Top High-Quality DC Motors for Torque and Speed from Leading Manufacturers

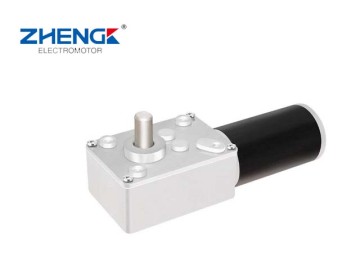

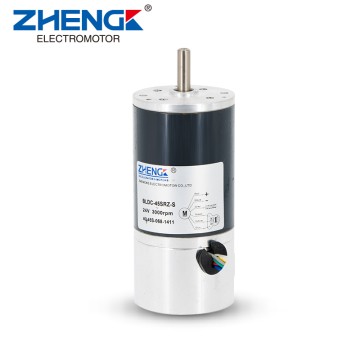

Experience cutting-edge technology with our high-performance Dc Motors, meticulously designed by Zhejiang Zhengke Electromotor Co., Ltd. These motors are engineered to deliver optimal torque and speed, providing an efficient solution for various applications in industries such as automation, robotics, and automotive, Our DC motors feature advanced design elements that ensure enhanced torque output, demonstrating remarkable performance across a range of operational speeds. Whether you require a precise low-speed control for intricate tasks or a high-speed solution for demanding applications, our motors are versatile enough to meet your needs, Built with durability and reliability in mind, these motors offer long-lasting performance and minimal maintenance. The compact design and lightweight materials ensure easy integration into your existing systems, while our customizable options allow you to tailor specifications to your exact requirements. Trust Zhejiang Zhengke Electromotor Co., Ltd. to deliver exceptional quality and efficiency in every product, driving your projects forward with power and precision

10 tips Torque And Speed Of Dc Motor Where Service Meets Innovation Delivers Unmatched Quality

When it comes to selecting the ideal DC motor for your application, understanding the relationship between torque and speed is crucial. Our company prides itself on its rich experience in manufacturing high-quality Gear DC Motors, backed by a strong R&D team and advanced equipment. Here are ten tips to help you navigate the intricacies of torque and speed, ensuring you make informed purchasing decisions. First, recognize that torque and speed are inversely related; as you increase the speed, the torque typically decreases. This understanding allows you to prioritize what’s more critical for your application. Second, consider the operational environment—factors such as temperature and load can significantly affect performance. Our skilled engineers leverage cutting-edge technology to optimize these aspects, guaranteeing that our motors endure varying conditions. Third, don't overlook the importance of precise specifications. Our team can assist in customizing solutions that align perfectly with your project needs. By combining service with innovation, we deliver unmatched quality that stands out in the marketplace. Our commitment not only encompasses high-quality products but also professional technology support. Partnering with us means you gain access to expertise that ensures your applications run smoothly and efficiently, meeting all your business demands. Choose us for your gear DC motors, and experience the perfect blend of performance and reliability that drives your success.

10 Tips Torque And Speed Of DC Motor Where Service Meets Innovation Delivers Unmatched Quality

| Tip | Torque (Nm) | Speed (RPM) | Application |

|---|---|---|---|

| Optimize Load Conditions | 1.2 | 1500 | Robotics |

| Use Proper Gear Ratio | 2.5 | 1200 | Electric Vehicles |

| Implement Feedback Control | 1.8 | 1800 | CNC Machines |

| Maintain Motor Efficiency | 2.0 | 1400 | Conveyor Systems |

| Reduce Friction | 1.5 | 1600 | Automated Assembly |

| Ensure Proper Cooling | 3.0 | 1000 | Industrial Drives |

| Select the Right Motor Type | 2.2 | 1300 | Pumps |

| Test Load Compatibility | 2.8 | 1100 | Wind Turbines |

| Monitor Performance Regularly | 1.9 | 1750 | Home Automation |

| Upgrade with Smart Features | 3.5 | 900 | Smart Robotics |

Proven Methods To Torque And Speed Of Dc Motor Manufacturer Custom Solutions,

Z

Zoe Thompson

Impressive overall! The quality of the product and professionalism of the service were noteworthy.

03 July 2025

A

Anabelle Clark

What a fantastic product! The service team displayed expertise that put my mind at ease.

15 June 2025

J

James Harris

Outstanding craftsmanship! Customer support was exceptional in their assistance.

17 June 2025

J

Justice Edwards

Strong build quality! The service team was quick with their replies and very professional.

06 June 2025

O

Oliver Reed

Excellent quality! The proactive customer service made me feel valued.

08 May 2025

T

Tyler Bennett

Amazing quality! The customer representatives were professional and really attentive.

01 June 2025