What are the types of gear motors?

In the field of mechanical engineering, gear reducer motors have always been regarded as critical components, with their success stemming from their practicality. Let's explore the various types of gear reducer motors.

Spur Gear Motors

The teeth of spur gears are typically arranged radially parallel to the shaft axis. The small input gear and the large output gear have only one point of contact at each stage. This meshing structure reduces revolutions per minute (RPM), converting it into torque.

These motors typically produce lower mechanical noise while delivering higher power and efficiency than standard motors. They are manufactured from diverse materials such as steel, brass, and others.

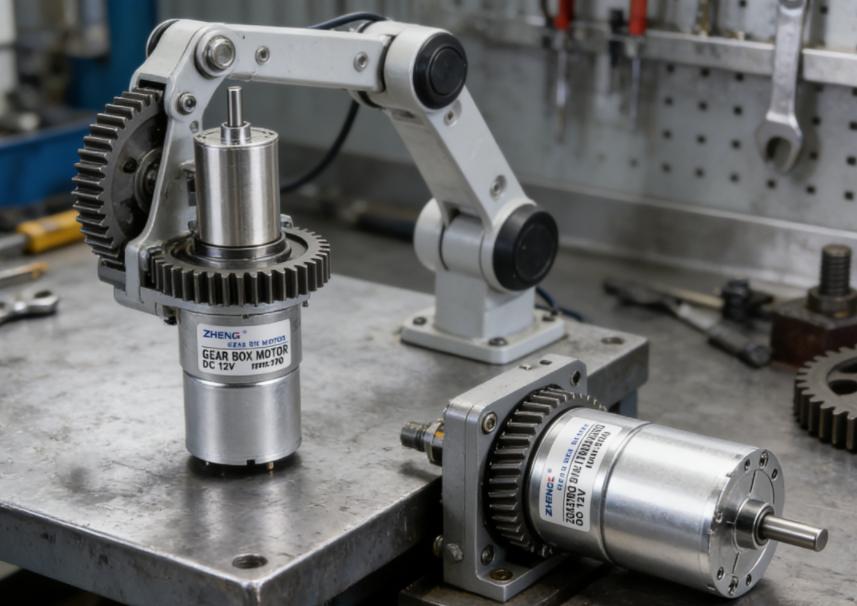

Gear motors find extensive applications across industries, spanning automotive systems to conveyor systems. Key uses include driving conveyor belts, controlling robotic arm movements, and providing mechanical power for vehicle functions like seat adjustment and power windows.

