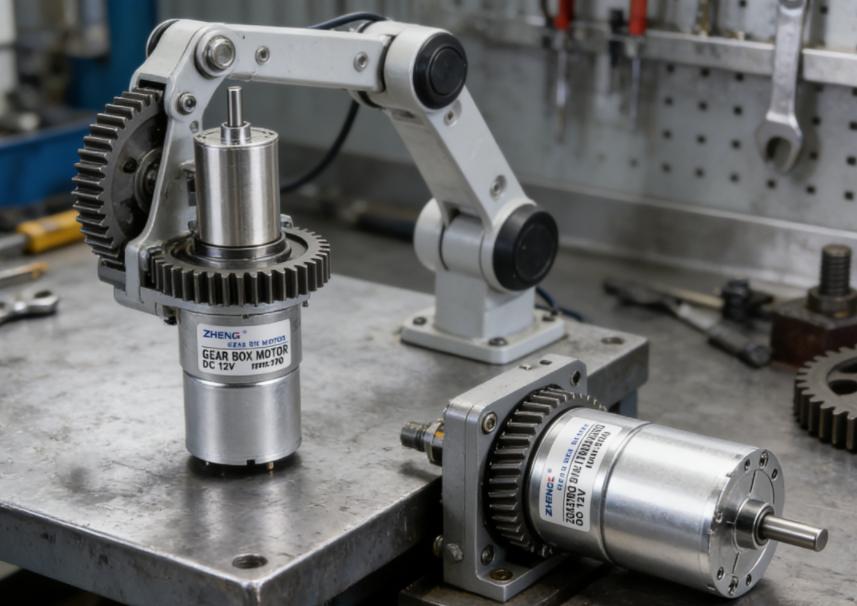

Broadening Automation Applications

Micro gear motors are now applied in a wide range of precision automation fields, including robotics, medical devices, laboratory instruments, optical systems, and smart equipment. The combination of a compact motor and precision gearbox enables smooth operation and long-term stability in demanding working environments.

Toward Smarter and Integrated Systems

With the increasing use of sensors and digital control systems, micro motors are becoming more integrated into intelligent automation platforms. Encoder-equipped micro gear motors support accurate motion control and system coordination, helping improve efficiency and reliability in automated processes.

Precision automation continues to evolve toward smaller, more integrated systems, and micro motors are becoming an essential part of this transition. As equipment designs prioritize compact structures and precise motion control, the role of the micro electric motor has expanded across industrial, medical, and intelligent automation applications.