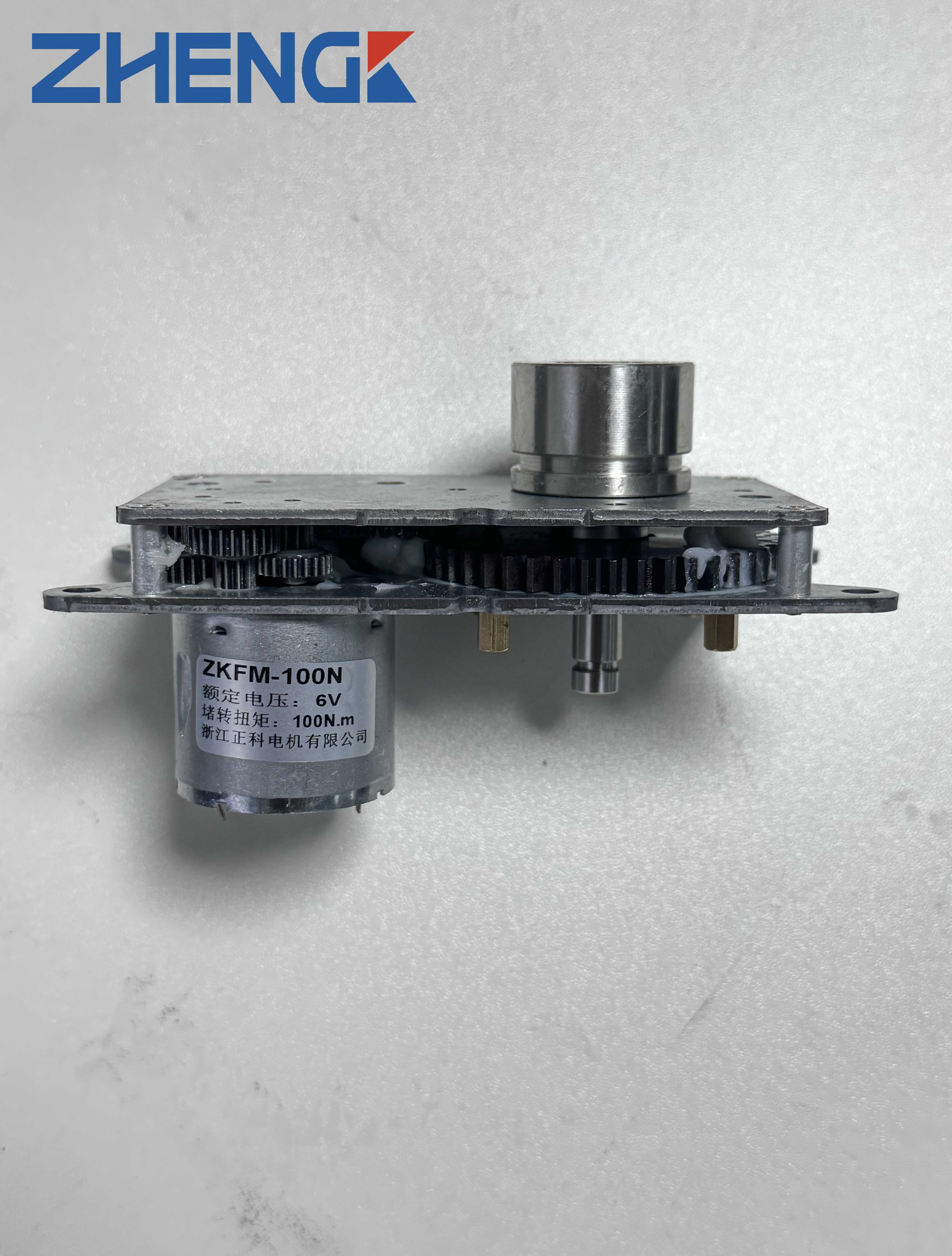

Planetary Gear Motor

As the name suggests, this gear transmission operates similarly to planets orbiting the sun. At the center is a sun gear, around which planetary gears rotate (typically mounted on a carrier). An inner gear, called a ring gear, holds the planetary gears in place as they revolve around the sun gear. Compared to spur gearboxes, this type is designed to deliver higher torque and power within a similar volume. Additionally, these gearboxes offer the advantage of reduced backlash.

By altering the number and size of the planetary gears, the output speed and torque can be adjusted. While spur gears engage at a single point per rotation, planetary gears engage at multiple points, distributing forces to enhance durability and extend service life.

Advantages of Geared Motors

A geared motor consists of a gearbox directly connected to the motor. This means no motor adapters or connectors are required, as the motor's pinion gear meshes with the gearbox's input gear. Eliminating these extra components results in a lighter, more efficient solution with fewer wear parts, reducing the maintenance required for you and your team. Geared motors also offer other key advantages:

Cost-Effectiveness

With low maintenance and installation costs, gear motors often deliver immediate profitability. They also simplify system repairs.

Torque Multiplication

This proves highly advantageous for applications requiring higher torque. Motor size and specifications vary based on purpose. Larger motors power elevators and conveyor belts. Conversely, medical and optical equipment demand smaller, more precise motors due to their operational characteristics.

Speed Reduction

The gears installed within gear motors are sometimes referred to as reducers because they simultaneously increase output torque while decreasing output speed. This reduction enhances system performance, as many motors operate less efficiently at low speeds.

Space Efficiency

Geared motors are often considered a space-saving option. Despite their compact size, these motors still deliver the required torque. This is particularly important in applications with limited space.

Applications of Geared Motors

Geared motors are ideal for applications requiring high output torque and low output shaft speeds, particularly in scenarios with limited space and power constraints. This encompasses a wide range of typical equipment applications across multiple industries.

Robotics

Geared motors are extensively used in the robotics industry, especially for driving various joints such as arms and limbs. Within revolutionary robotic hands, these motors empower actuators with the ability to move freely. The motors also deliver high torque, crucial when robotic hands must lift or support heavy loads. Their exceptional durability effectively withstands wear from repetitive motions, extending the machinery's operational lifespan.

Semiconductor Manufacturing Equipment

Geared motors are extensively deployed in semiconductor fabrication facilities. Equipped with precision-machined gears, these motors enable accurate control and positioning of diverse components, facilitating efficient handling and transportation.

Medical Equipment

Due to their high reliability, gear motors are employed in hundreds of medical devices, such as endoscopes and infusion pumps. Additionally, medical equipment requires quiet operation, necessitating specialized gears designed for noise reduction, such as those made from resin.